BCD Batch Conche Double

Batch conche for chocolate processing

Built to solve. Designed to deliver.

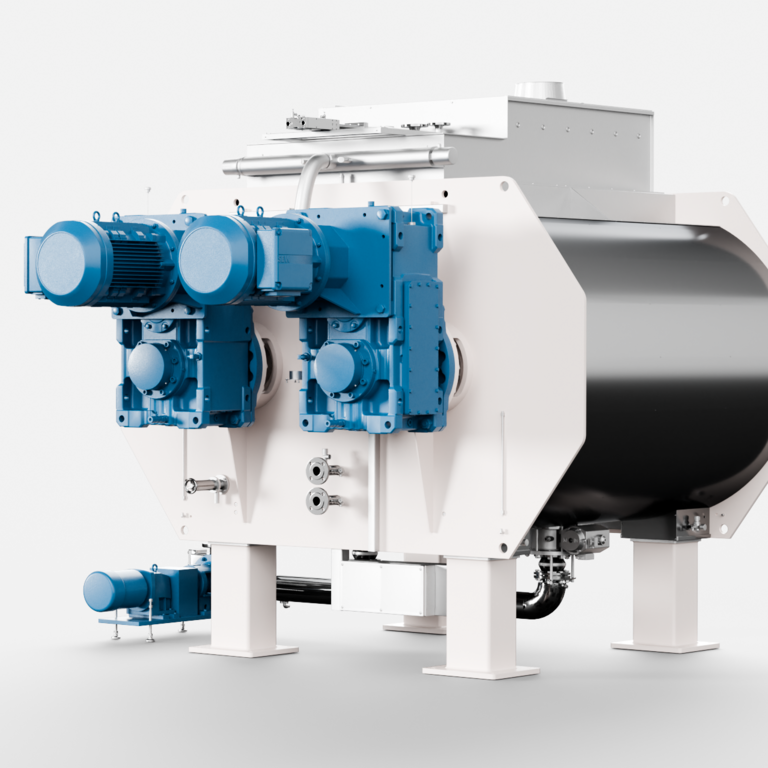

The Heidenauer BCD Batch Conche Double is designed to improve refined chocolate flakes by reducing the natural moisture content of ingredients such as cocoa mass. At the same time, it eliminates undesirable flavors that may be present in the mass. The BCD can be loaded directly with refined dry chocolate powder – without the need to add cocoa butter, fat or lecithin.

