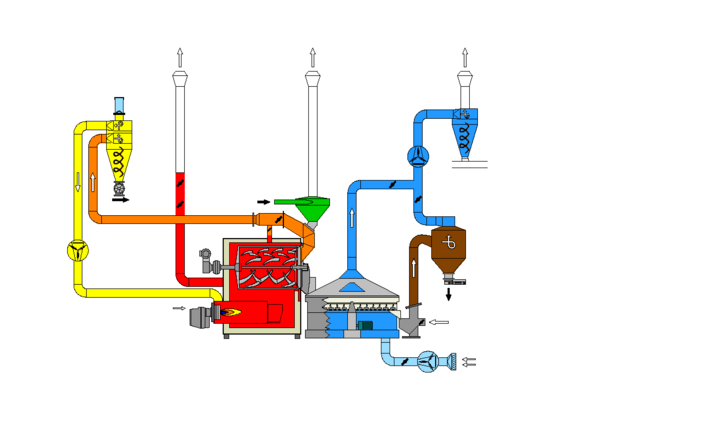

Partial Recirculation

Heat recovery for process optimization

Maximum Energy Efficiency

- Using the surplus energy from the roasting exhaust air reduces the energy consumption of the roasting process by around 40%. At the same time, CO₂ emissions are reduced.

Minimum exhaust emissions

- Returning the roasting exhaust air to the roasting process reduces the exhaust emissions that need to be treated by 70%.

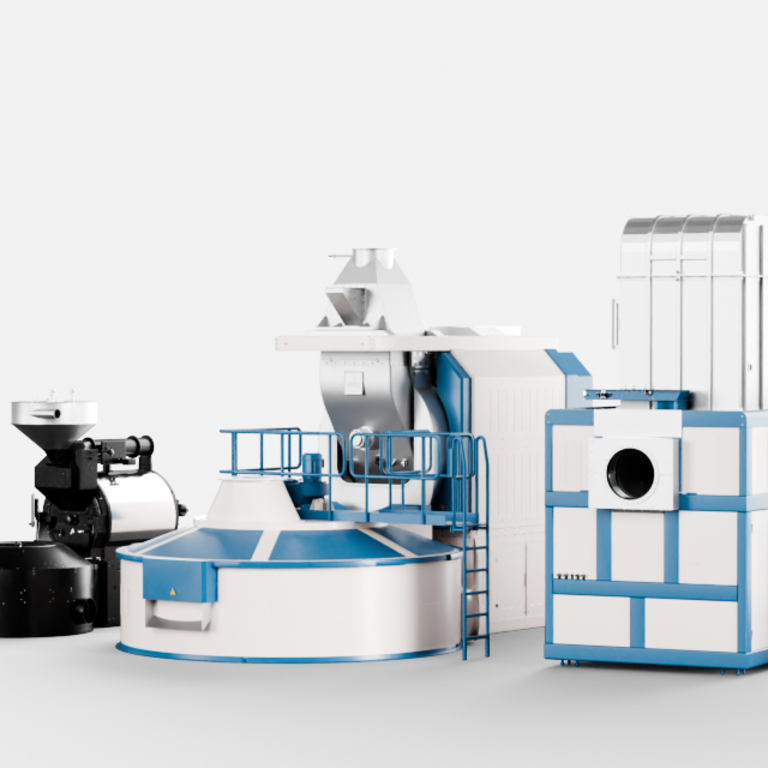

Built to solve. Designed to deliver.

With PROBAT’s partial recirculation technology, excess heat from the roasting exhaust air is intelligently recovered and fed back into the roasting process — achieving energy savings of up to 40% compared to conventional, non-recirculating systems.

Typically, at the end of the roasting cycle, the exhaust air is released through a chimney, resulting in the loss of valuable heat energy. Partial recirculation changes that by redirecting a portion of the cleaned exhaust air directly back into the roasting process via the burner, immediately after the cyclone. This innovative approach not only reduces exhaust emissions by around 70%, but also significantly lowers the energy needed for roasting.

Because PROBAT roasting systems operate the roasting process and exhaust air purification independently, they allow for maximum heat recovery and energy efficiency — unlocking savings of up to 40% for your operation.

-

Neptune with standard recirculation