CCD Continuous Conditioner Drum

Pre-Treatment of raw cocoa beans for nib processing

Built to solve. Designed to deliver.

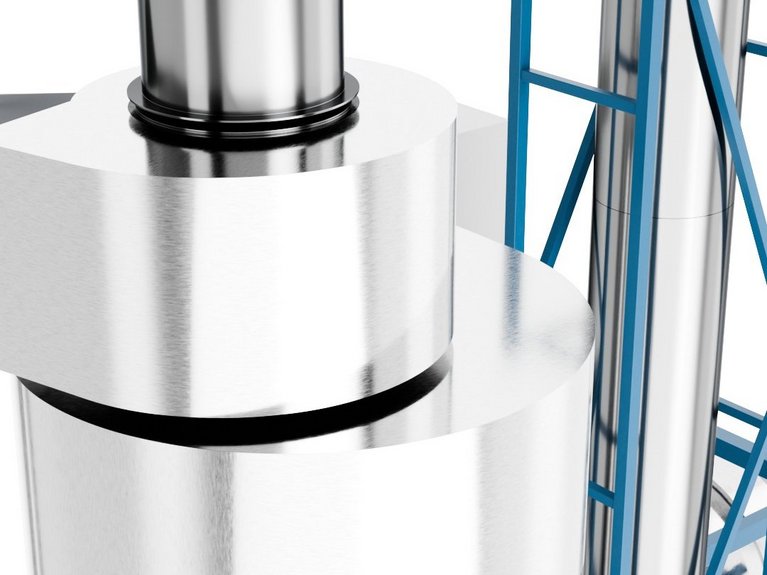

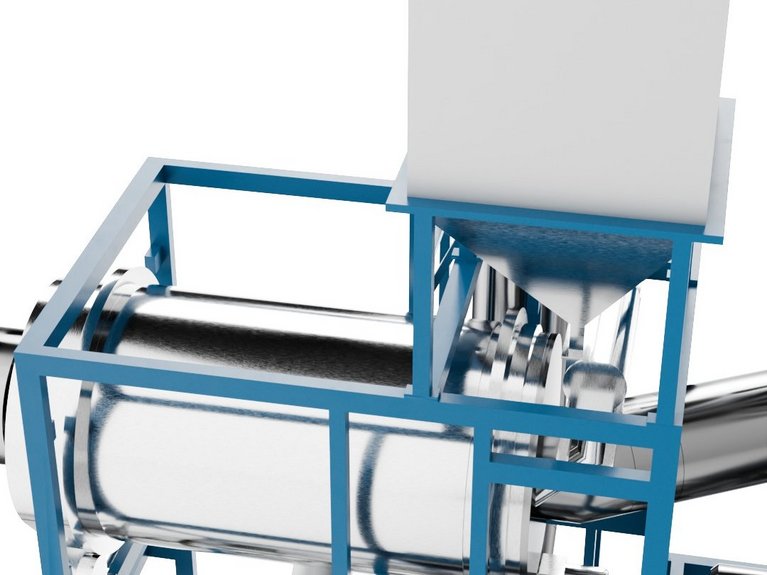

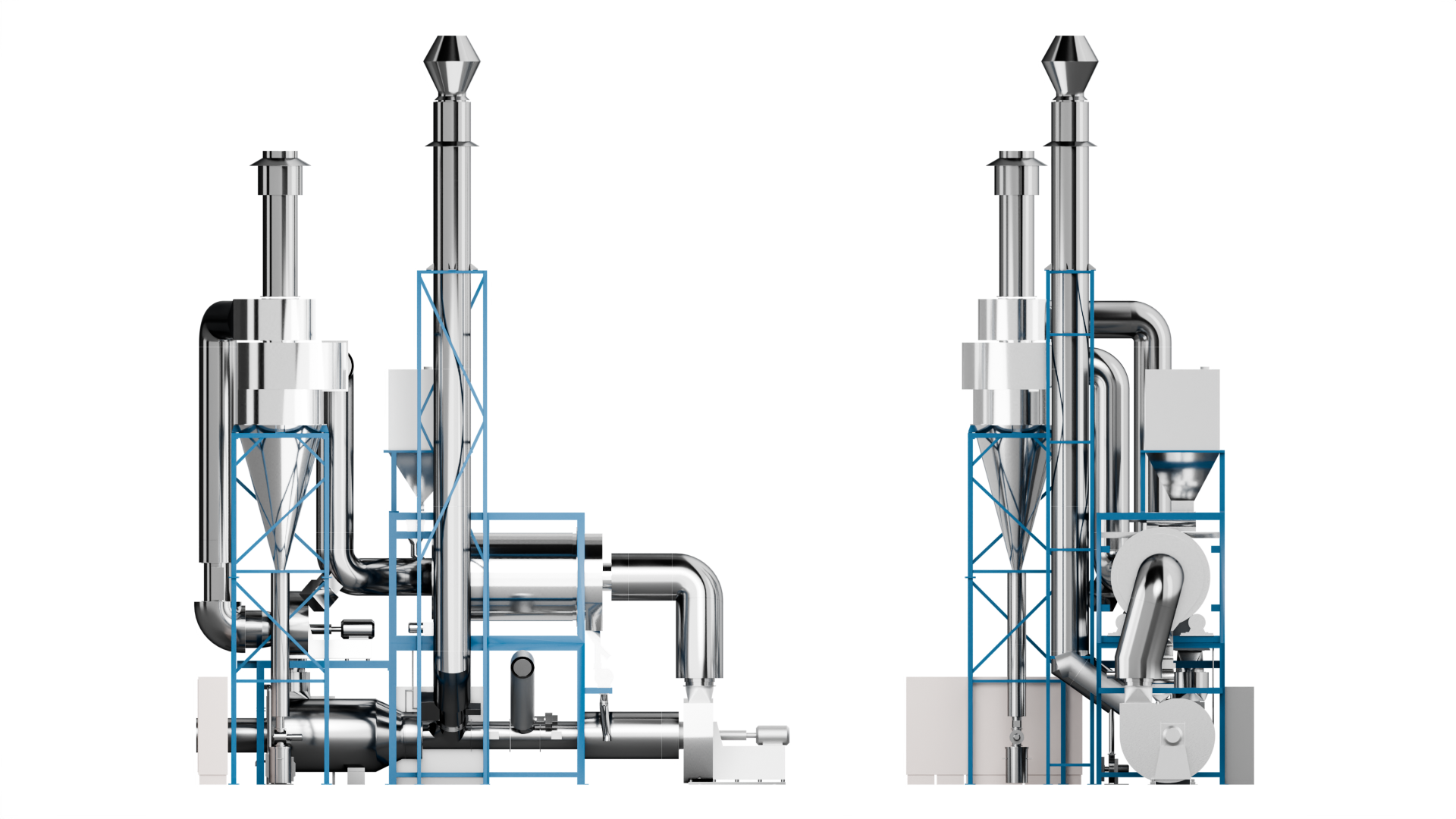

The PROBAT CCD Continuous Conditioner Drum is specifically designed to pre-treat flat, shrunken and poorly fermented lower quality cocoa beans to ensure optimum breaking in subsequent processing stages. By applying high thermal energy over a short period of time (90–120 seconds), the system reduces the adhesion between the shell and the nib through expansion, completely loosening the bulky shell. The shell volume is increased by up to 20%, while the number of plates is significantly reduced. This process effectively replaces traditional infrared (IR) treatment, eliminating the need for costly IR element replacement.

To promote greater shell expansion relative to the pulp – effectively 'popping' the shells – a precisely controlled amount of water is sprayed onto the surface of the beans inside the drum of the CCD. This is followed by a rapid and intense application of heat, which causes the moisture in the shell to evaporate instantly and expand outwards, increasing its volume. The short processing time minimizes unwanted drying, preserves moisture content and maximizes yield for downstream processing. At the same time, the rotating drum and turbulent airflow ensure uniform treatment of each bean, while integrated heat recovery systems help to reduce overall energy consumption.

Versions

| PROBAT CCD 3000 | PROBAT CCD 6000 | PROBAT CCD 9000 | |

|---|---|---|---|

| Throughput [kg/h] | 3,000 | 6,000 | 9,000 |

| kW (el) | 44 | 91 | 110 |

| kW (burner) | 450 | 900 | 1,350 |