Control Systems

Pilot Series for Machinery and Plant Solutions

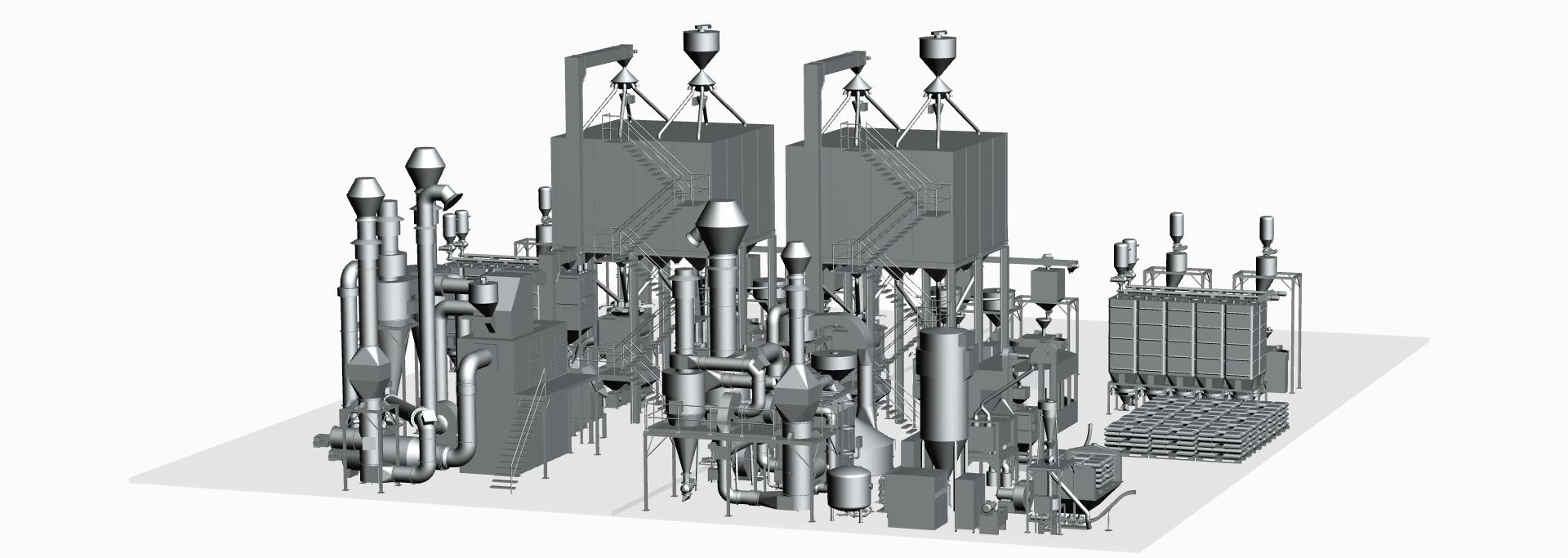

Green coffee, roast and ground coffee, different production varieties, frequent recipe changes and blend variants: coffee always behaves differently depending on the conditions. PROBAT controls are tailored to batches or continuous processes and are designed to deal with the wide variety of this natural product. PILOT control systems are available at different upgrade levels, ranging from the basic version with semi-automated control, which is designed for small production systems and independent production areas, to the comprehensive total plant control system with integration of all key production-related areas of the plant.

