BMC Ball Mill Chocolate

Continuous ball mill for grinding chocolate, compound, creams, nut and other pastes

Built to solve. Designed to deliver.

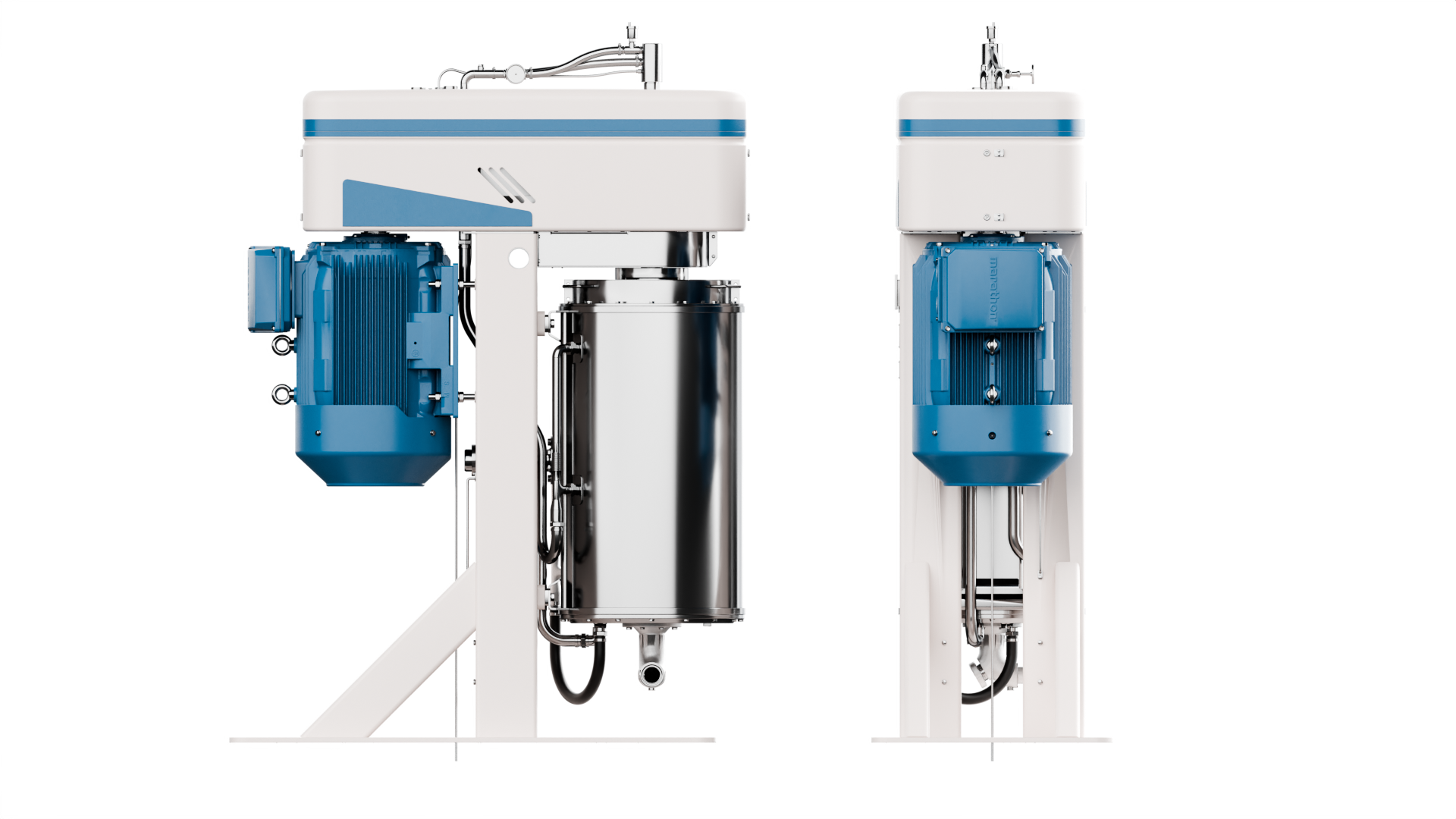

The Wiener BMC Ball Mill Chocolate is specifically designed for efficient grinding of high viscosity pre-mixed pastes such as chocolate, compound, creams and nut or seed based formulations.

