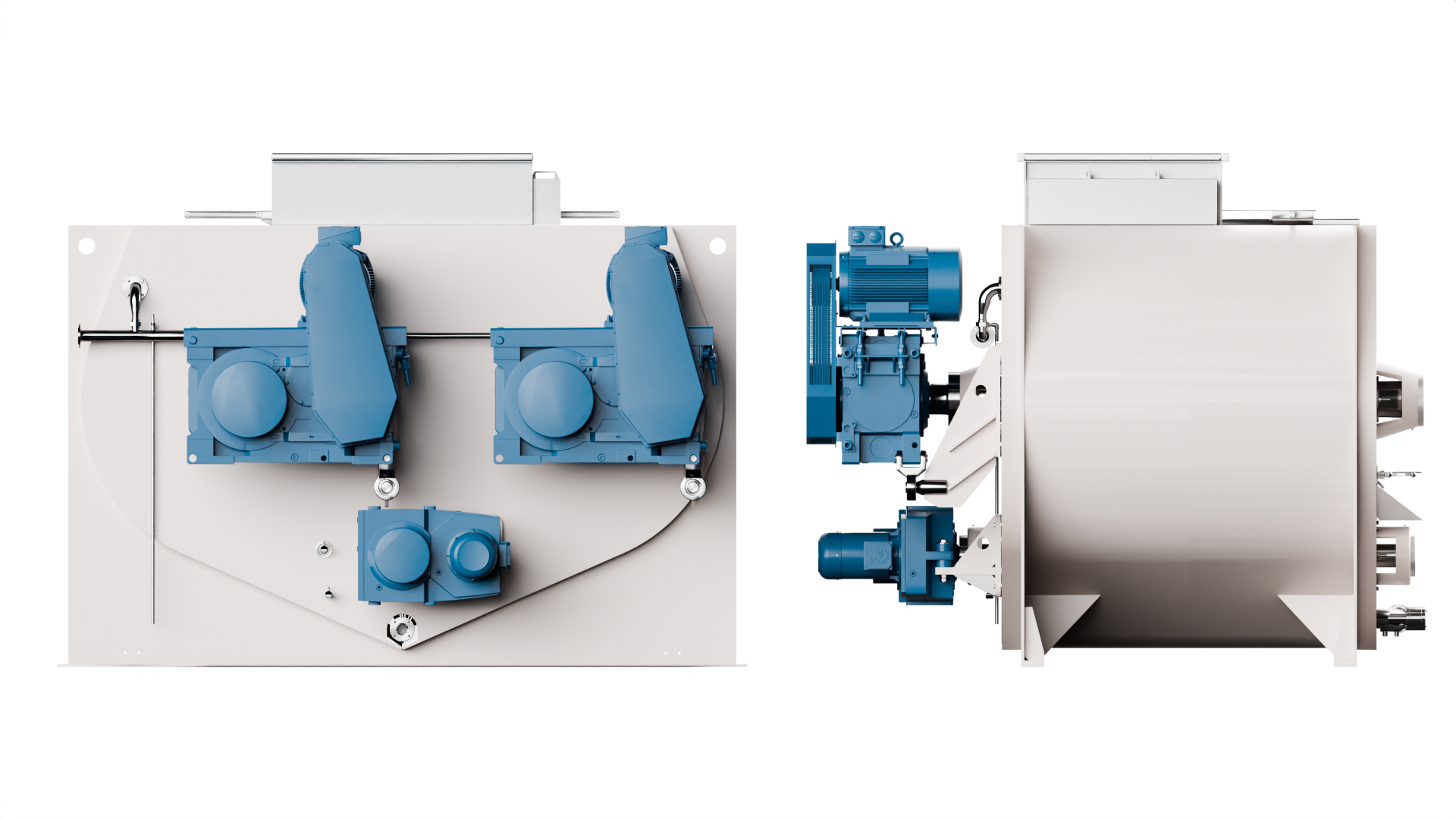

BCT Batch Conche Triple

Batch conche for chocolate processing

Built to solve. Designed to deliver.