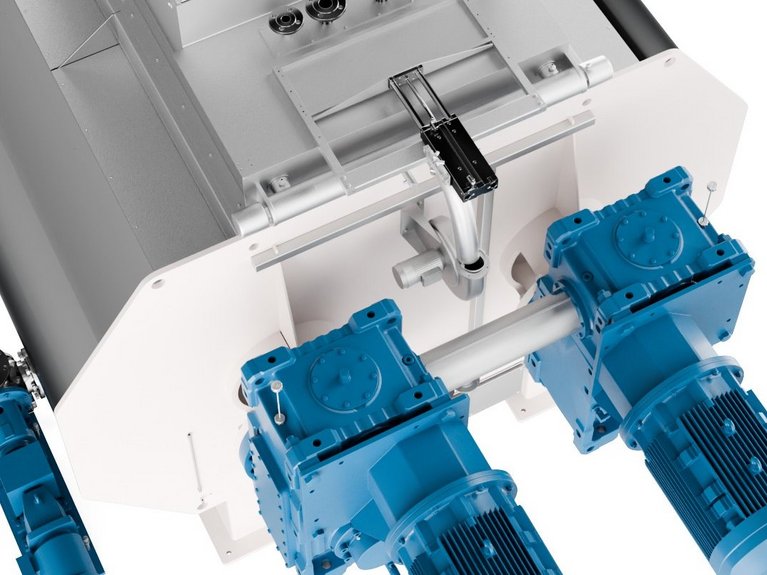

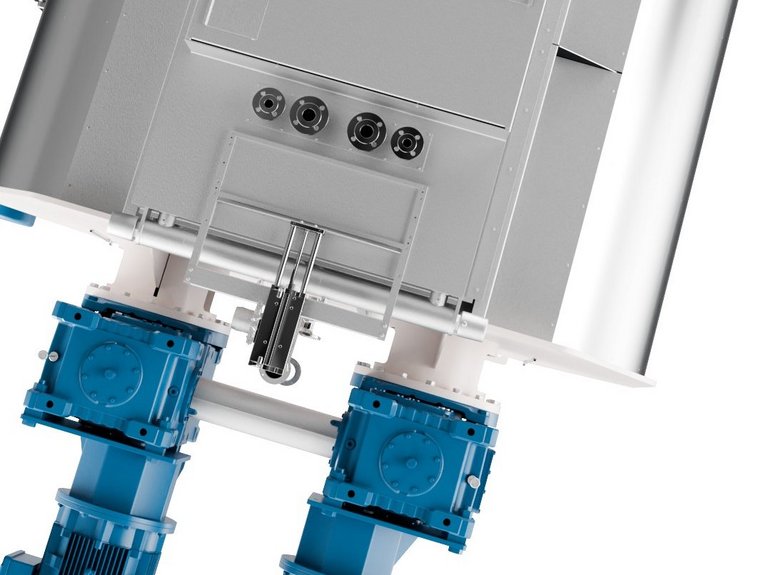

The BCD's shaft uses an agitator arm to scrape the batch surface, ensuring even chocolate distribution and applying targeted shear stress to increase viscosity. This mechanical action releases fat and promotes uniform cocoa butter coverage on the sugar crystals – developing a rich, well-rounded flavor without the need for added cocoa butter, fats or lecithin.

Designed for exceptional conching efficiency, the BCD excels in low fat formulations, with overlapping conching zones providing intensive shear and kneading forces for rapid rheology development. Advanced process control allows flexible operation, offering both passive and active aeration within the conching chamber. Flavor complexity is further improved by Maillard reaction enhancement, driven by precisely managed conche headspace via the Flavor Monitoring Cockpit and integrated air conditioning.

VERSIONS

| Heidenauer BCD 3000 | Heidenauer BCD 6000 | |

|---|---|---|

| Capacity [kg/batch] | 3,000 | 6,000 |

| Capacity [kg/h] | 375 | 720 |

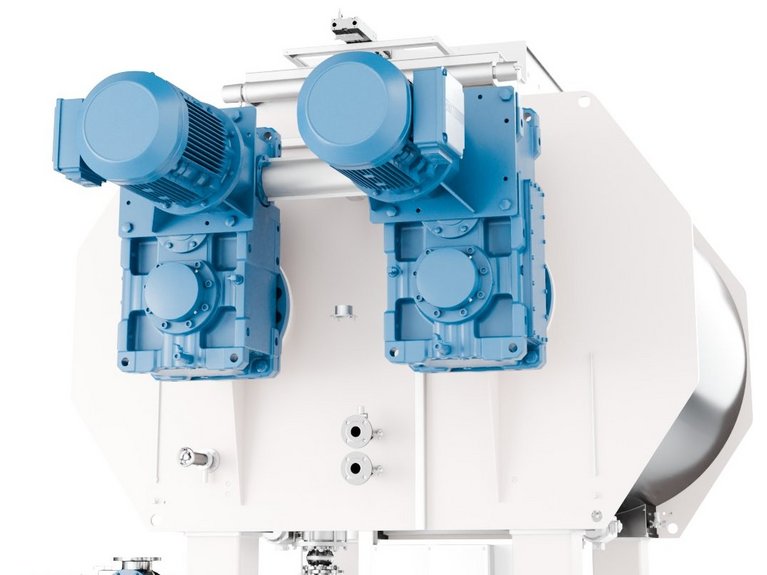

| Connected Load [kW] | 2 x 45 main drives | 2 x 75 main drives |