BLB Blocking Line Butter

Cooling and Tempering

Efficient and Uniform Cooling

- A countercurrent cooling system combined with rotating scraping rollers ensures rapid, uniform cooling and consistent tempering of cocoa butter.

Versatile Application

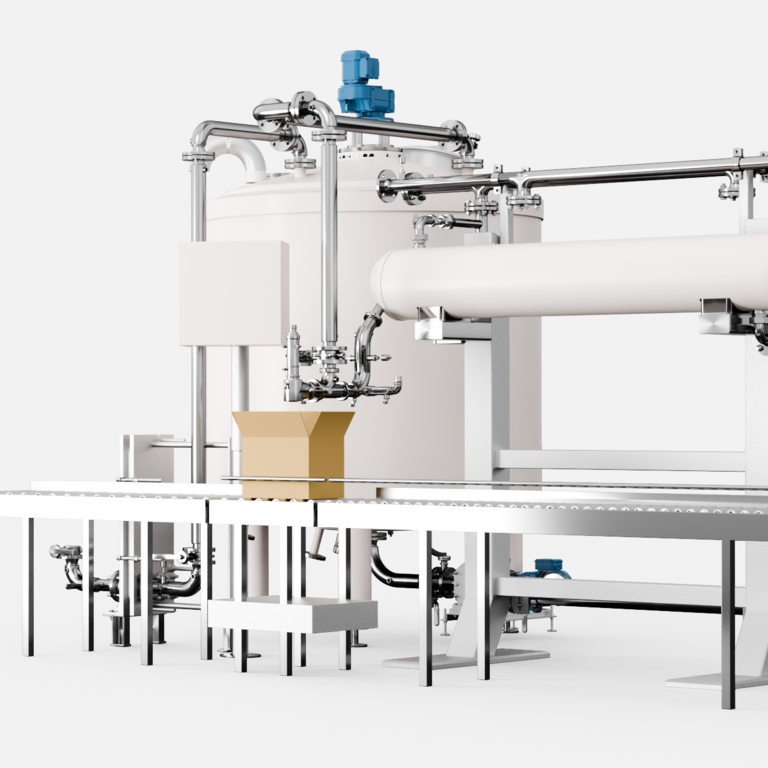

- Suitable for processing not only cocoa butter but also cocoa liquor, chocolate, and similar formulations, with precise dosing and flexible filling options.

Optimized for Packaging

- Delivers butter in a near-solid state, enabling smooth filling into trays or cartons and complete solidification for easy palletizing.

Built to solve. Designed to deliver.

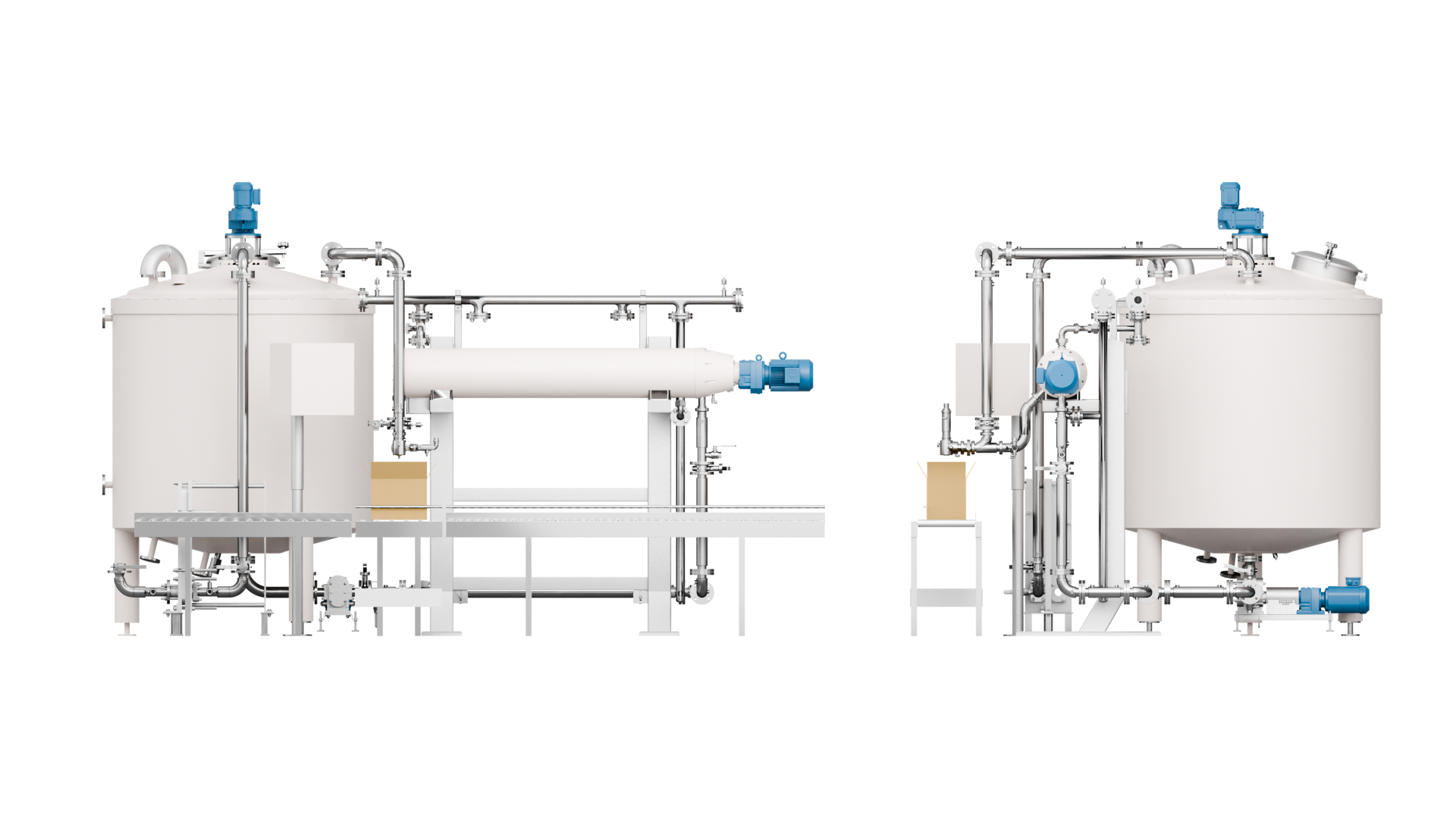

Designed for the production of pure prime pressed or deodorized cocoa butter, the Duyvis BLB Blocking Line Butter ensures optimal cooling and tempering before filling. This system is also ideal for cooling cocoa liquor, chocolate, and similar formulations, with precise dosing and filling into trays or cartons.

Cocoa butter is pumped between a water-cooled rotating drum and the cooler housing, operating on the countercurrent principle for maximum efficiency – where butter and cooling water flow in opposite directions.

Crystallization occurs on the walls of the cooling tubes. Rotating scraping rollers ensure continuous mixing with already crystallized butter, producing a consistently tempered product.

The butter cooler delivers rapid, uniform cooling, preparing cocoa butter for smooth filling and solidification before pallet packaging.

Versions

| BLB 750 | BLB 3000 | |

|---|---|---|

| Capacity [kg/h] | 500–700 | 2,250–3,000 |

| Connected load [kW] | 17 | 19 |