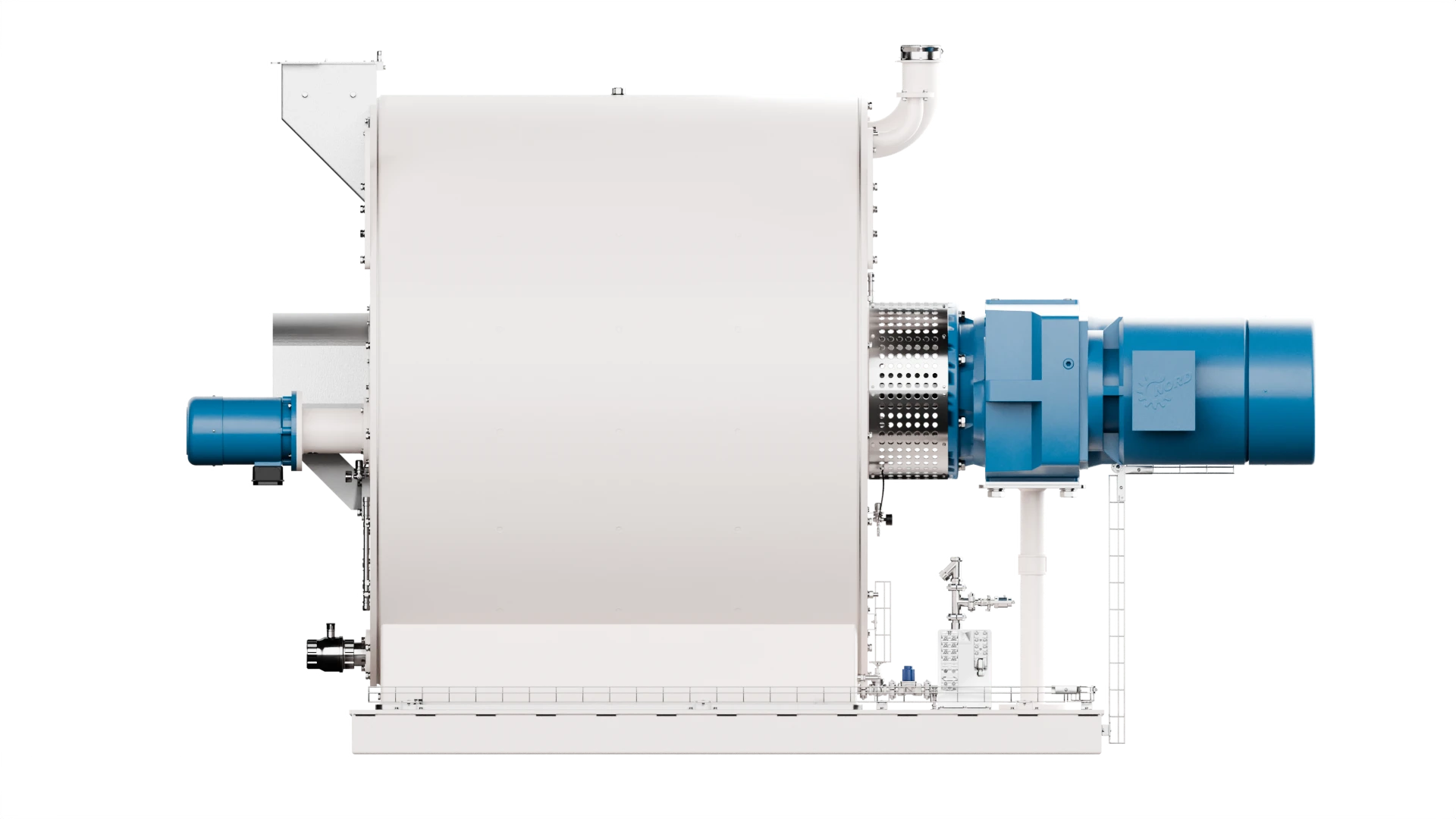

RC Refiner/Conche

Refiner/Conche for processing chocolate, compounds, coatings, fillings, pralines and truffles

Built to solve. Designed to deliver.

