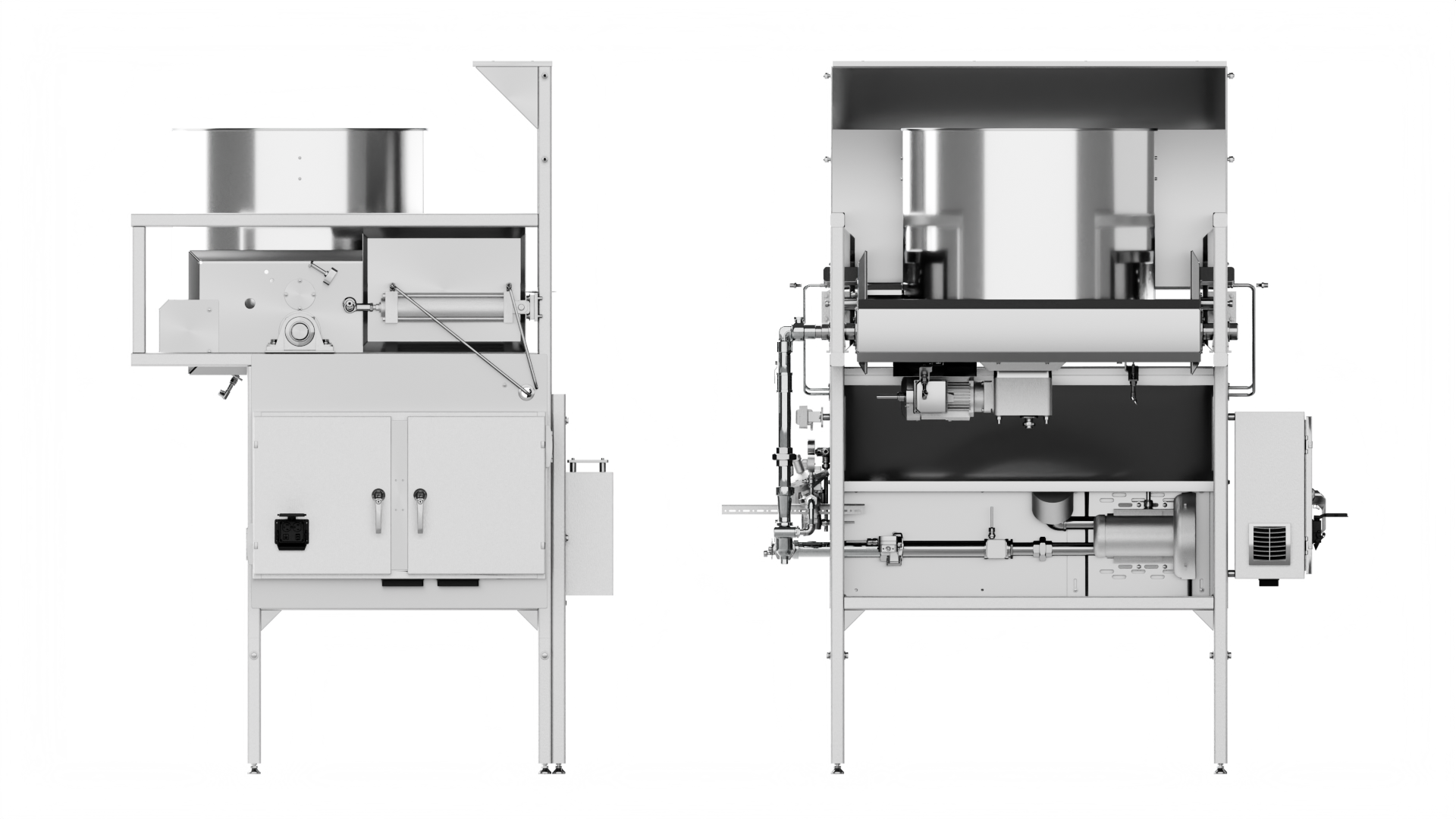

M360 Cooker/Coater Series

Production of popcorn

Built to solve. Designed to deliver.

The Horn M360 Popcorn Cooker/Coater is a high-performance, high-volume batch coating system engineered to produce premium caramelized popcorn with exceptional efficiency. Designed as part of a modular and scalable solution, the M360 adapts seamlessly to growing production demands. As your production needs expand, additional components, such as the Continuous Dry Popper, the M319 Slurry Pump System for pre-coating slurry preparation, and the M416 Rotary Cooler, can be integrated to semi-automate the line, enabling production capacities of up to 300 kg/h.

Before the popcorn is added, a precise mixture of slurry is blended and heated inside the drum of the M360. Once the pre-programmed temperature is reached, pre-popped corn is added to the mixture. The variable-speed agitator then carefully folds the popped corn into the caramel syrup, ensuring that each kernel is evenly coated. Once the caramelized popcorn is ready, it is transferred to a cooling table to separate and cool it efficiently, ready for the next step in the production process.

Versions

| Horn M360-S | Horn M360-D | |

|---|---|---|

| Capacity [kg/h] | 150 | 300 |