WIECON

Mixer/Grinder for processing compound coatings, spreads & fillings

Built to solve. Designed to deliver.

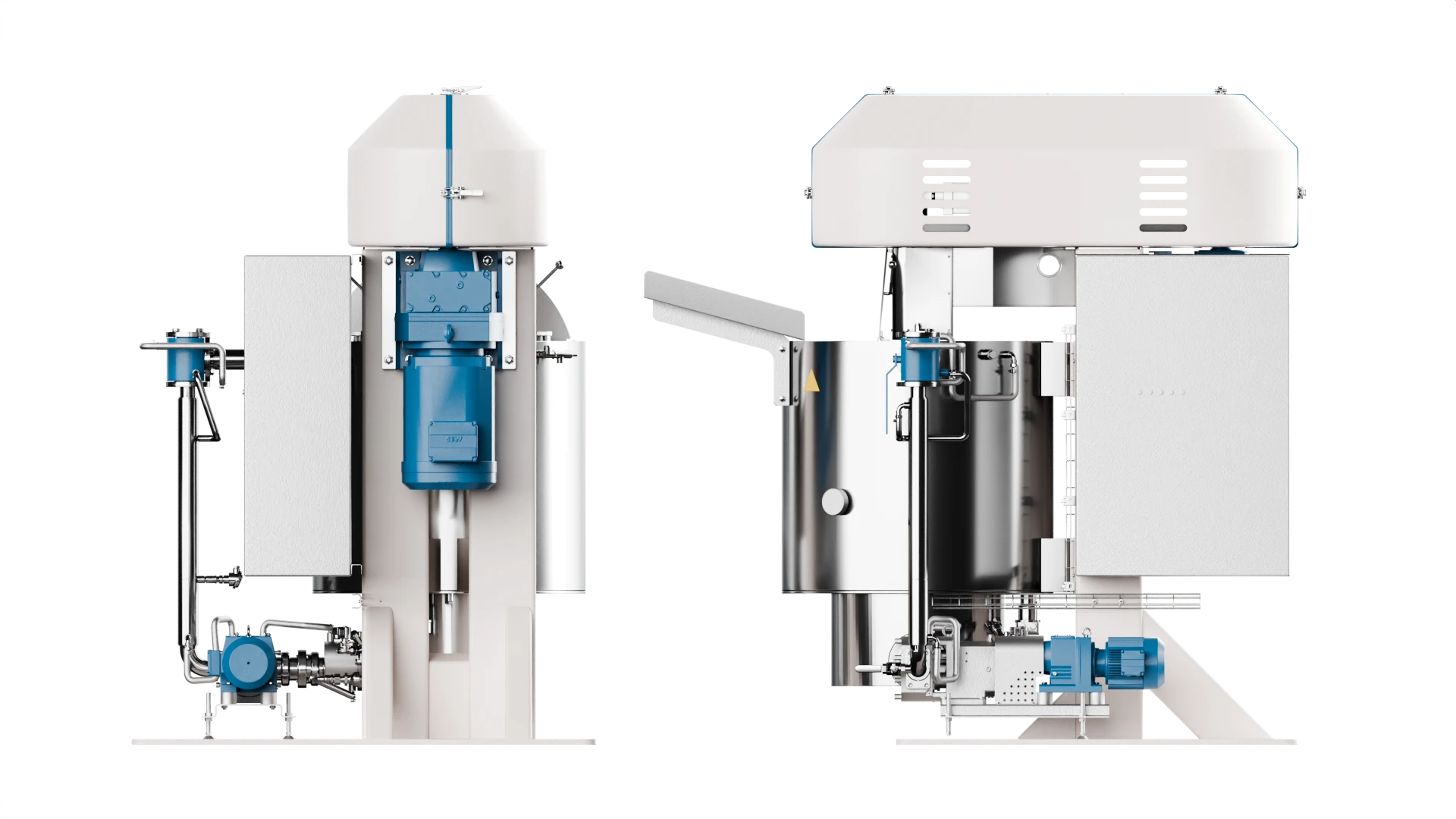

The Duyvis WIECON 50's compound system offers an advanced, all-in-one solution for the batch production of compound coatings, spreads, and fillings. Its integrated mixing and grinding vessel is expertly engineered to carry out two critical processes simultaneously: the initial blending of ingredients and the refinement of the mixture to achieve the desired final fineness.

The Wiecon 50's stirring and grinding chamber features a double-walled, energy-efficient design, partitioned into two sections for optimized performance. The integrated recirculation system, driven by a dedicated pump, continuously circulates the mixture from the bottom of the vessel, through the recirculation tube, and back to the top throughout the process. Once the desired particle size is achieved, the entire batch is pumped back into the main vessel and discharged via the recirculation system.

VERSIONS

| Duyvis WIECON 50 | |

|---|---|

| Capacity [kg/batch dark chocolate 20–25 µm] | –175 |

| Connected load [kW] | 25 |