Log5 Continuous Pasteurizer

Pasteurization of Nuts

Built to solve. Designed to deliver.

Food safety is critical in preventing outbreaks of foodborne illnesses such as Salmonella. The Log5 Continuous Pasteurizer delivers an optimal solution for the effective inactivation of harmful bacteria in nut products. Designed to achieve a validated 5-log pathogen reduction, it ensures the highest safety standards – without compromising the product’s original quality.

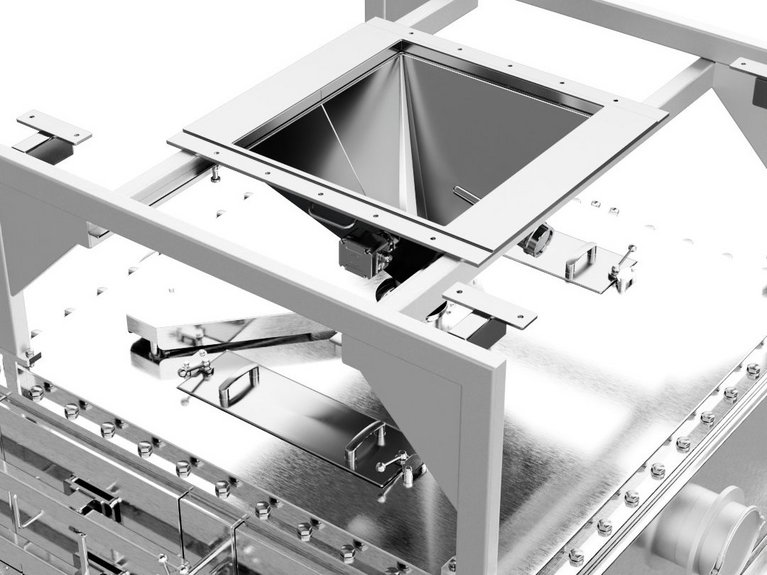

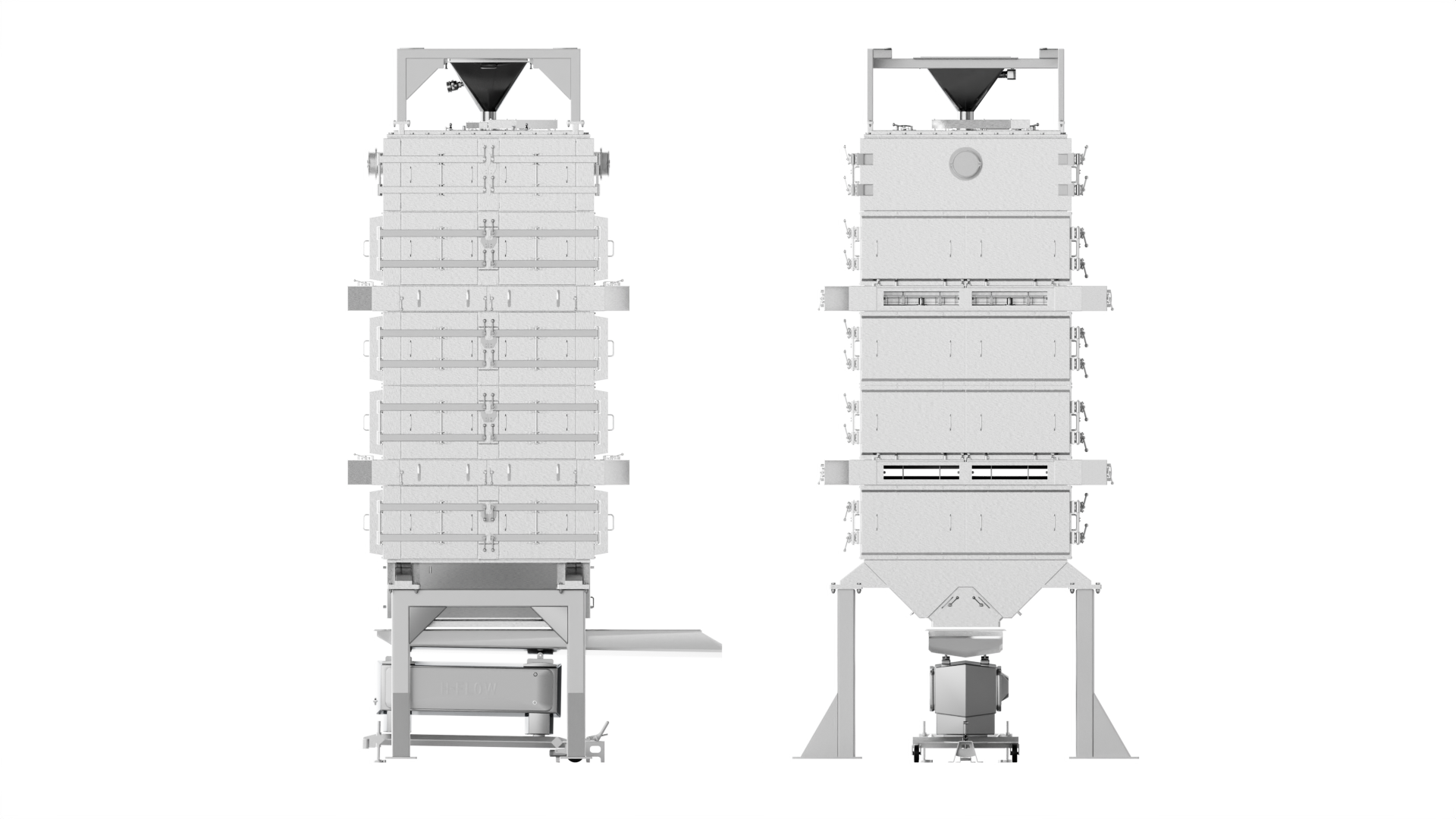

During preheating, the product is gently fed from the top of the treatment unit and conveyed downwards through several treatment levels. As it descends, it is continuously and gently mixed. Hot air is introduced at the bottom of the unit and rises in a counter-current flow, ensuring uniform heat distribution.

Pasteurization takes place within the same unit, providing a highly controlled environment where water activity, temperature, relative humidity, airflow, air volume and dwell time are precisely managed. The preheating phase prevents excessive moisture uptake and only increases the surface water activity of the nuts. This creates optimal conditions for pathogen inactivation, achieving a validated 5-log reduction.

The product is gently transferred from tray to tray throughout the process, ensuring uniform treatment and consistent pasteurization.

After pasteurization, the product is rapidly cooled using vertical counter-current cooling technology. This step stabilizes the product and preserves its original characteristics, ensuring quality and safety.

Versions

| AwCP 10 | AwCP 23 | |

|---|---|---|

| Capacity [kg/h] | 1,000–2,200 | 2,200–5,000 |