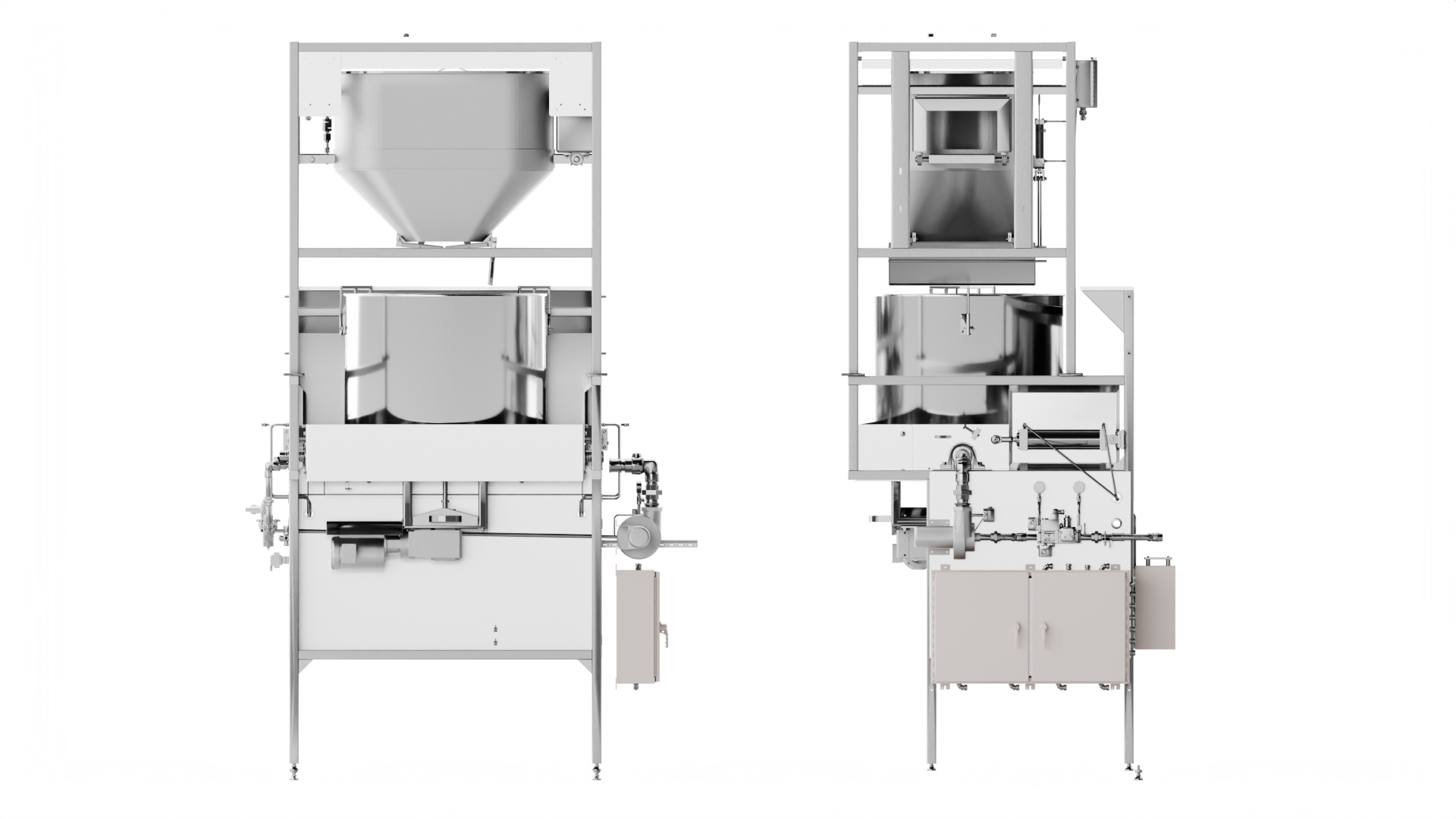

M205 Cooker/Coater Series

Production of caramel corn

Built to solve. Designed to deliver.

The Horn M205 Popcorn Cooker/Coater is a high-performance, high-volume batch coating system designed to produce perfect caramel corn every time, all within a single machine. It is trusted by industry leaders around the globe and is the preferred choice for snack food producers seeking exceptional quality and efficiency.

Designed as part of a modular, scalable solution, the M205 can easily adapt to growing production demands. Additional components such as the Continuous Dry Popper, the M319 Slurry Pump System for preparing pre-coating slurry and the M416 Rotary Cooler can be seamlessly integrated as production requirements evolve, enabling capacities of up to 450 kg/h and fully automating your production line.

Before the popcorn is added, a precise mixture of slurry is expertly blended and heated within the M205’s drum. Once the pre-programmed temperature is reached, pre-popped corn is introduced into the mixture. The variable-speed agitator then gently and evenly folds the popped corn into the caramel syrup, ensuring each kernel is perfectly coated. Once the caramelized popcorn is fully prepared, it is transferred onto a cooling table for efficient separation and cooling.

Versions

| Horn M205-S | Horn M205-D | |

|---|---|---|

| Capacity [kg/h] | 227 | 450 |