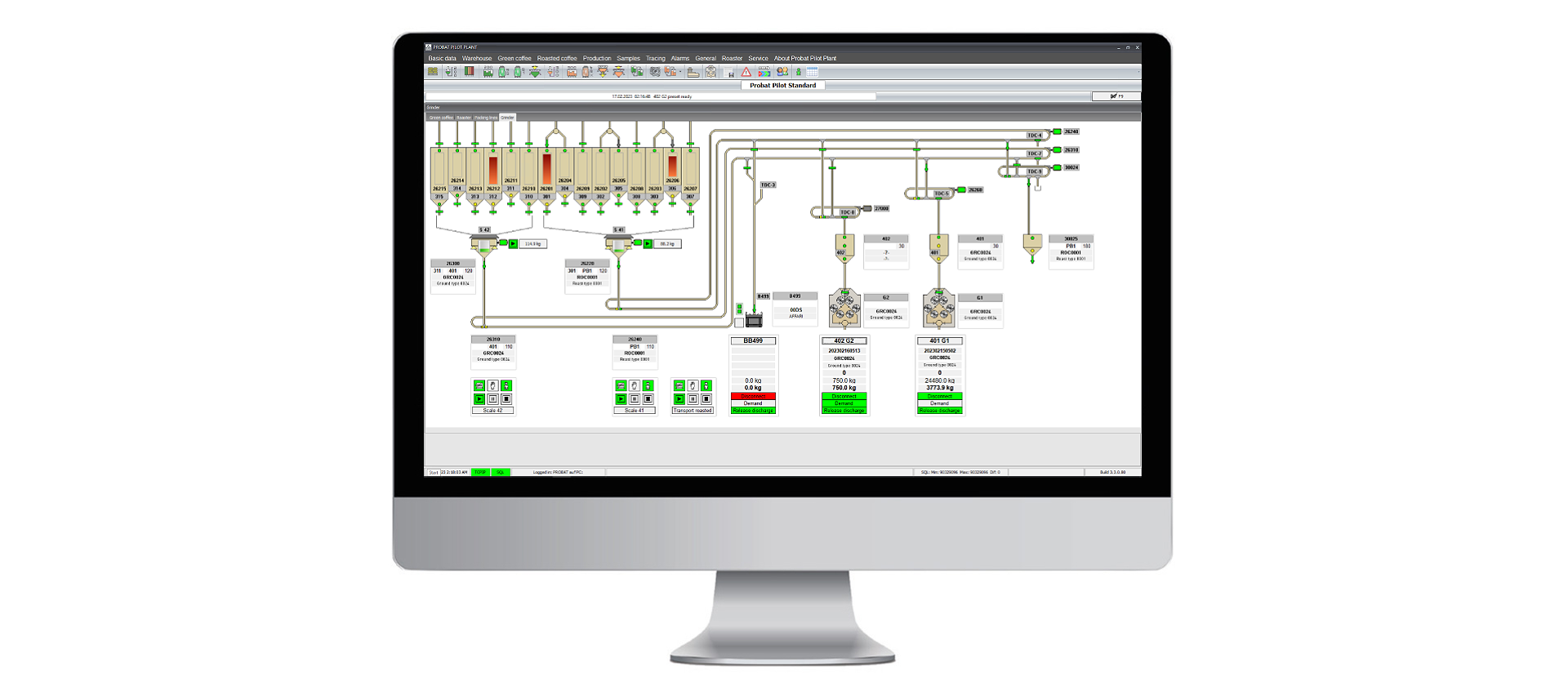

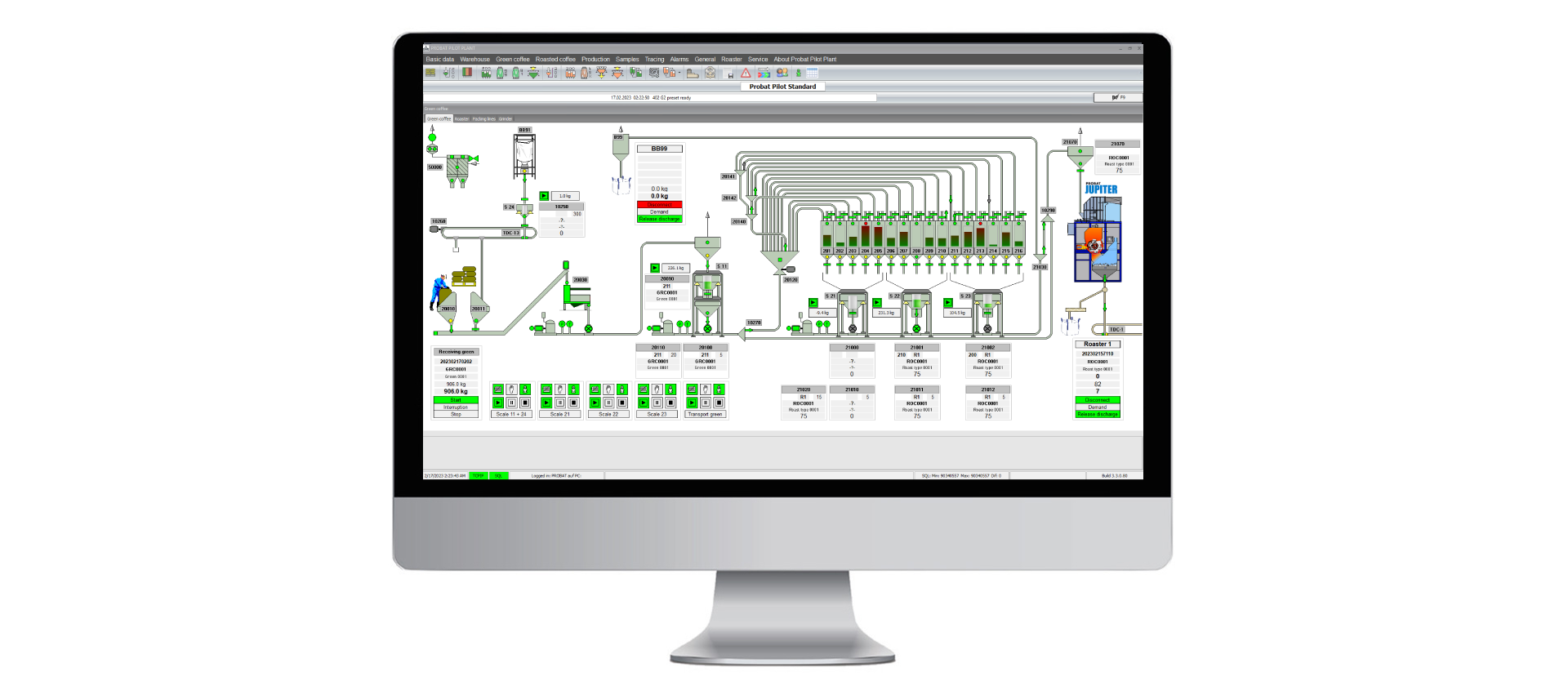

The PILOT PLANT series comprises state-of-the-art solutions for controlling and monitoring coffee production plants. The series ranges from a basic version with semi-automatic control for small production plants and independent production sections to comprehensive overall plant control with integration of all plant components important for production. The latest versions of PILOT PLANT Standard and Excellence can be connected to the customer's ERP system, ensuring real-time communication throughout the entire process.

The PILOT PLANT control solutions are characterized above all by the fact that they ensure faster, more efficient and safer processes. All plant components including the PROBAT roasters and grinders can be operated fully automatically.

The selection of different equipment features and functions is very high. Depending on the individual design of the plant and the selected control version, different solutions are possible. Further plus points are the detailed and fast traceability along the entire value-added process, the comprehensive quality management and reporting as well as the maximum security through a user administration and a clear alarm system.

Probat Pilot Control Systems

The PILOT control systems consist of high-quality hardware and software that guarantee maximum production reliability and efficiency. There is a choice of different control solutions and operating concepts to meet the respective customer requirements.