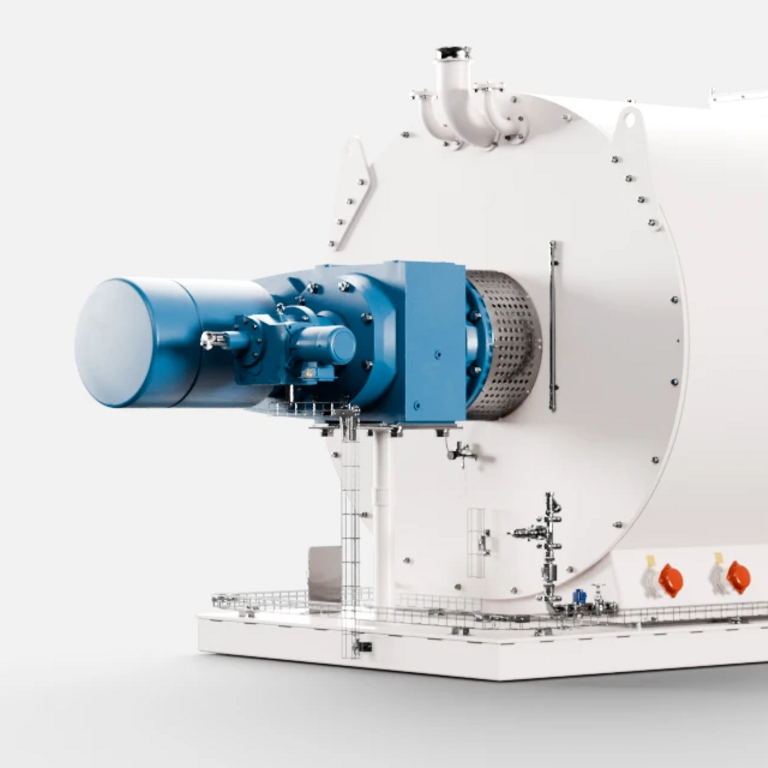

The MACINTYRE Refiner/Conche is an innovative, all-in-one solution that seamlessly integrates five key processes: cocoa nib grinding, pasteurizing, sugar grinding, mixing, refining, and conching – within a single, compact machine. Designed for flexibility and efficiency, it serves as a universal tool for the production of chocolate, compounds, coatings, pralines, truffles, and fillings, making it ideal for small to medium-scale manufacturing. Additionally, the MACINTYRE Refiner/Conche excels at processing a wide range of rework, further enhancing its versatility and value.

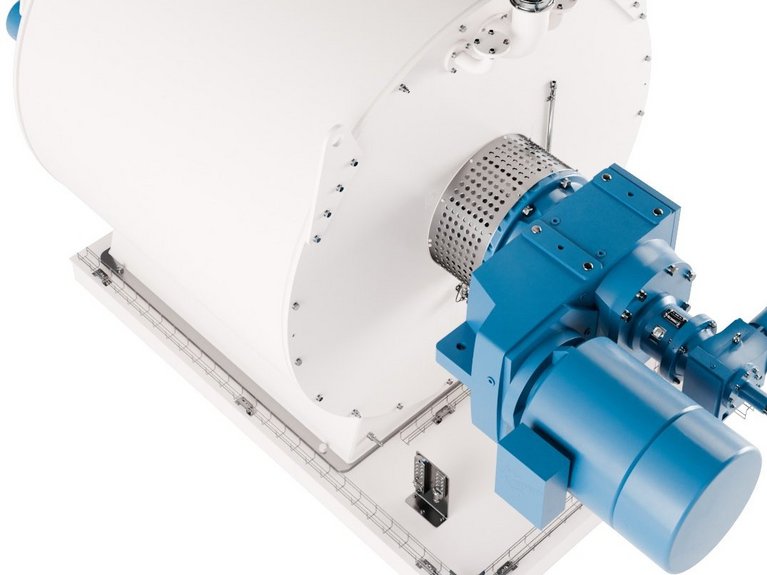

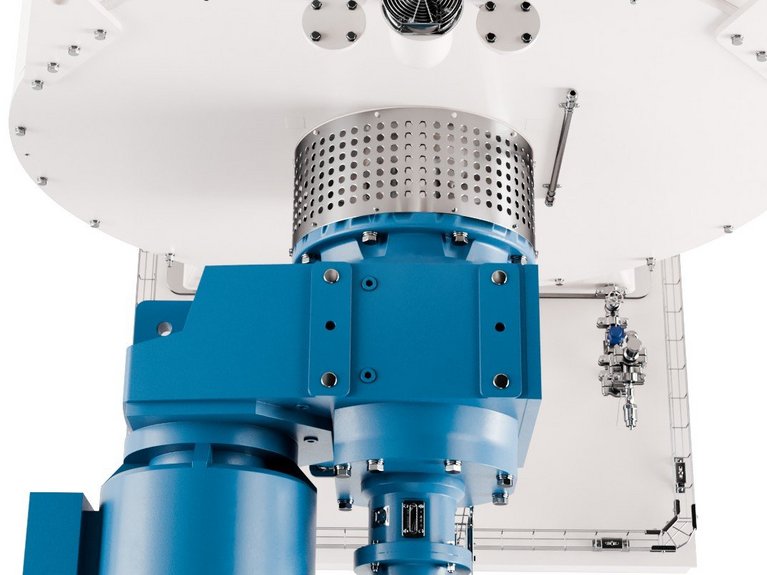

The Refiner/Conche features a specially engineered shaft with grinding bars and an adjustable pressure mechanism, allowing precise control over the product between the grinding and lining bars. This ensures a stable process and consistent product quality across batches

This all-in-one machine supports a flexible, step-by-step workflow:

