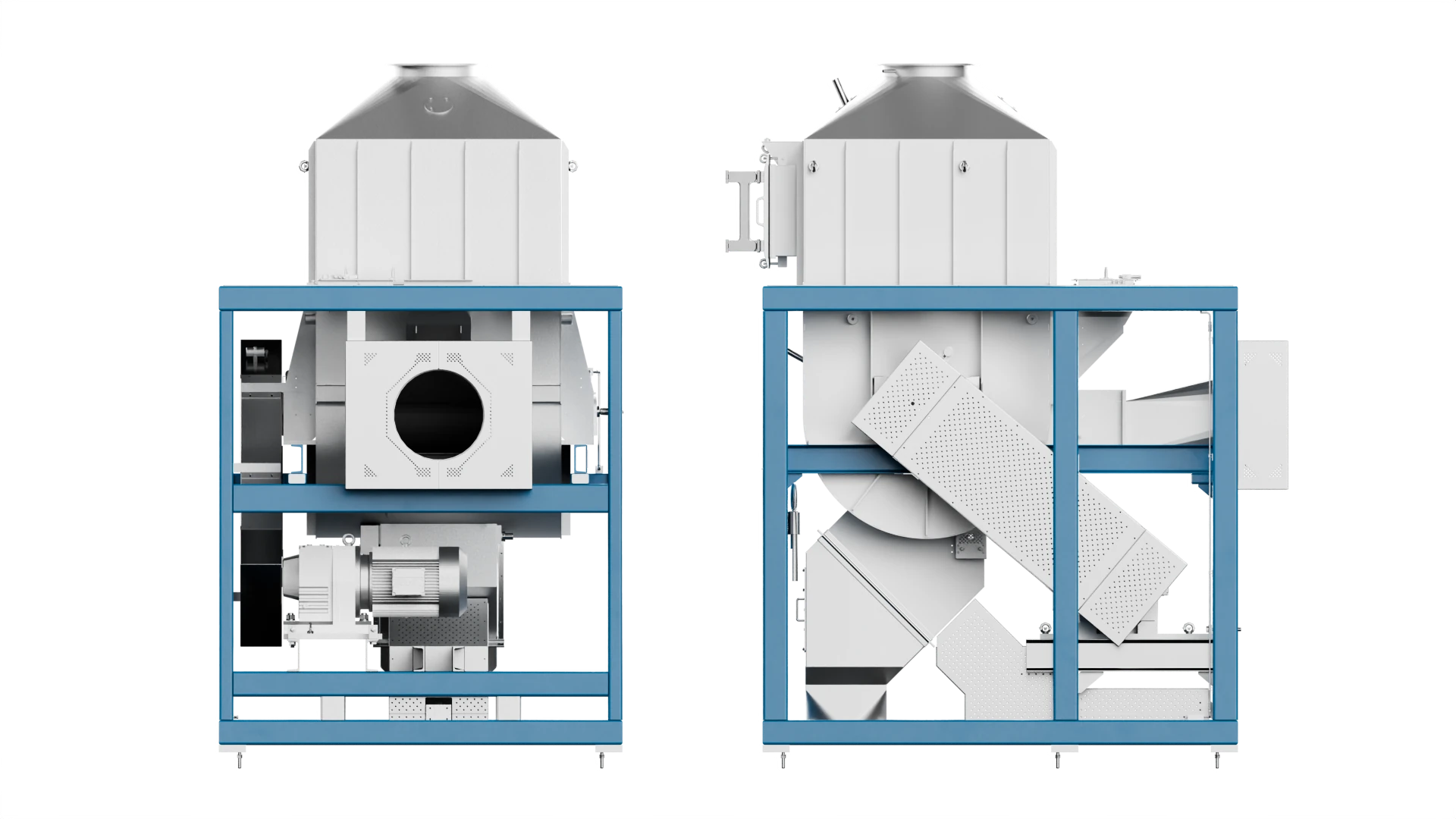

RKV

Preheating of green coffee prior to roasting

Maximum Energy Efficiency

- Utilizing excess energy from the process exhaust air ensures energy savings of around 20% in the downstream roasting process.

Enhanced Productivity

- Simultaneous roasting and preheating reduce cycle times and increase production output.

Maximum Product Quality

- The movement of the coffee beans along defined paths ensures they are mixed evenly and ensure homogeneous heat transfer.

Built to solve. Designed to deliver.

The RKV green coffee preheating system is positioned upstream of the roaster and operates without the need for additional heating energy. By utilizing excess heat from roasting exhaust air, the RKV significantly reduces energy consumption and shortens roasting cycles – all while increasing production output through simultaneous drying and roasting.

In conventional roasting, green coffee is loaded cold into the preheated roaster, causing a sudden temperature drop as the beans absorb heat. This requires extra energy to restore the system’s temperature and initiate the drying phase. The RKV eliminates this energy-intensive step: green coffee is gently preheated in a dedicated container to temperatures of up to 100 °C, using a portion of the cleaned exhaust air. Continuous mechanical mixing ensures uniform heat distribution across all beans, perfectly preparing them for roasting.

Once preheated, the beans are swiftly transferred to the roaster, significantly reducing the time to reach the critical browning and flavor development stages. This process not only improves overall energy efficiency but can also boost roasting capacity by up to 20%.

-

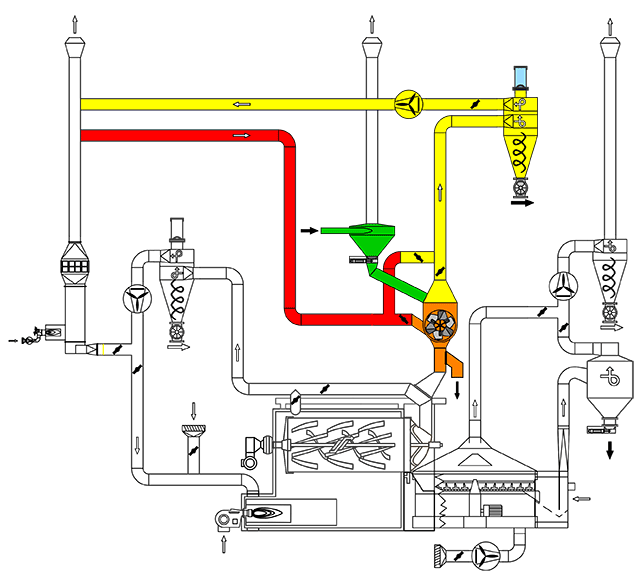

Neptune with RKV