CCL Continuous Conditioner Louver / BDB Batch DeBacterizer

Pre-Treatment of raw cocoa beans for nib processing

Built to solve. Designed to deliver.

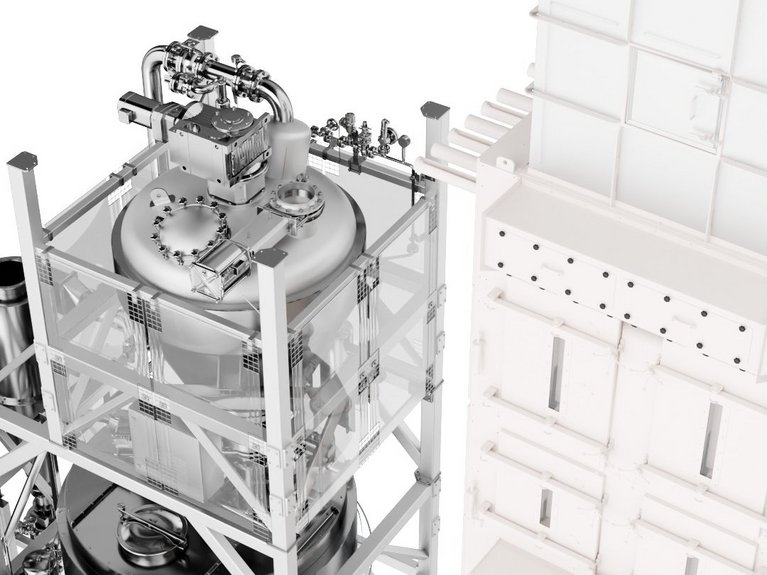

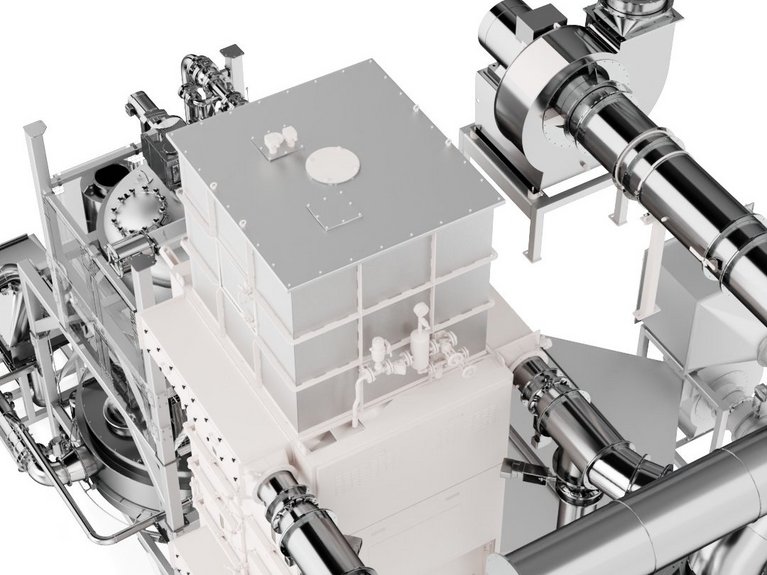

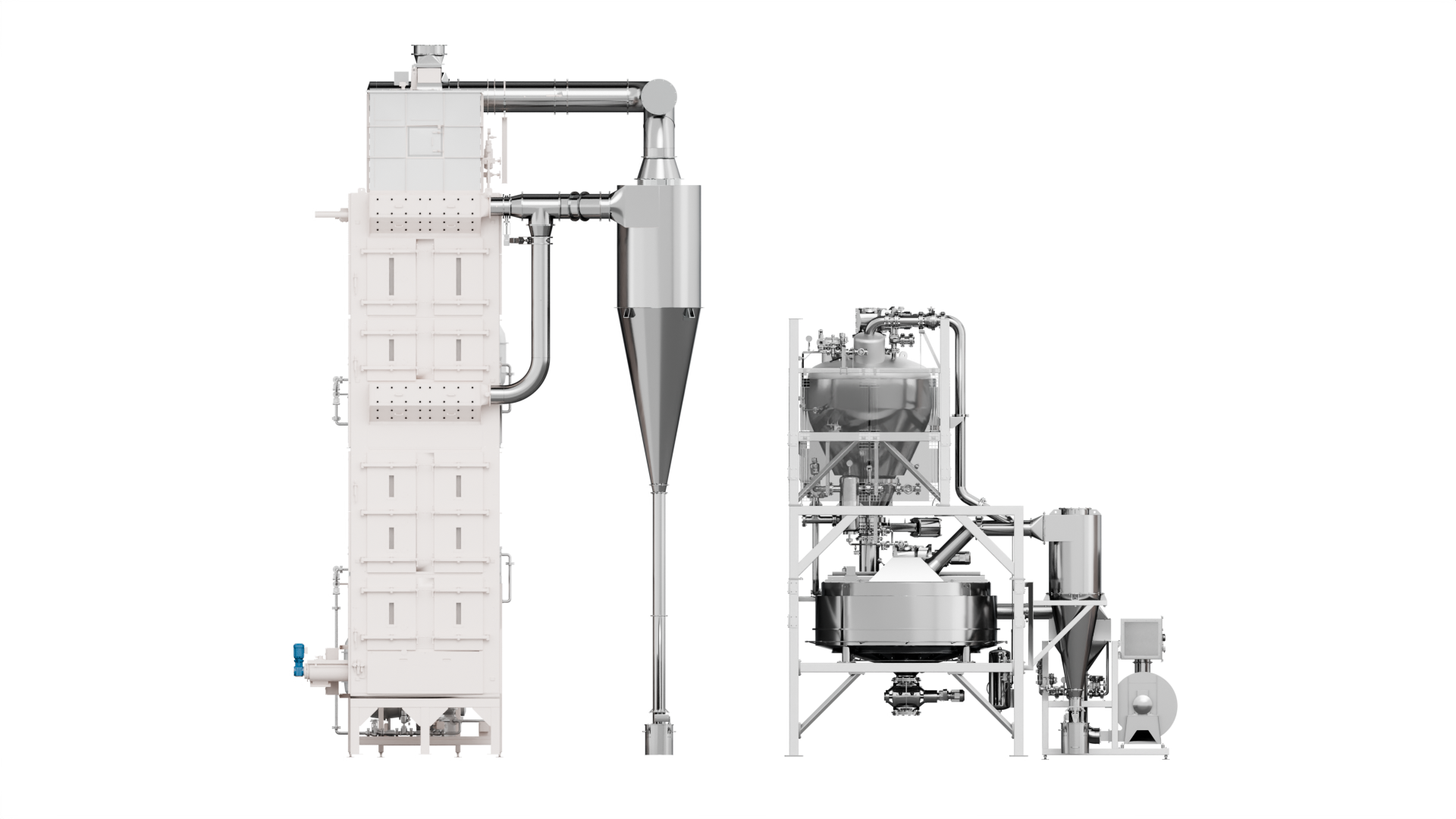

The Lehmann CCL Continuous Conditioner Louver is specifically designed for the initial pre-treatment of raw cocoa beans to effectively remove the cocoa from the shell – a key step known as "popping". This process ensures efficient shell-nib separation while minimizing yield loss prior to nib roasting. The downstream Lehmann BDB Batch Debacterizer further enhances shell separation through targeted steam treatment, significantly improving overall process efficiency.

The CCL operates on the counter-current hot air principle, where cocoa beans are fed in at the top and gently descend through multiple levels. Simultaneously, hot air flows upwards, efficiently transferring heat to the beans while removing moisture. A slight vacuum is maintained in the chamber to optimize moisture removal throughout the drying process.

The carefully controlled interplay of steam, heat and time inside the BDB intensifies the popping effect and ensures efficient separation of the shell from the nibs.

Versions

| Lehmann CCL/BDB 5800 | Lehmann CCL/BDB 8000 | |

|---|---|---|

| Capacity [kg/h] | 4,200–5,800 | 5,800–8,000 |

| Steam requirement [kg/h] | 1,350–1,500 | 1,200–1,600 |

| Connected load [kW] | 86 | 117 |