Dust Extraction

Filtering of process air in green coffee transport

Maximum Cleaning Efficiency

- Extracting and multi-stage filtering the process air reduces dust particles to a minimum, guaranteeing maximum cleaning efficiency.

Maximum Safety

- Removing dust-laden air by negative pressure reduces explosive atmospheres and guarantees maximum safety for people and machinery.

Maximum Availability

- Reduced cleaning and maintenance work extends the life cycle and guarantees minimum downtime.

Built to solve. Designed to deliver.

Dust generated during exhaust air cleaning and material handling can pose serious health risks. In coffee processing plants, especially in green coffee systems, efficient dust extraction is essential. PROBAT offers a range of custom-designed Dust Extraction systems, developed to meet project-specific conditions and requirements, ensuring that dust-related air pollution during green coffee transport is reduced to an absolute minimum.

Under certain conditions, seemingly harmless dust clouds can ignite, creating jet flames and explosive pressure waves. To counter this risk, the Dust Extraction systems are engineered with integrated pressure relief technology, minimizing the effects of any potential dust explosion.

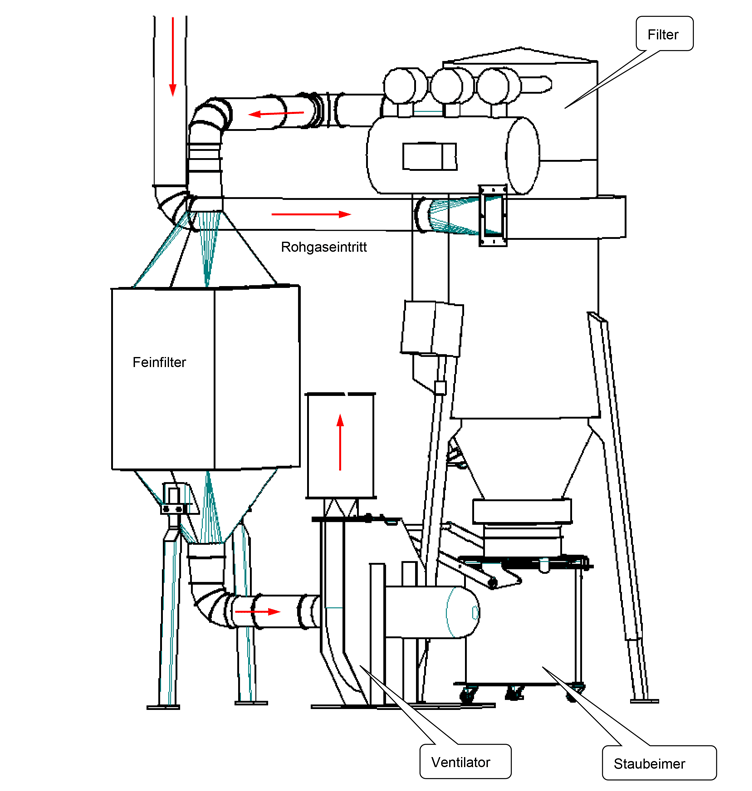

A powerful fan generates negative pressure, drawing dust-laden air out of the pipework system and directing it into a multi-stage filter system. In the first stage, air enters a filter chamber where coarse particles larger than 10 µm are captured by a filter bag and collected in a dust bucket; in the second stage, finer particles between 1 and 10 µm are separated in a downstream fine filter; and for maximum air purity, an optional third stage can be added with a HEPA filter to capture ultra-fine particles smaller than 1 µm.

With the Dust Extraction solutions, you can ensure a safer, cleaner working environment and optimize plant safety and compliance.