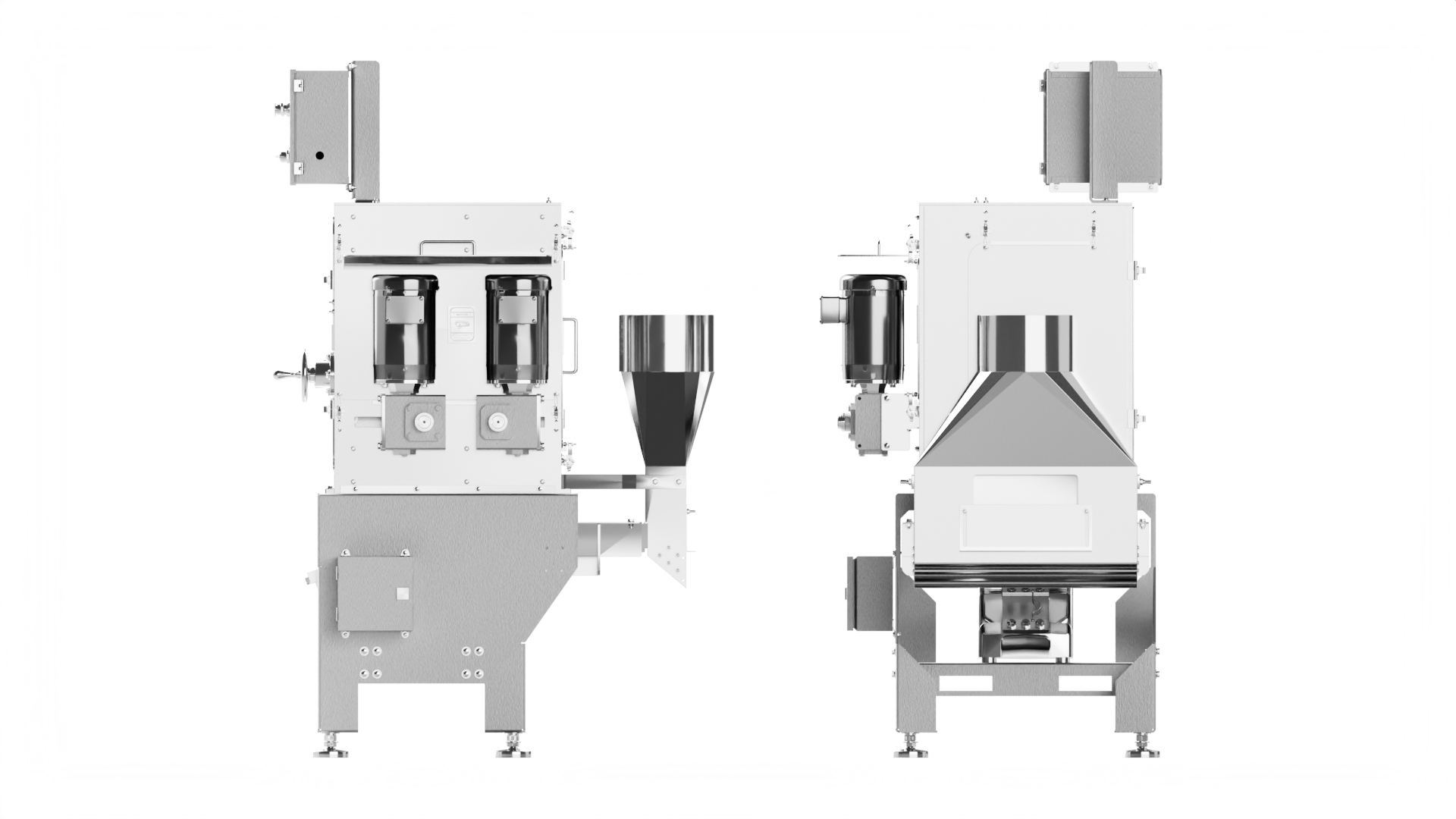

VB Split Peanut Blancher

Peanut Blancher

Exceptional Product Quality

- The precise splitting of peanuts and removal of skins and hearts ensures high-quality end products.

High Efficiency and Throughput

- A high processing capacity with minimal shrinkage ensures maximum yield and productivity.

Maximum Product Flexibility

- Dual-stage aspiration, efficient screening and an adjustable feed hopper enable precise control and optimal product flexibility.

Built to solve. Designed to deliver.

The Horn VB-5000 Split Peanut Blancher is expertly engineered to efficiently remove skins from dried or fully roasted peanuts while separating the kernels, resulting in exceptionally smooth, clean, and visually appealing nuts.

Designed for precision and efficiency, the VB-5000 first splits the peanuts and removes their skins, then separates the hearts from the halves. A combination of screening and dual-stage aspiration ensures complete and thorough skin removal throughout the process. Key features—such as an easily adjustable feed hopper and a robust aspiration system—enable optimal performance for peanuts destined for peanut butter, confectionery, and similar applications.

With a processing capacity ranging from 900 to 2,300 kilograms per hour, the VB-5000 offers superior yield with the lowest shrinkage rate in its class.

Versions

| Versions | VB-5000 |

|---|---|

| Capacity [kg/h] | 2,200 |