BAN Batch Alkalizer Nibs

Alkalizing of cocoa nibs

Built to solve. Designed to deliver.

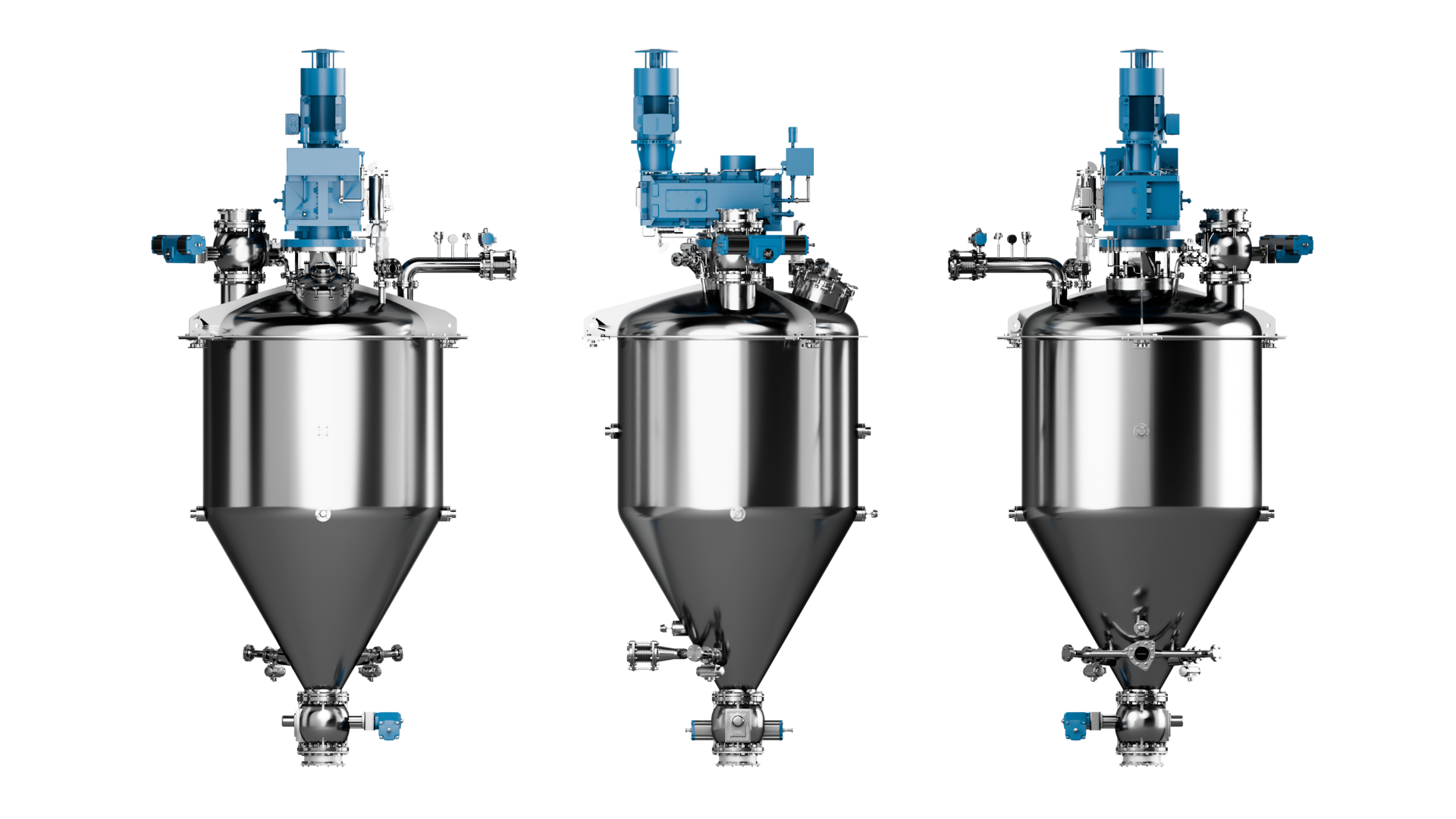

The Duyvis BAN Batch Alkalizer Nibs is specially designed to produce a wide range of colors from light to deep dark and from red to brown. The nibs are treated with a very high moisture content. By adding up to 35% of an alkaline solution, pH values of up to 8.0 can be achieved with corresponding changes in color (CIE*L*a*b value) and flavor.

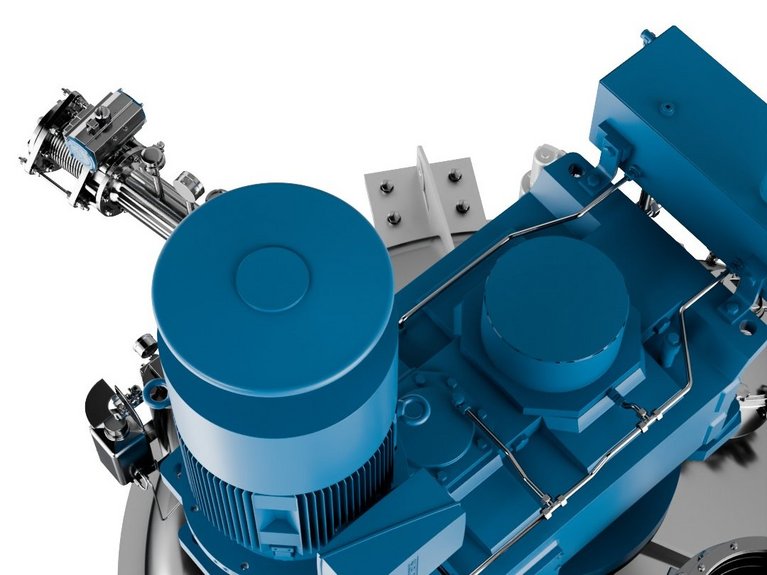

Prior to roasting, an alkalizing solution is added to the nibs in the BAN vessel. Designed with a wider structure and tapered screw, the vessel ensures fast, efficient mixing, resulting in uniform color development and consistent acidity reduction throughout the batch. The specially designed hot air injection system provides extended alkalization time and improved color intensity by injecting up to 5,000m³ of hot air at 150°C to accelerate drying. The BAN delivers best-in-class mixing performance with minimal mixing time. The gentle operation of its mixers also helps reduce fine particle formation and product stress.

Versions

| Versions | Duyvis BAN 3500 | Duyvis BAN 6000 |

|---|---|---|

| Batch Size [kg] | 3,500 | 6,000 |

| Capacity [kg/h] | 1,750 | 3,000 |

| Connected Load [kW] | 147 | 147 |

| Steam connection [kg/h] | 2,300 | 2,300 |

| Compressed air connection [nm3/h] | 600 | 925 |