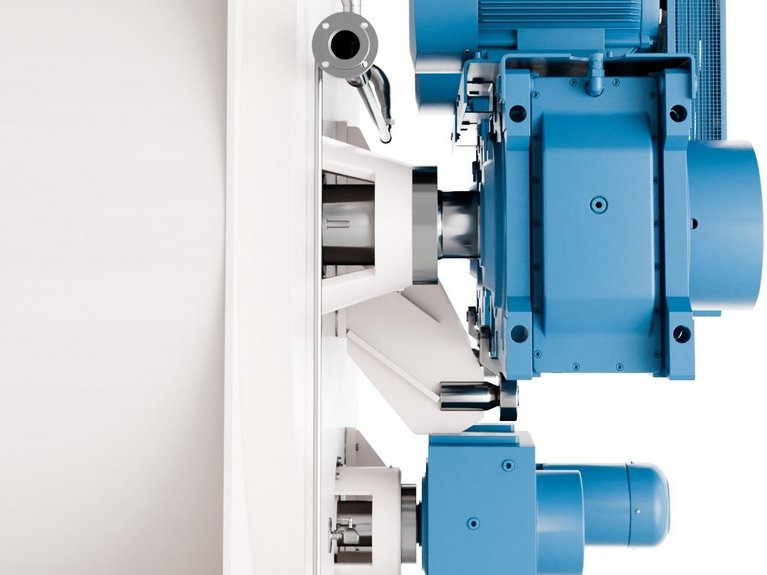

The Thouet BCT Batch Conche Triple is designed to improve refined chocolate flakes by reducing the natural moisture content of ingredients such as cocoa mass. At the same time, it eliminates undesirable flavors that may be present in the mass. The BCT can be loaded directly with refined dry chocolate powder - without the need to add cocoa butter, fat or lecithin.

