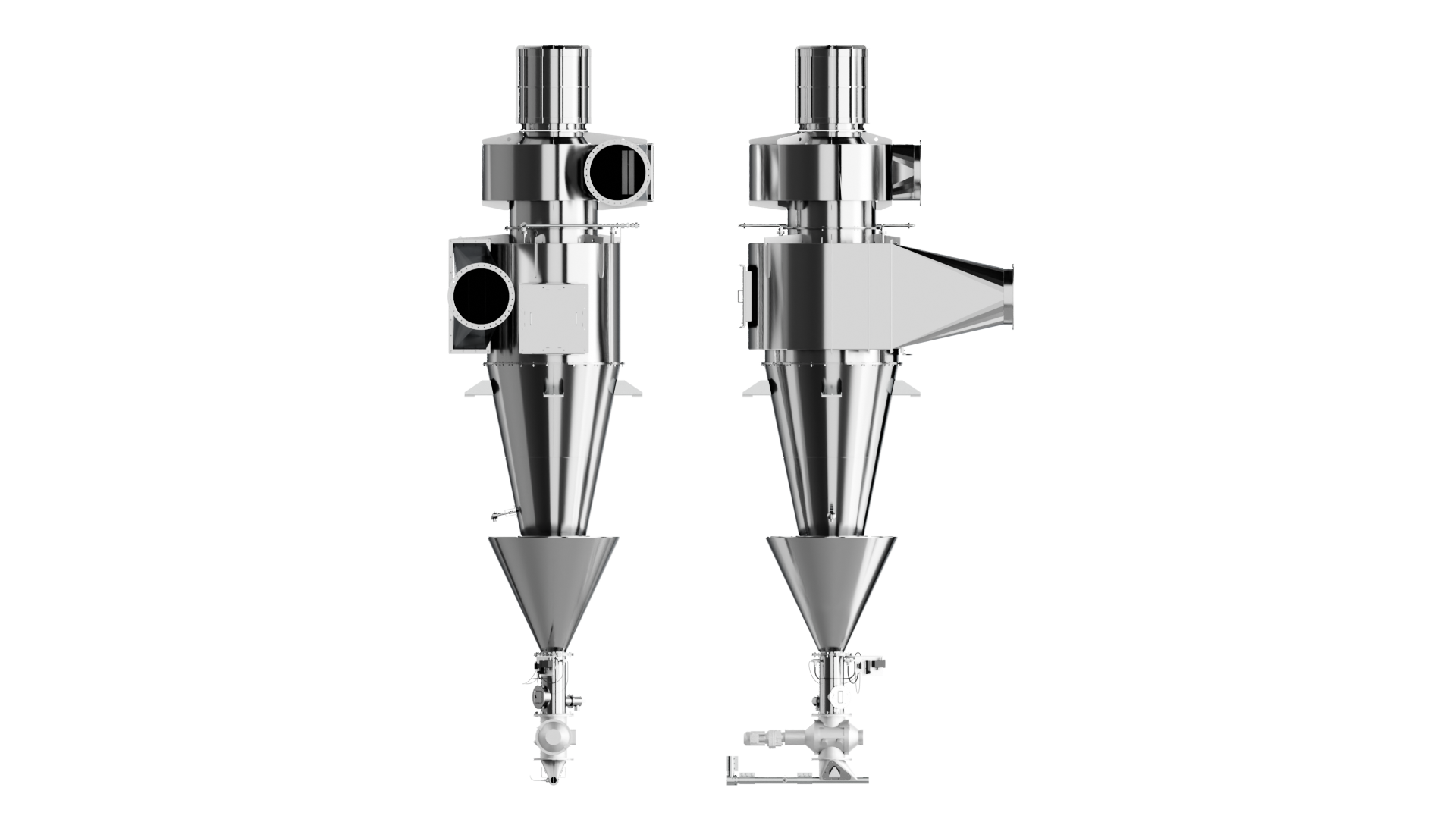

High-Performance Cyclone

Treatment of roasting, cooling and destoner exhaust air

Maximum Cleaning Efficiency

- The centrifugal force generated by the spiral airflow ensures the optimum separation of coarse and fine particles, guaranteeing maximum separation efficiency.

Maximum Dust Removal

- The exceptionally high purification efficiency guarantees emission limits of 20 mg/m³ of dust in the exhaust air.

Enhanced Energy Efficiency

- The optimized flow geometry guarantees high energy efficiency.

Built to solve. Designed to deliver.

PROBAT's high-performance cyclones deliver highly effective and energy-efficient exhaust air purification, ensuring optimal particle separation and maximum cleaning results. Designed for exhaust air treatment in roasting, cooling and de-stoning processes, these cyclones provide a reliable and sustainable solution for maintaining clean air in your roasting operation.

The cleaning process begins when exhaust air is fed in at high speed at an angle into the upper section of the cyclone’s conical chamber. As the air spirals downwards, centrifugal force propels larger particles towards the outer walls and directs them to the cone tip for removal. Meanwhile, finer particles are carried upwards and discharged separately, ensuring highly efficient separation.

To further improve air quality and system efficiency, an optional filter system with a separate fan can be integrated into the cyclone’s exhaust air duct.