QCHOC

Mixer/Refiner for recipe development and quality management in chocolate processing

Built to solve. Designed to deliver.

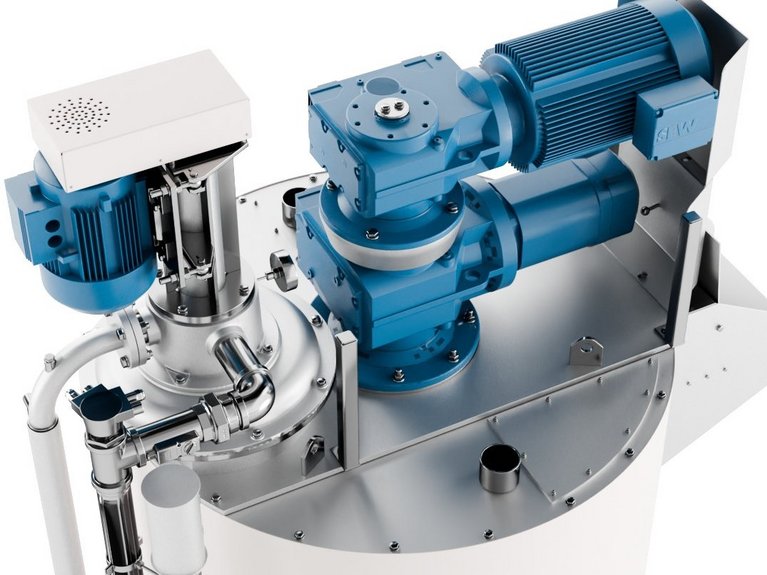

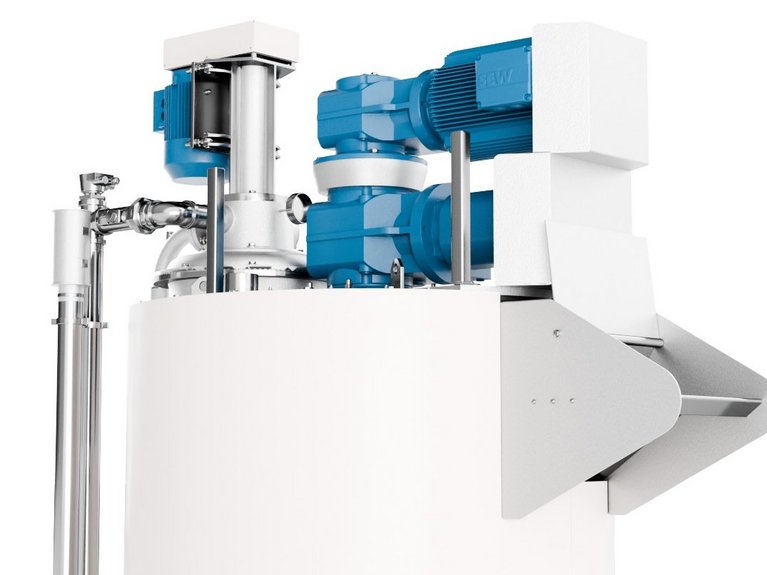

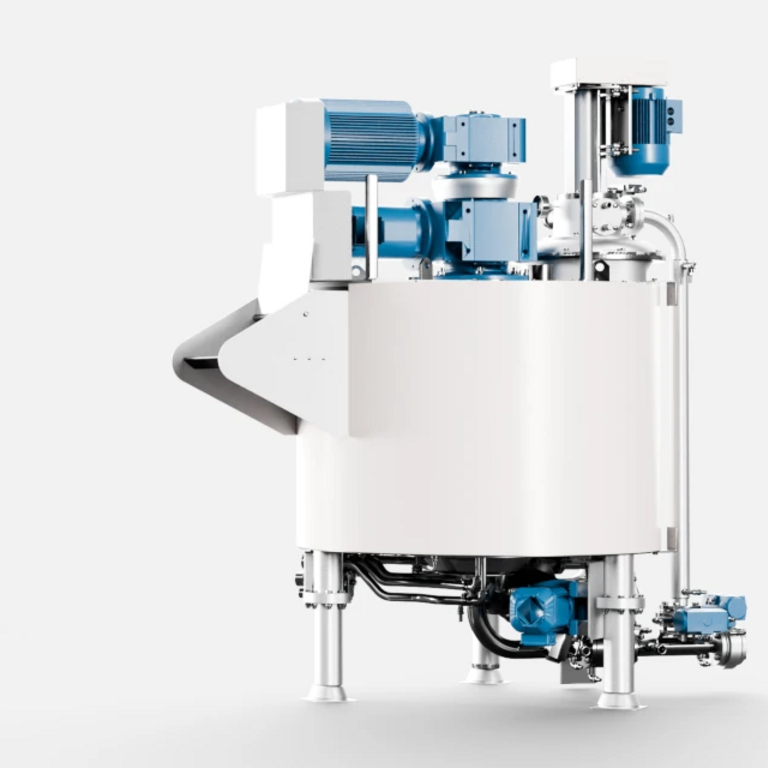

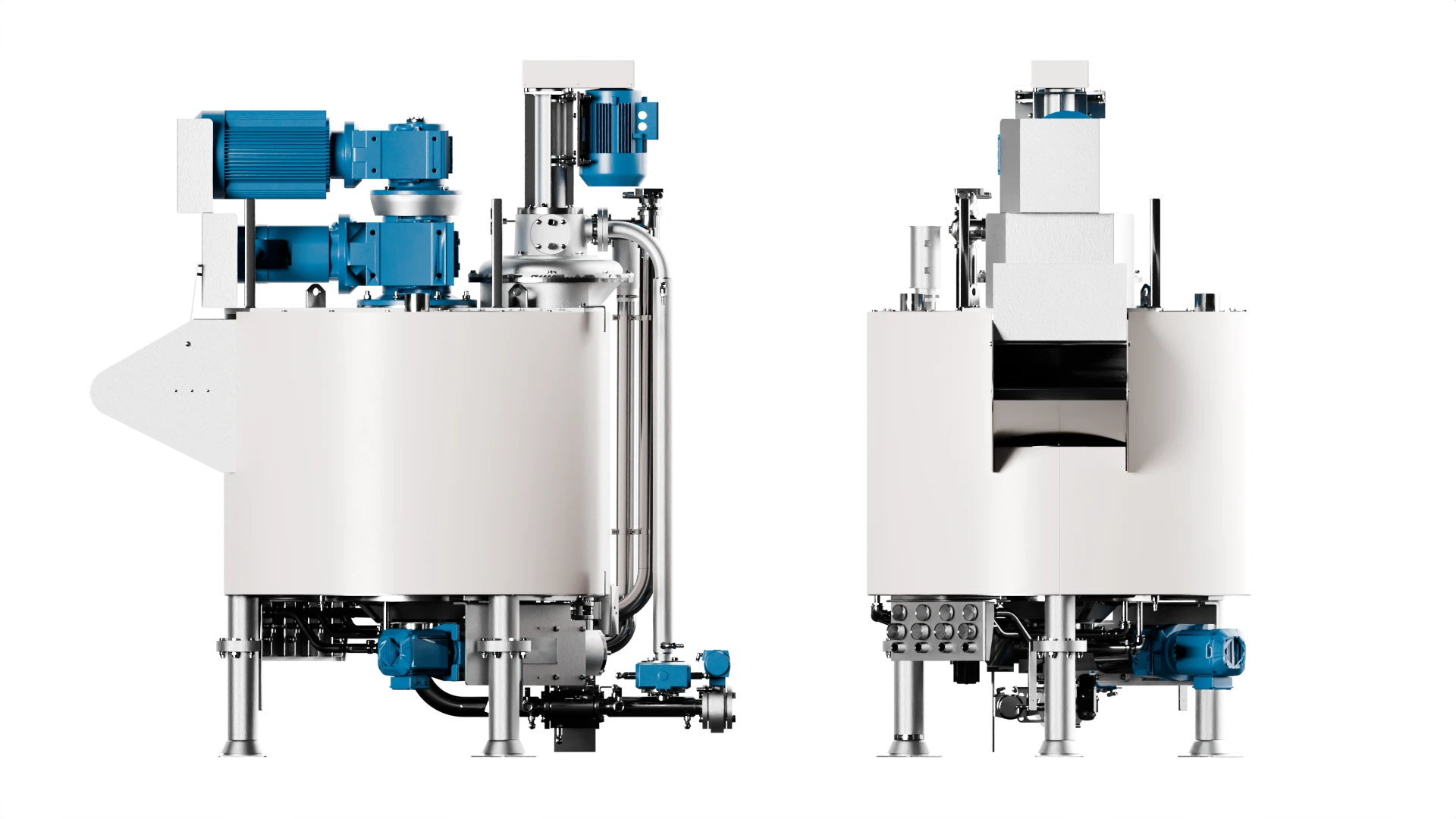

The Duyvis QCHOC 50 all-in-one chocolate system offers a smart, streamlined solution for batch-based chocolate mixing and refining – all in a single, integrated machine. Combining a pre-mixer and ball mill, it delivers exceptional efficiency, optimum particle size distribution and consistently high product quality. Designed specifically for laboratory environments, it is ideal for recipe development, quality control and small-scale production trials.

After pre-mixing, the ingredients are transferred to the ball mill where a rotating shaft with agitator arms refines the product inside a vertical, jacketed grinding tank filled with hardened steel balls. As the product circulates from bottom to top, friction between the continuously moving balls breaks down the solids to produce a fine and uniform particle size.

VERSIONS

| Duyvis QCHOC 50 | |

|---|---|

| Batch size [kg] | 50 |

| Capacity [kg/h] | 10–20 |

| Connected load [kW] | 8.5 |