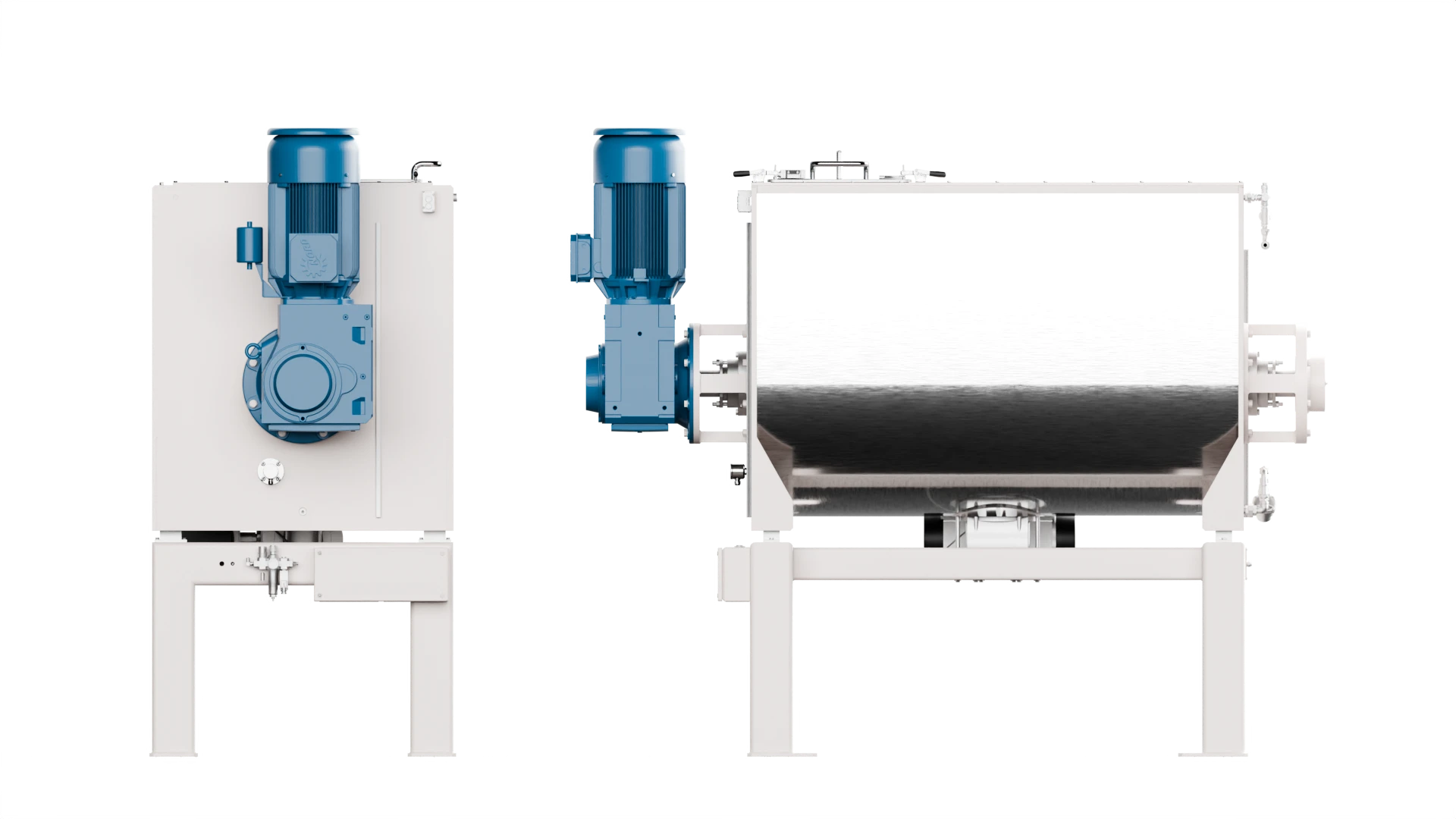

BLS Batch Liquefier Single

Batch Liquefier for processing fillings, coatings and spreads

Built to solve. Designed to deliver.

