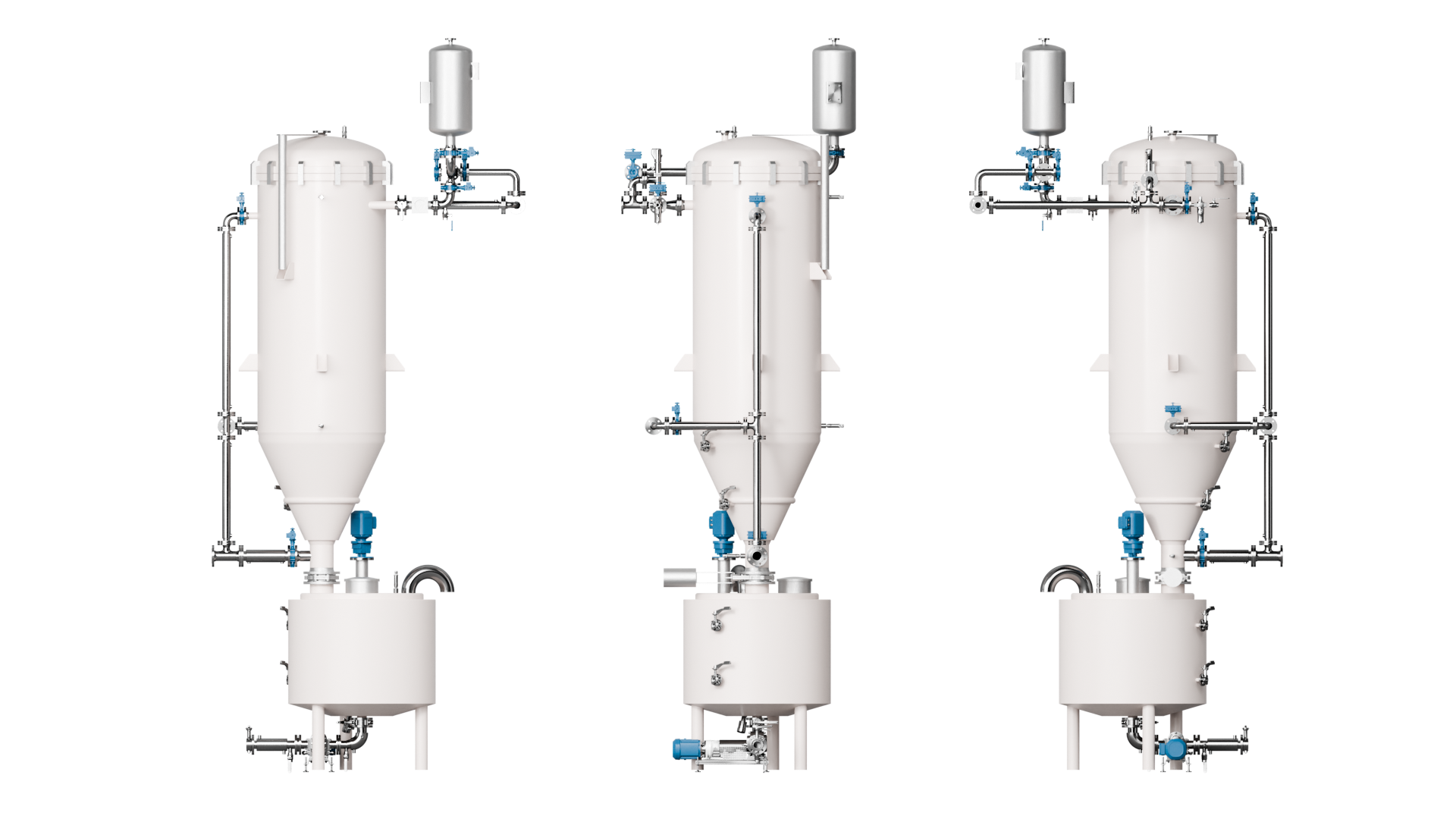

CFB Continuous Filter Butter

Cocoa Butter Filter

Maximum Product Quality

- Effectively removes residual cocoa solids to deliver crystal-clear butter, ready for further processing.

Maximum Availability

- Automatic backwashing and cycle restarting ensures consistent filtration with minimal downtime.

Maximum Yield

- Captures and recycles cocoa solids back into production, reducing waste and maximizing yield.

Built to solve. Designed to deliver.

When cocoa butter exits the press, it still contains fine cocoa solids. The Duyvis CFB Continuous Filter Butter system is specifically designed to continuously clean and clarify this crude butter within a fully enclosed, automated process.

The butter enters a filtration tank, where the solids form a thin filter cake on the cloth surfaces, while the purified butter passes through specialized filter candles. As the solids accumulate, the system automatically initiates a backwashing cycle, directing the residues to the conical bottom of the tank.

Once the solids reach their collection limit, they are discharged and returned to the liquor storage or grinding system for reuse. The filtration process then restarts automatically, ensuring a continuous flow of crystal-clear, high-purity cocoa butter – ready for deodorization or direct packaging.

Versions

| CFB 3300 | |

|---|---|

| Capacity [kg/h] | 2,400–3,300 |

| Connected load [kW] | 8 |