- Cocoa nib grinding – with optional pasteurization via water addition, heating, and rotation

- Mixing – rotor rotation without applied pressure

- Refining – rotor rotation with pressure on the grinding bars

- Conching – rotor rotation with low or no pressure for smooth texture development

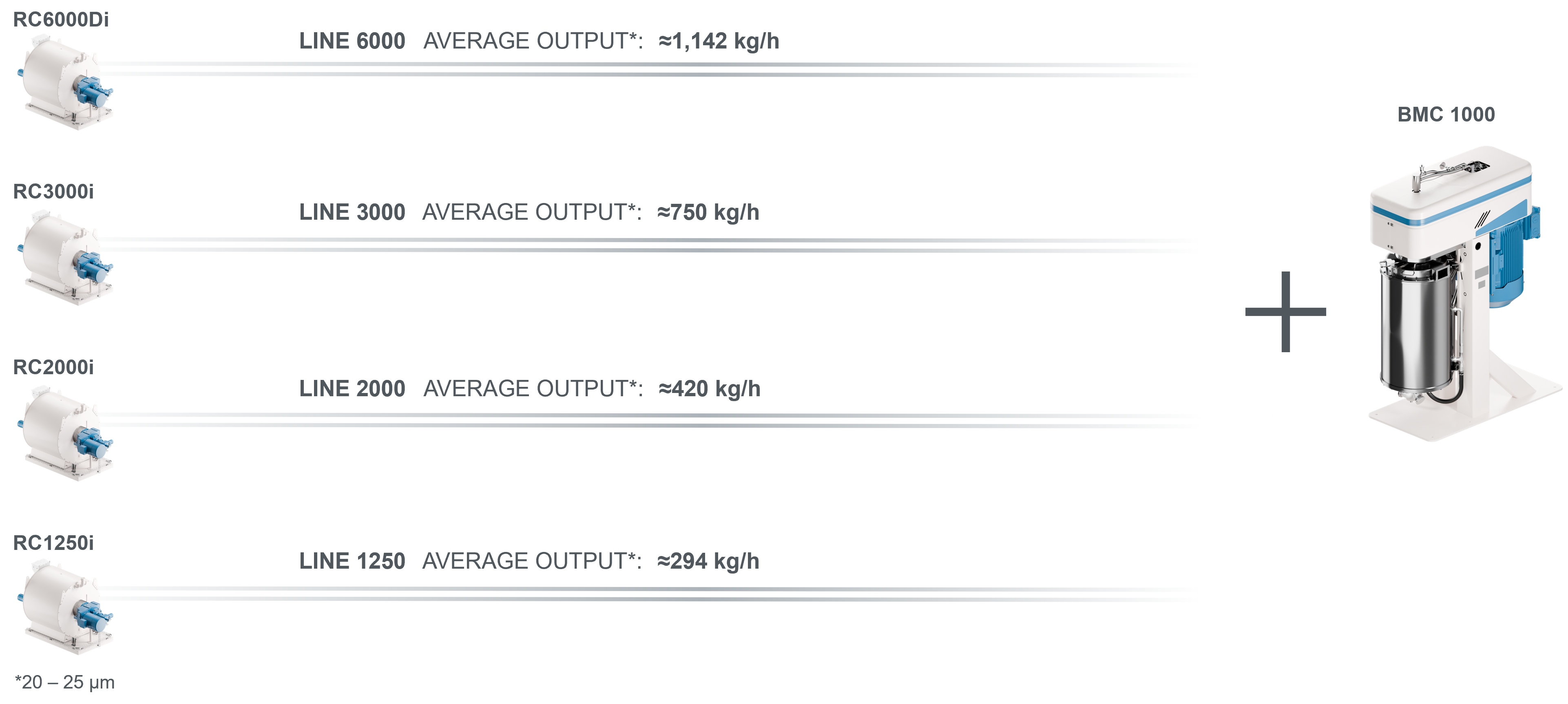

The Refiner/Conche functions as a stand-alone unit but is also engineered for seamless integration into a production line upstream of the BMC ball mill as an integral part of the MACINTYRE/WIENER Line. By combining mixing and pre-grinding in the Refiner/Conche with final fine grinding in the BMC, overall processing times are significantly reduced.

VERSIONS

| MACINTYRE RC 45 | MACINTYRE RC 500 | MACINTYRE RC 1250 | MACINTYRE RC 2000 | MACINTYRE RC 3000 Di | MACINTYRE RC 5000 Di | MACINTYRE RC 6000 Di | |

|---|---|---|---|---|---|---|---|

| Batch Size [kg] | 45 | 500 | 1,250 | 2,000 | 3,000 | 5,000 | 6,000 |

| Capacity [kg/h] | 9 | 83 | 147 | 235 | 330/333 | 555 | 571 |

| Connected Load [kW] | 1,5 | 18,5 | 22 | 37 | 55 | 75 | 75 |

MACINTYRE/WIENER LINE