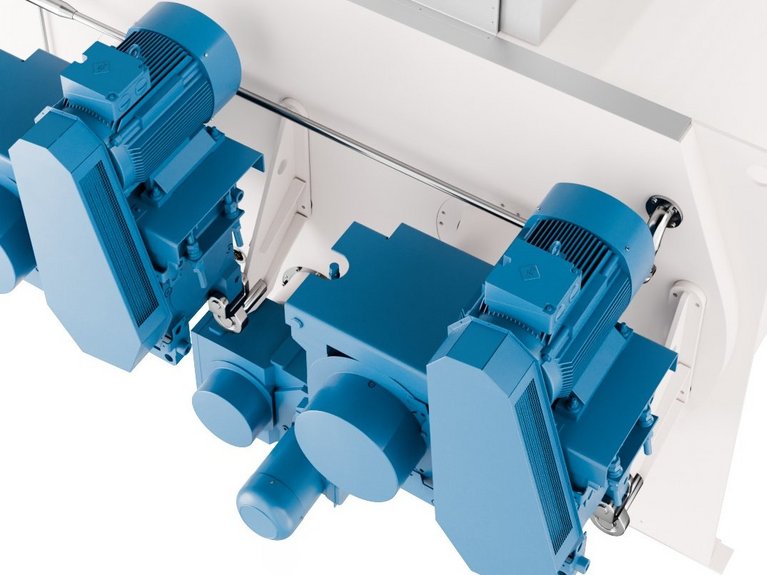

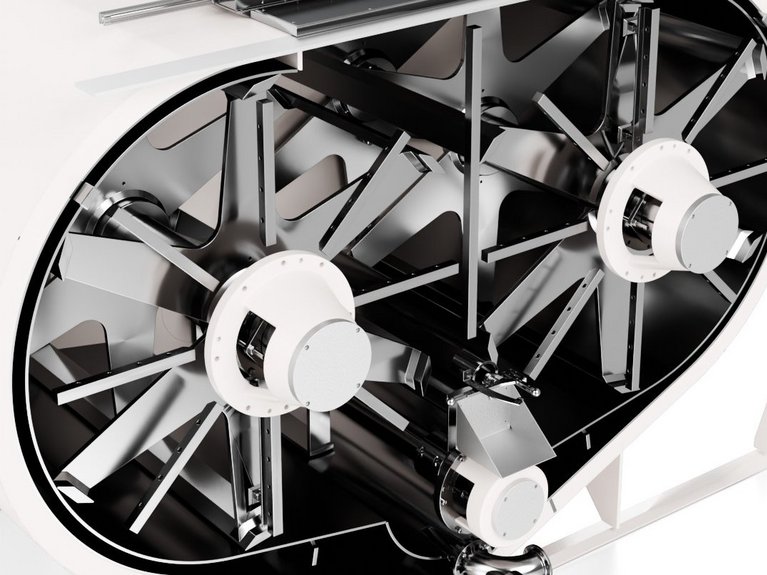

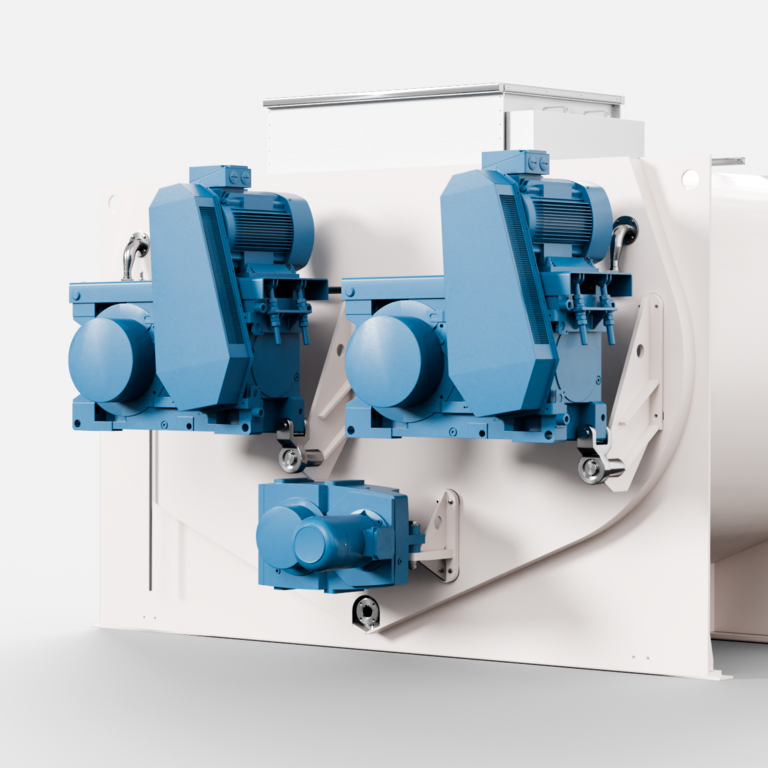

The three conching shafts have six precisely spaced conching elements that generate optimum shear forces. As the dry flakes rotate, they interact intensively with the agitator, air and the main ingredients - sugar, cocoa solids, cocoa butter and milk powder. This mechanical and thermal processing releases cocoa butter, coating particles for a smooth texture, while eliminating off-flavors and allowing chemical transformations, including enhanced Maillard reactions. The result is a homogeneous liquid chocolate with ideal flow properties and a refined flavor, which is further optimized by controlled conche headspace through the Flavor Monitoring Cockpit and air conditioning.

VERSIONS

| Thouet BCT 4000 | Thouet BCT 6000 | Thouet BCT 9000 | |

|---|---|---|---|

| Capacity [kg/batch] | 4,000 | 6,000 | 9,000 |

| Capacity [kg/h] | 333 | 633 | 1,000 |

| Connected Load [kW] | 100 | 161 | 195 |