Coffee

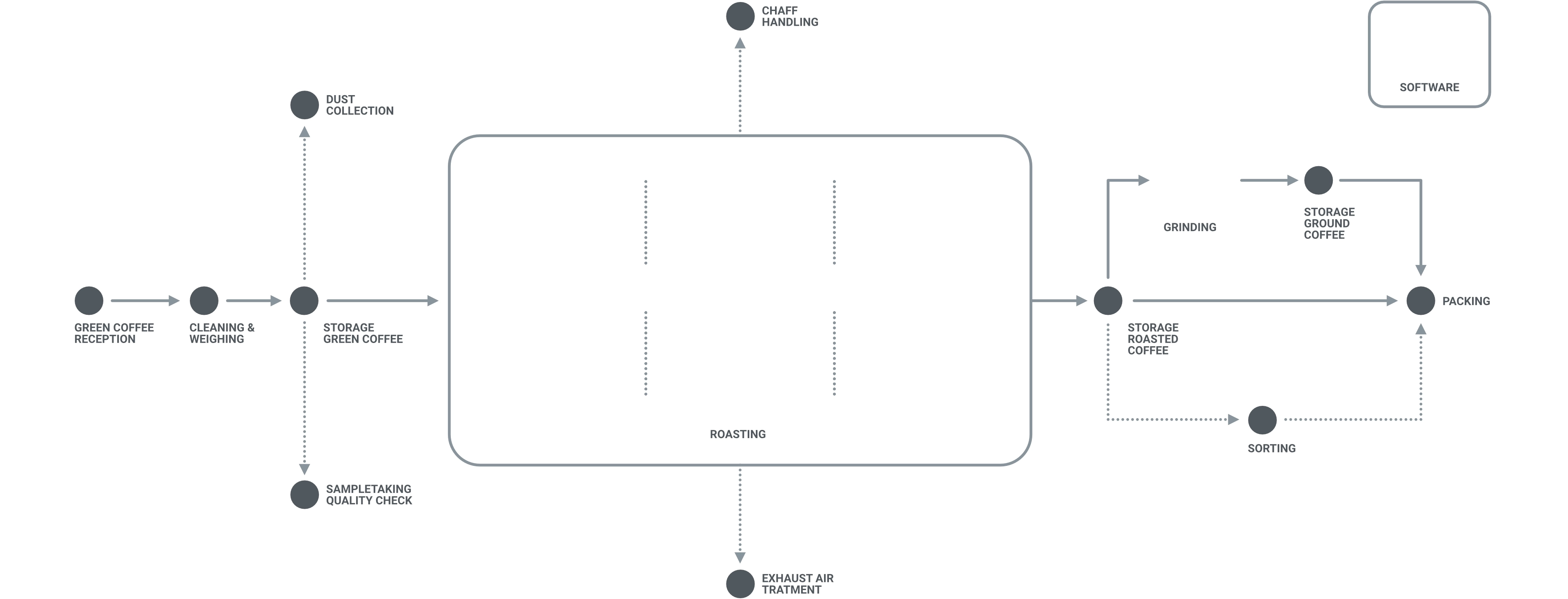

From green coffee intake to roasted or ground coffee storage, PROBAT delivers customized roasting solutions that center on the final product and ensure seamless integration and coordination across all components. Our expertise spans every stage – from energy efficiency and process optimization to safety strategies, emission control, noise reduction, and comprehensive factory layout design. Driven by innovation and always focused on your needs, we help you maintain a lasting competitive edge.