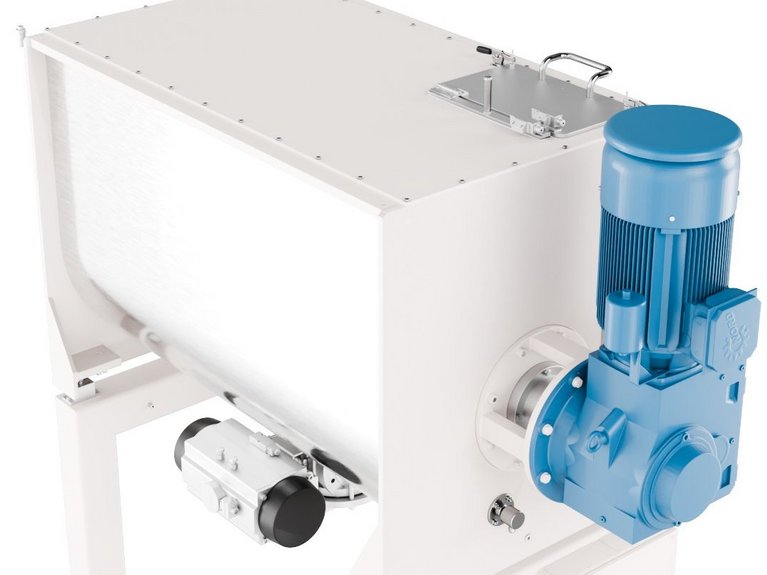

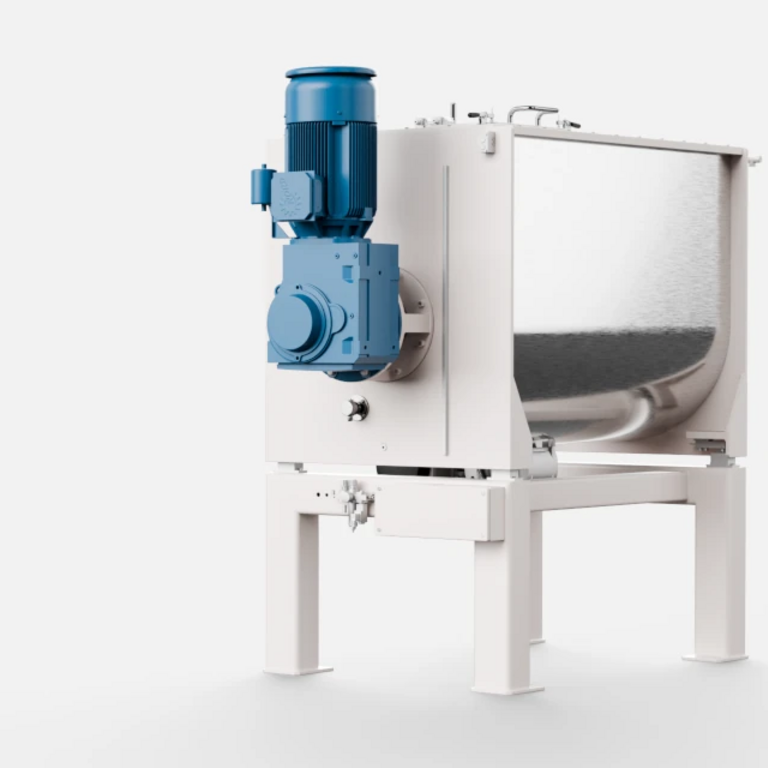

The Heidenauer BLS Batch Liquefier Single is designed for fast and efficient liquefaction of finely rolled fillings, coatings and spreads containing vegetable fats and cocoa butter. It features a horizontal shaft design with a double-jacketed heating system to ensure fast, uniform mixing for superior product consistency.

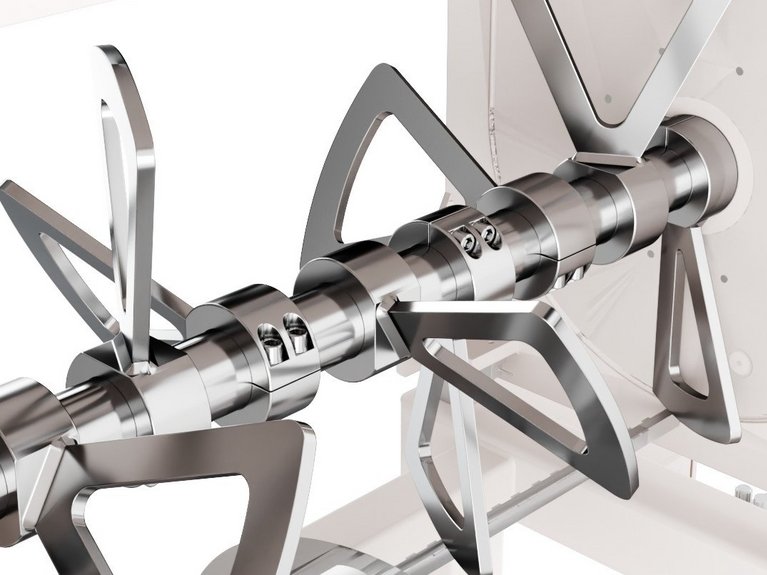

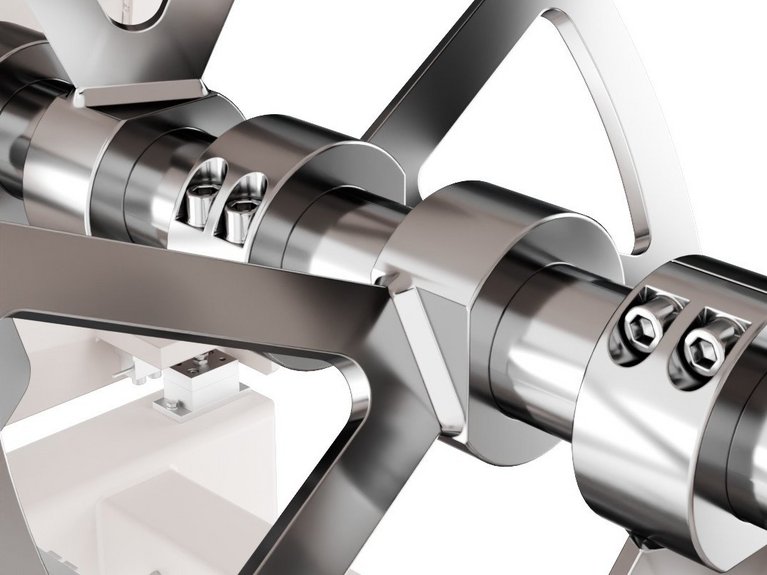

The horizontal shaft, with a specially aligned mixing element, directs the product to the trough's center. The frequency-controlled main drive ensures fast, efficient homogenization and optimal plasticity. Internal scrapers and ball valves minimize product residue, while automatic recipe management guarantees maximum reliability.

The BLS is designed to fit seamlessly into a production line following a GM Gap Mill and CL Air Classifier for precision dry processing, but is also an integral part of the classic chocolate line following the FRF Fine Refiner.

VERSIONS

| Heidenauer BLS 1000 | Heidenauer BLS 2000 | |

|---|---|---|

| Batch Size [kg] | 1,000 | 2,000 |

| Throughput [kg/h] | 1,000–3,000 | 3,000–6,000 |

| Connected Load [kW] | 22.5 | 37.5 |