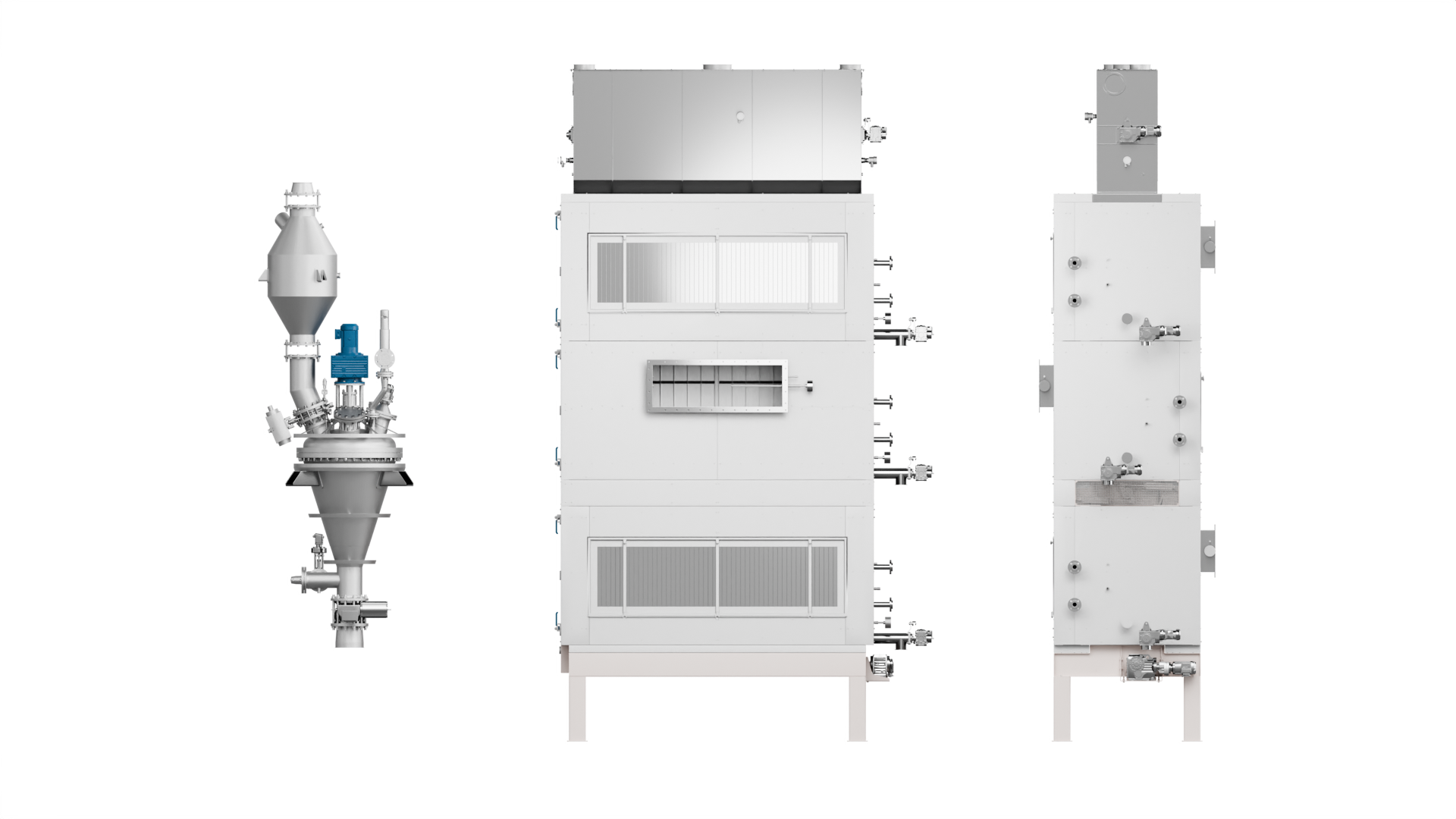

MDB Microbatch DeBacterizer / CCS Continuous Conditioner Shaft

Pre-Treatment of raw cocoa beans for nib processing

Built to solve. Designed to deliver.

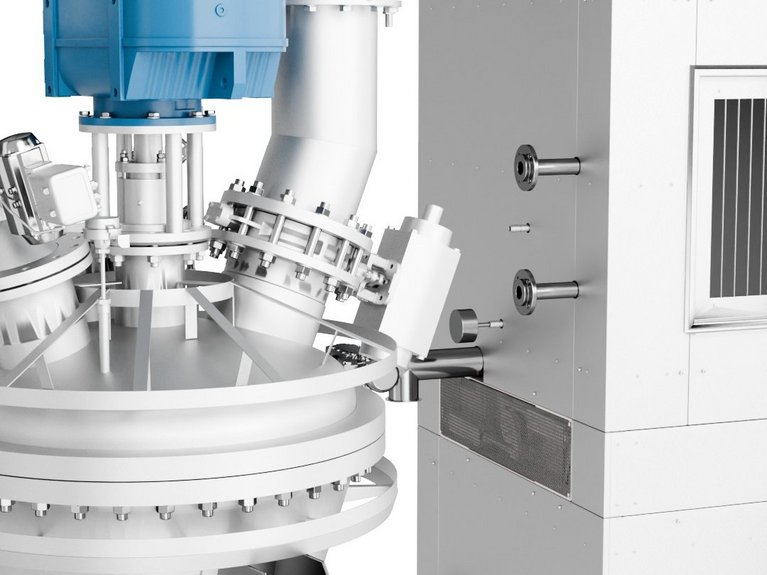

The PROBAT CCS Continuous Conditioner Shaft is specifically designed for the initial pre-treatment of raw cocoa beans, focusing on removing the pulp from the shell – a critical step known as "popping". This process allows optimal separation of the shell and nibs, significantly reducing yield losses prior to nib roasting. The PROBAT MDB Microbatch DeBacterizer, installed upstream, initiates this separation through targeted steam treatment. The MDB is essential to ensure that shell/nib separation meets regulatory quality standards.

In the CCS, cocoa beans are gently conveyed from top to bottom through several processing stages. Maintaining product temperatures below 80°C preserves flavor integrity and creates optimal conditions for downstream roasting. Precise moisture control enhances the Maillard reaction during subsequent roasting, resulting in superior flavor development. Within the MDB, finely adjustable heat, pressure and steam settings support the popping effect and ensure efficient separation of the nibs from the kernel.

Versions

| Versions | PROBAT MDB/CCS 2000 | PROBAT MDB/CCS 4000 | PROBAT MDB/CCS 6000 | PROBAT MDB/CCS 8000 |

|---|---|---|---|---|

| Capacity [kg/h] | 2,000 | 4,000 | 6,000 | 8,000 |

| Steam requirement [kg/h] | 450–500 | 900–1,000 | 1,350–1,500 | 1,800–2,000 |

| Connected load [kW] | 23 | 45 | 67.5 | 90 |