PILOT control systems are available in the following model variations:

- PILOT 2020 ROASTER (semi-automated control with touch panel)

- PILOT 2020 ROASTER (fully-automated control with PC-based visualization; can be integrated into the total plant control concept PILOT PLANT)

- PILOT 2020 GRINDER Excellence (fully-automated control with touch panel; can be integrated into the total plant control concept PILOT PLANT)

- PILOT PLANT Basic Version 3 (touch panel solution for independent production areas)

- PILOT PLANT Standard Version 3 (predefined solution focused on automation)

- PILOT PLANT Excellence Version 3 (tailored, maximum solution with centralized operation)

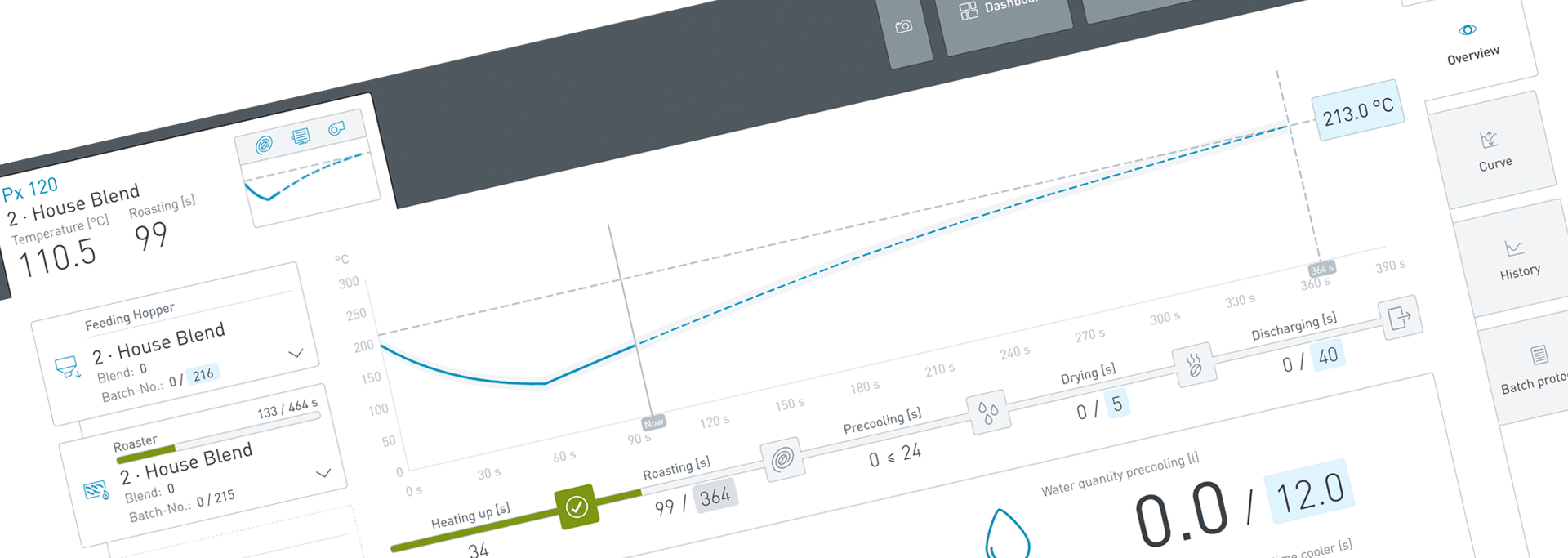

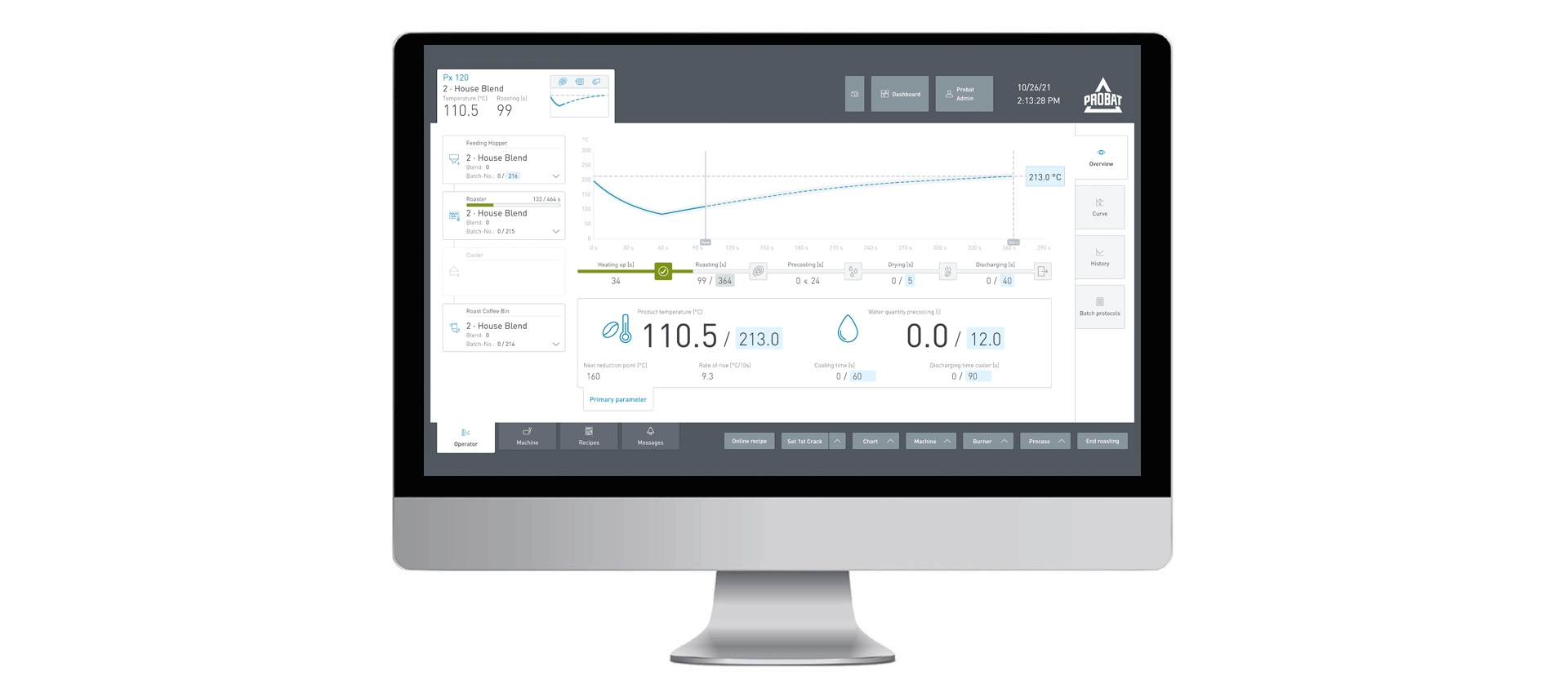

THE PIONEERING CONTROL SOLUTION PILOT 2020 ROASTER

The next-generation control solution PILOT 2020 ROASTER is a web-based application which features an intuitive HMI, enabling roasters to modify vital roasting parameters by touch. Roasting profiles can be compared and reproduced, thus making their optimization easier. PILOT 2020 ROASTER is programmed using modern web technologies such as HTML5 and JS, which allows access from different devices and operating systems. The application was built from scratch, with a touch-optimized interface that provides a completely new user experience focusing on essential information to monitor and control the roasting process.

Created for demonstration purposes, the PILOT 2020 ROASTER click dummy gives you an insight into how this next-generation control solution ensures highly efficient processes as well as increased quality and productivity. Go to https://pilot2020.probat.com/ and convince yourself!

Arrange your online consultation appointment with one of our experts. Select the preferred date and time and we will simply and easily book your personal Teams meeting with your direct contact person.

For price inquiries or if you just need a short information, please get in touch with your respective contact person or your country representative by phone or email.