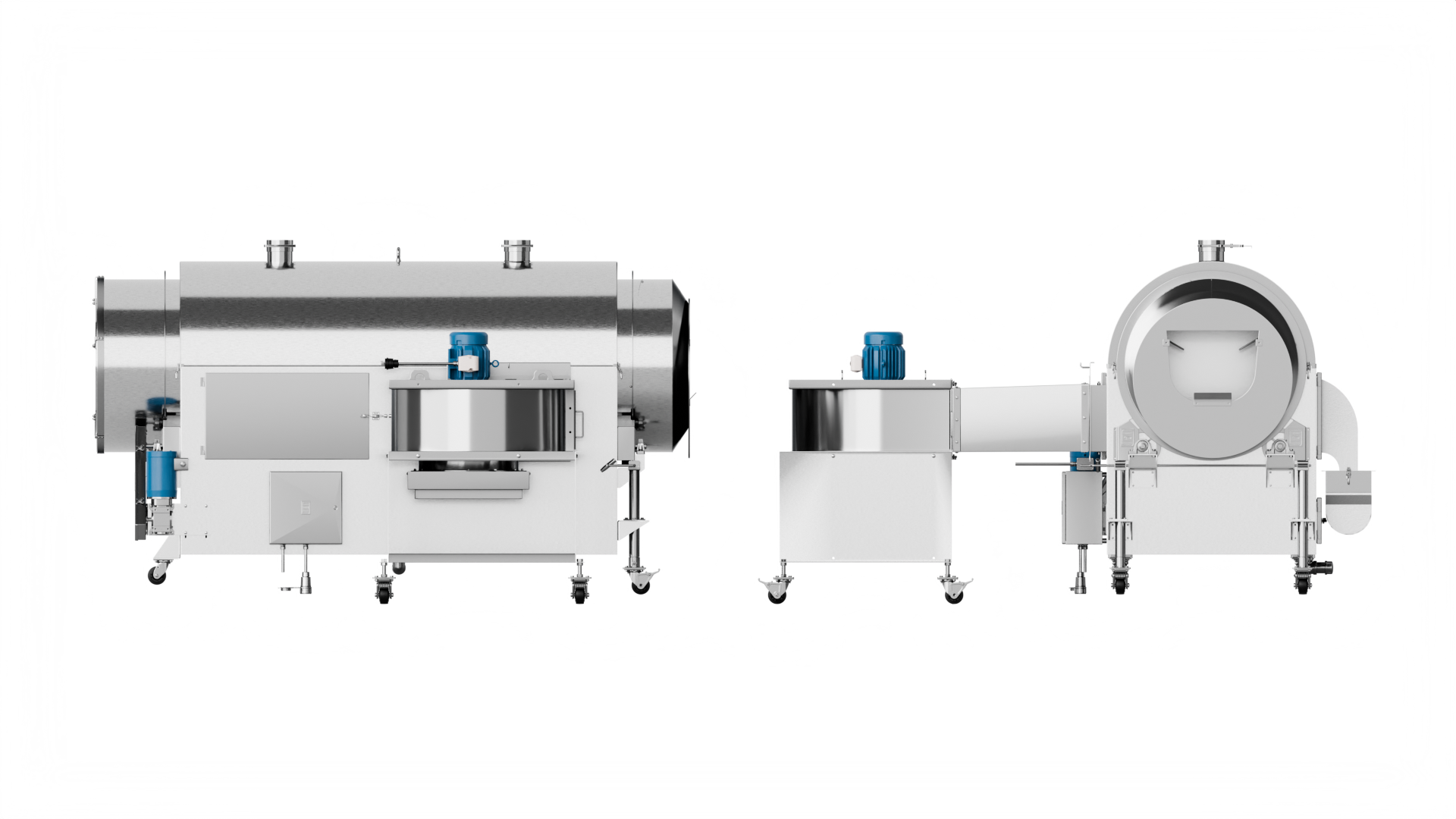

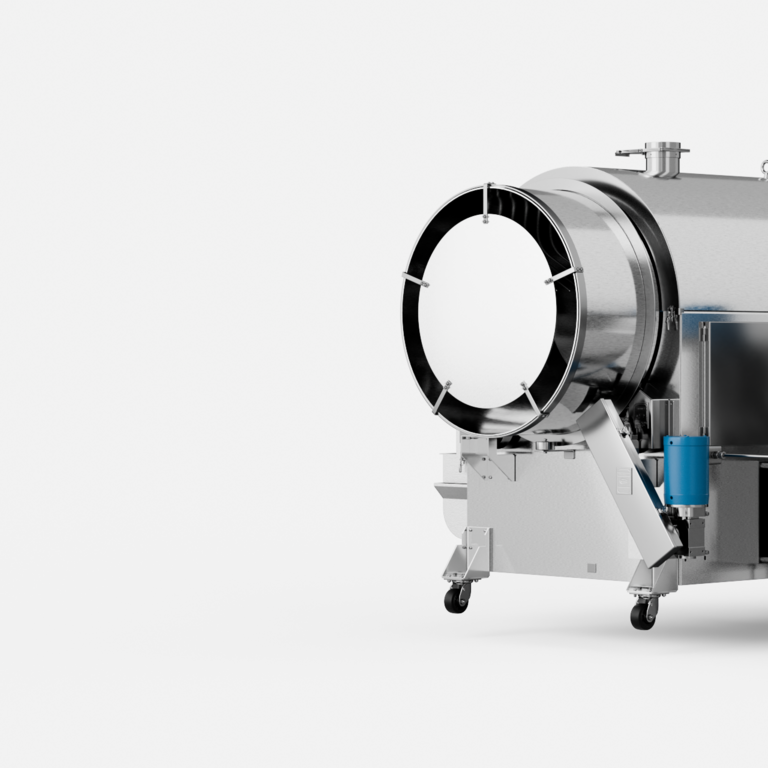

416 Rotary Cooler/Separator

Cooling and Separation of Popcorn

Maximum Product Quality

- The rotating drum and ambient air system ensure rapid cooling and gentle separation of coated popcorn, preserving product quality and texture.

Seamless System Integration

- Designed to integrate effortlessly with Horn’s M360 and M205 Cooker/Coater systems, the 416 Rotary Cooler/Separator supports scalable, high-capacity production lines with consistent performance.

Maximum Availability

- The blower motor’s mobile, wheeled platform allows for quick removal, simplifying cleaning and maintenance to reduce downtime.

Built to solve. Designed to deliver.

The Horn 416 Rotary Cooler/Separator is precisely engineered to efficiently cool and separate freshly coated popcorn, ensuring excellent product quality and ease of handling. Ideally suited for high-capacity production, it integrates seamlessly with Horn’s M360 or M205 full-line Cooker/Coater systems, making it the perfect solution for processors aiming to increase throughput without compromising consistency or reliability.

After the coating process, the caramel corn is gently transferred onto a collection conveyor and fed into the M416 Rotary Cooler/Separator. Within the rotating drum, stainless steel fingers carefully tumble the product while ambient air circulates throughout the chamber, rapidly and uniformly cooling and separating the popcorn.

For maximum convenience, the blower motor is mounted on a separate wheeled platform, allowing for quick, tool-free removal during cleaning and maintenance – minimizing downtime and enhancing overall operational efficiency.