BDB Batch DeBacterizer

Popping / Debacterization of raw cocoa beans for cocoa processing

Built to solve. Designed to deliver.

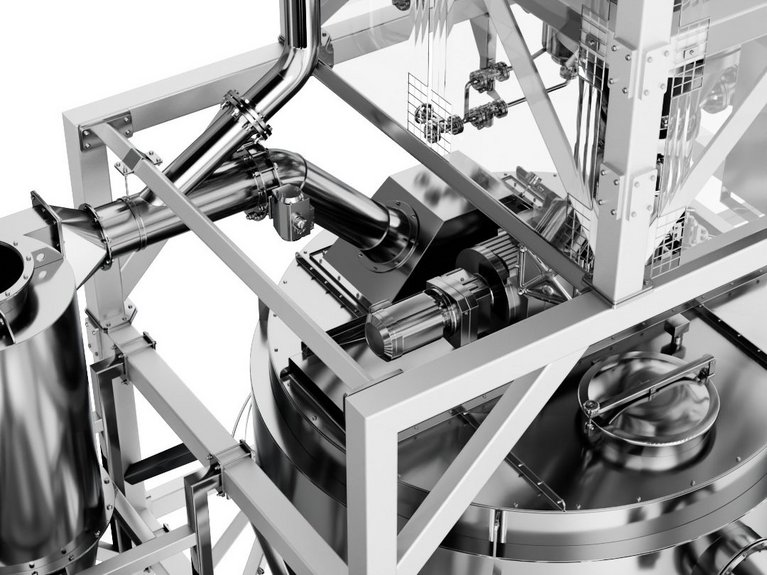

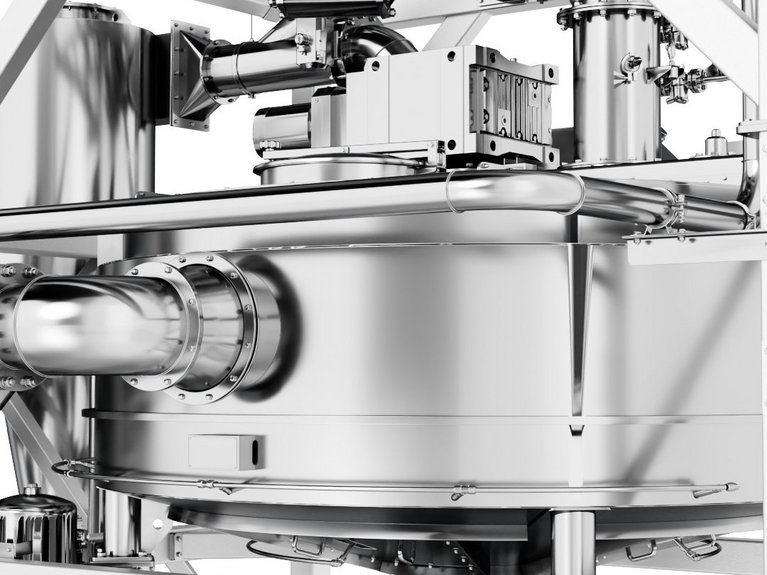

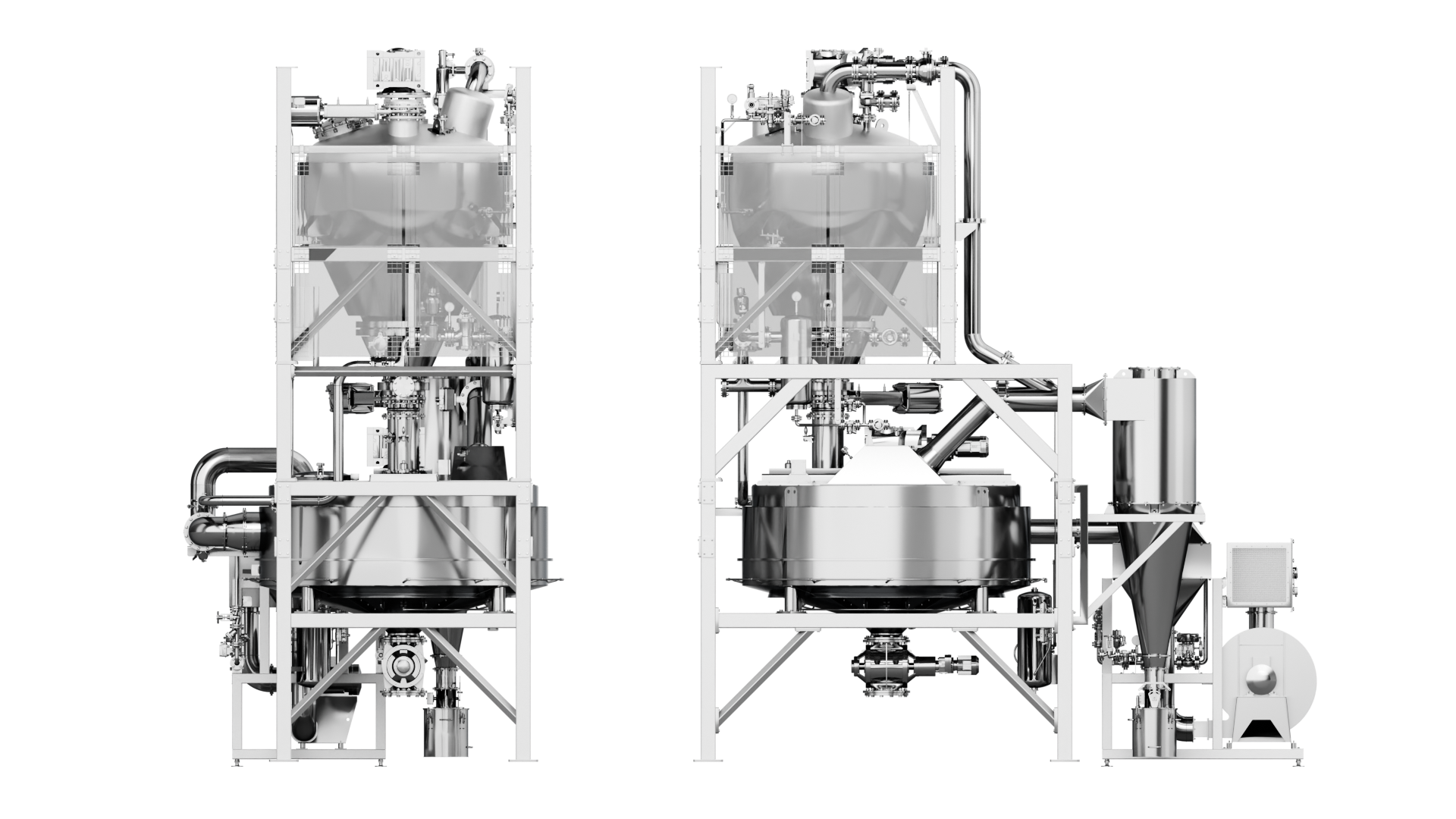

The Lehmann BDB Batch DeBacterizer is purpose-built for the pre-treatment of raw cocoa beans, using targeted steam application to initiate the critical separation of shell and nibs. This carefully controlled process minimizes yield losses and ensures compliance with stringent regulatory standards for shell/nib separation.

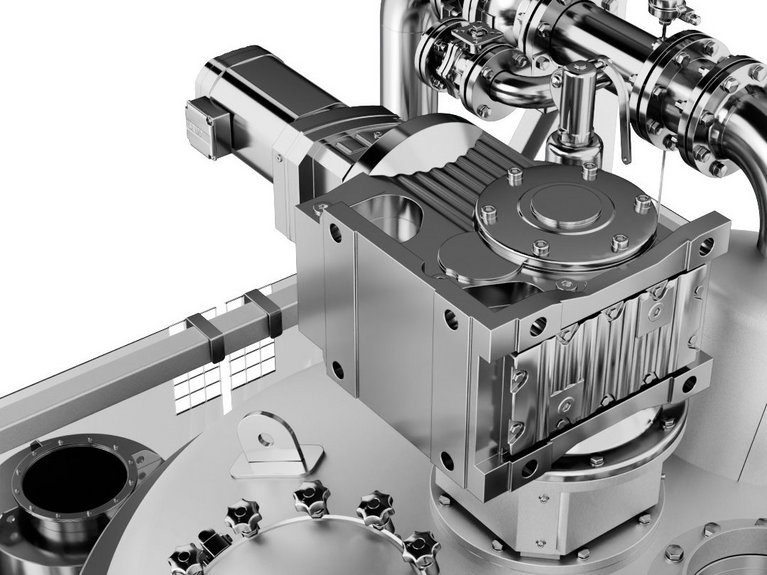

With finely adjustable settings for heat, pressure, and steam, the BDB activates the essential "popping" effect – separating the pulp from the shell to enable efficient extraction of the cocoa nibs. This precision significantly improves processing efficiency and final product quality.

Typically positioned downstream of the Lehmann CCL Continuous Conditioner Louver, the BDB plays a vital role in preparing cocoa nibs for roasting by supporting consistent and effective pre-treatment.

Beyond nib preparation, the BDB also excels at debacterization of whole cocoa beans after roasting in the Lehmann CRL Continuous Roaster Louver. Through accurate control of key process parameters – including steam, temperature, and treatment time –the BDB ensures reliable monitoring of all Critical Control Points (CCPs), guaranteeing a safe, high-quality, and regulation-compliant roasting process.

VERSIONS

| Versions | BDB 350 | BDB 500 | BDB 1000 | BDB 1500 | BDB 2000 |

|---|---|---|---|---|---|

| Capacity [kg] | 350 | 500 | 1000 | 1500 | 2000 |

| Steam requirement [kg/h] | 100–150 | 100–150 | 200 | 300 | 400 |

| Connected load [kW] | 19 | 19 | 26 | 26 | 26 |