MDB Microbatch DeBacterizer

Popping / Debacterization of raw cocoa beans for cocoa processing

Built to solve. Designed to deliver.

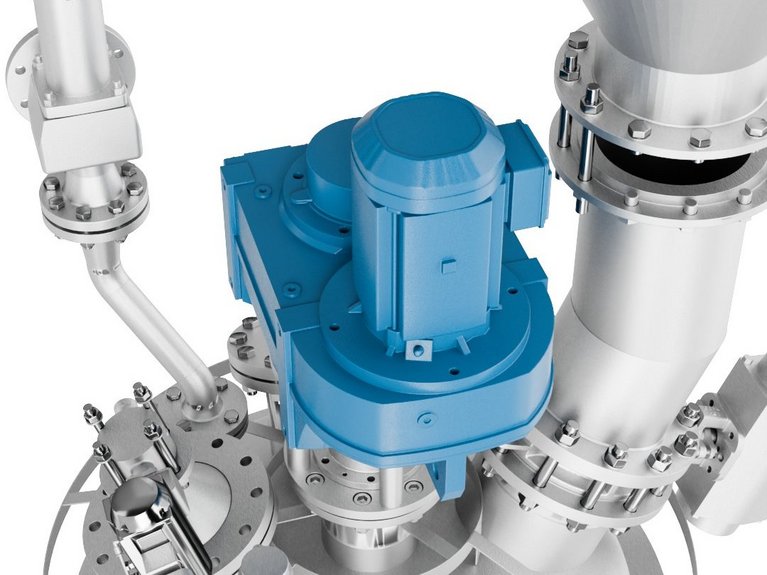

The PROBAT MDB Microbatch DeBacterizer is specifically engineered for the pre-treatment of raw cocoa beans, initiating the separation of shell and nibs through targeted steam application. This controlled process reduces yield losses and ensures that shell/nib separation complies with stringent regulatory quality standards.

Equipped with finely adjustable settings for heat, pressure, and steam, the MDB promotes the “popping” effect – an essential step in which the pulp is separated from the shell to enable efficient kernel separation. This precision enhances processing efficiency and product quality.

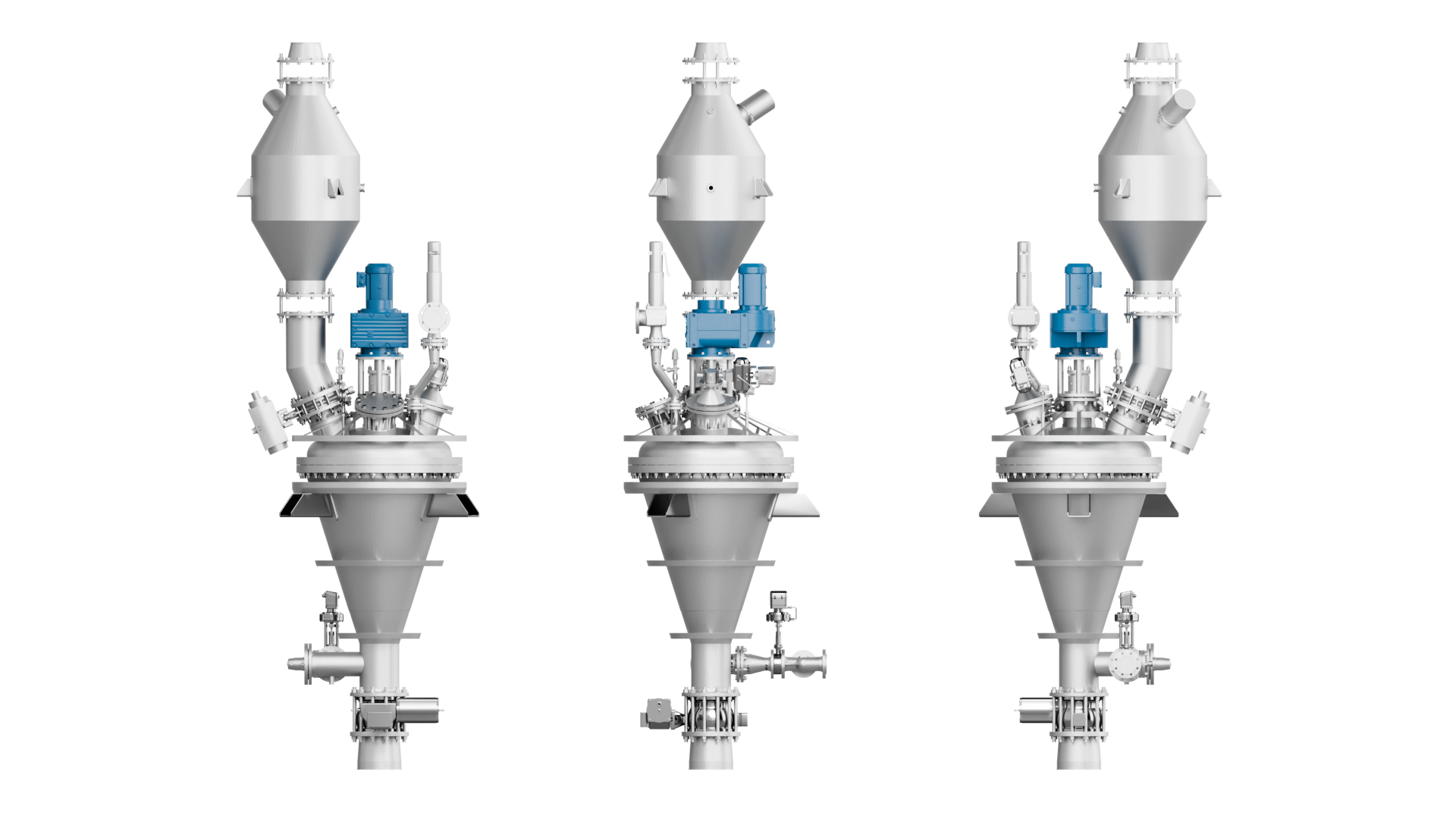

The MDB is commonly integrated upstream of the PROBAT CCS Continuous Conditioner Shaft, where it plays a key role in the initial pre-treatment phase prior to cocoa nib roasting.

In addition to nib preparation, the MDB also supports effective debacterization of whole cocoa beans before roasting in the PROBAT CRS Continuous Roaster Shaft. By accurately controlling critical process parameters – steam, temperature, and treatment duration – the MDB enables consistent monitoring of all Critical Control Points (CCPs), ensuring a safe and high-quality roasting process.

VERSIONS

| MDB 2000 | MDB 4000 | |

|---|---|---|

| Capacity [kg] | 120 | 200 |

| Capacity [kg/h] | 2,000 | 4,000 |

| Steam requirement [kg/h] | 450 | 650 |

| Connected load [kW] | 2 | 3 |