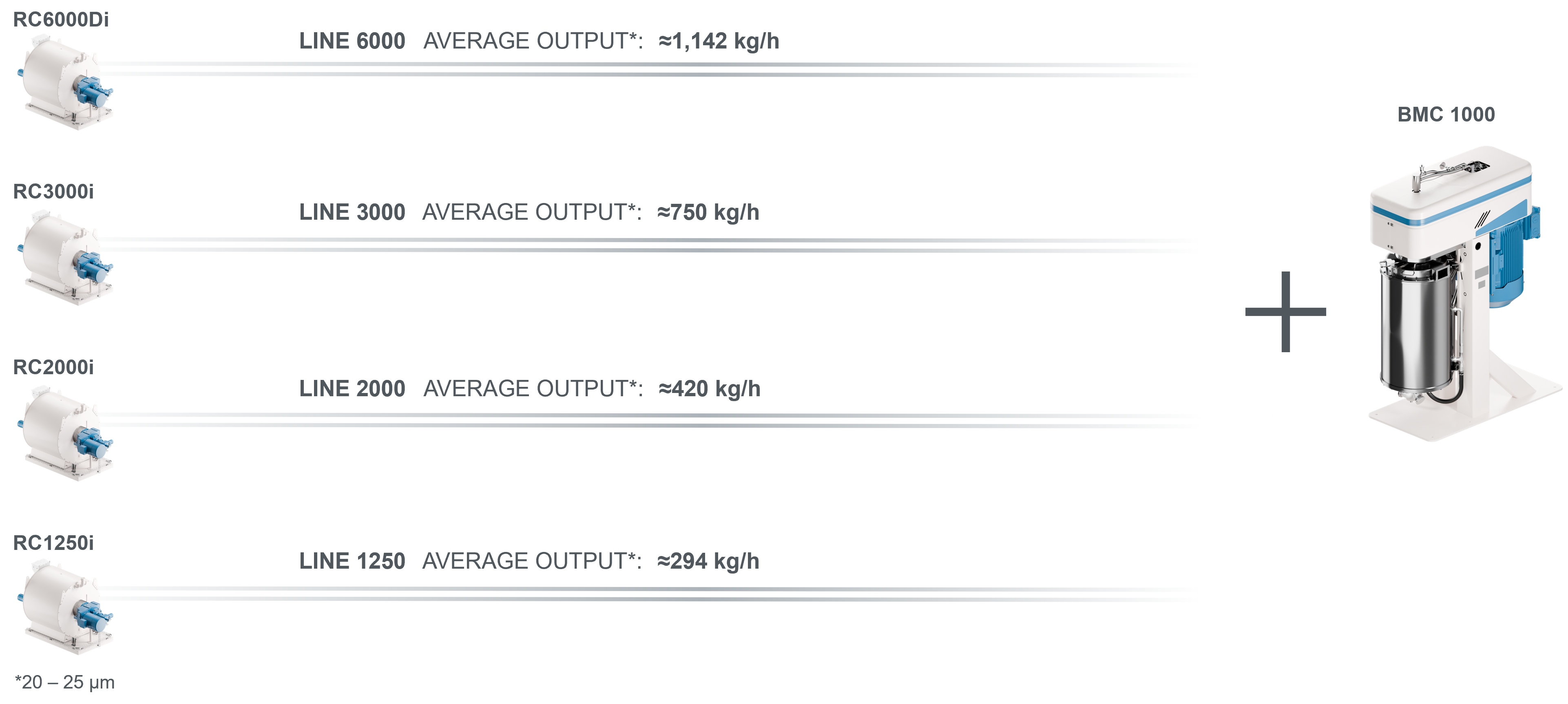

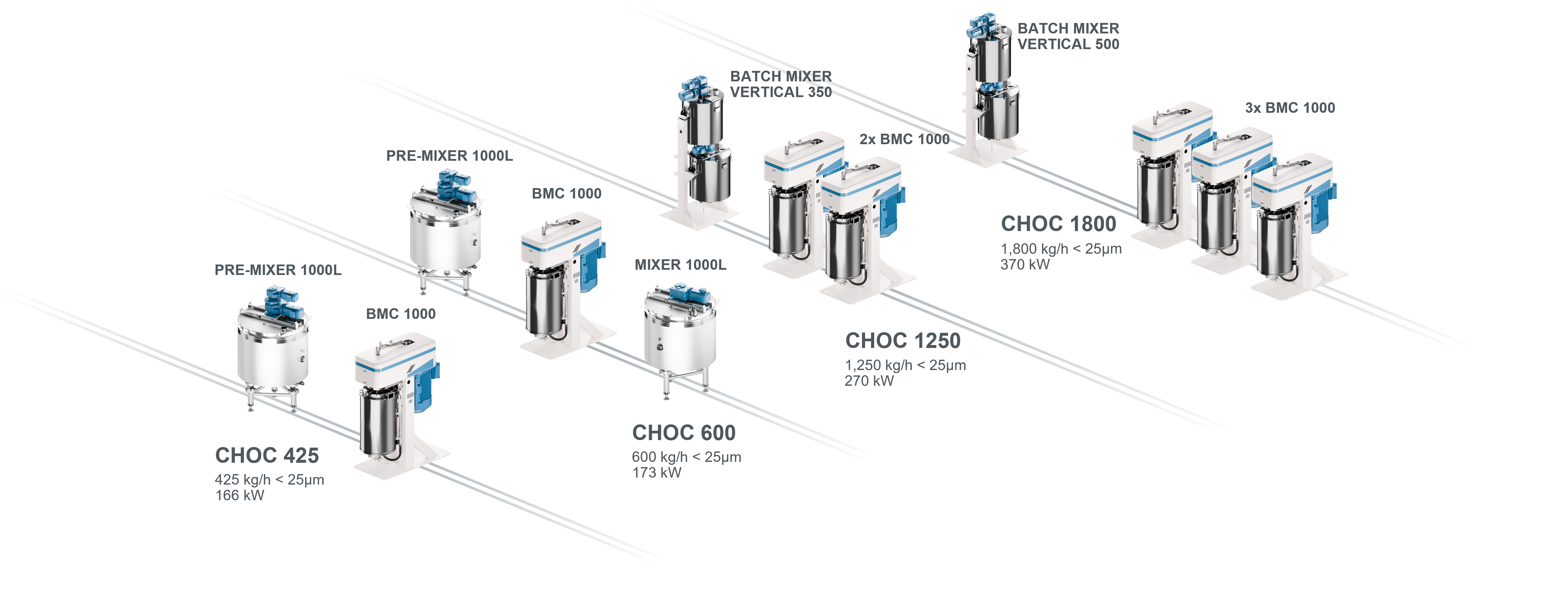

To optimize processing times and maximize throughput, the BMC can be seamlessly integrated into a refining system – operating in-line with one or more additional ball mills following one or more BMV Batch Mixer Vertical. It serves as a key component of the CHOC and QCHOC lines, enabling streamlined, high-efficiency production. When positioned downstream of the MACINTYRE Refiner/Conche, the BMC also becomes an integral part of the MACINTYRE/WIENER continuous processing line.

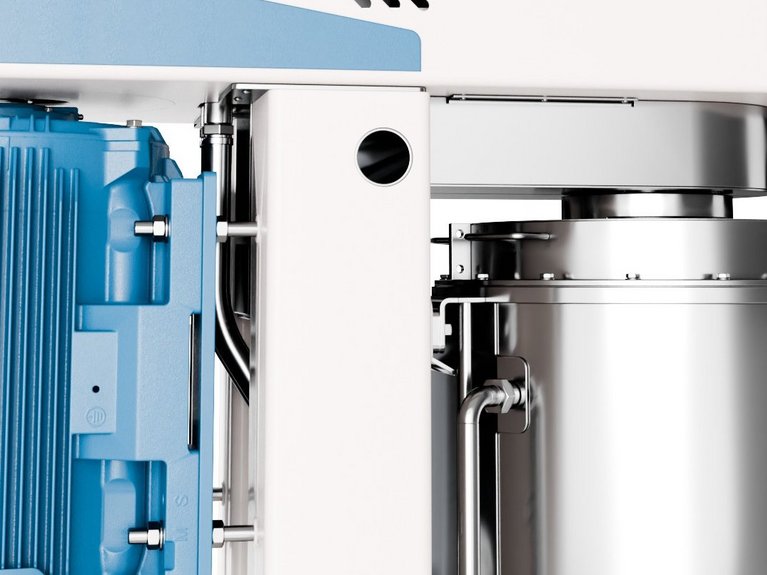

Grinding is achieved via a vertical, jacketed tank with a rotating shaft fitted with agitator arms and filled with hardened steel balls. As the product circulates from bottom to top, it is refined through continuous friction between the grinding media. Precise control of pump speed and pressure ensures optimal fineness – achieving particle sizes below 20 µm with excellent distribution.

Advanced vessel design, shaft-pin configuration, and parameter control make this one of the most efficient ball mills available today.

VERSIONS

| Wiener BMC 1000 | |

|---|---|

| Capacity [kg/h] | 500–1,800 |

| Connected Load [kW] | 92.5 |

CHOC LINE

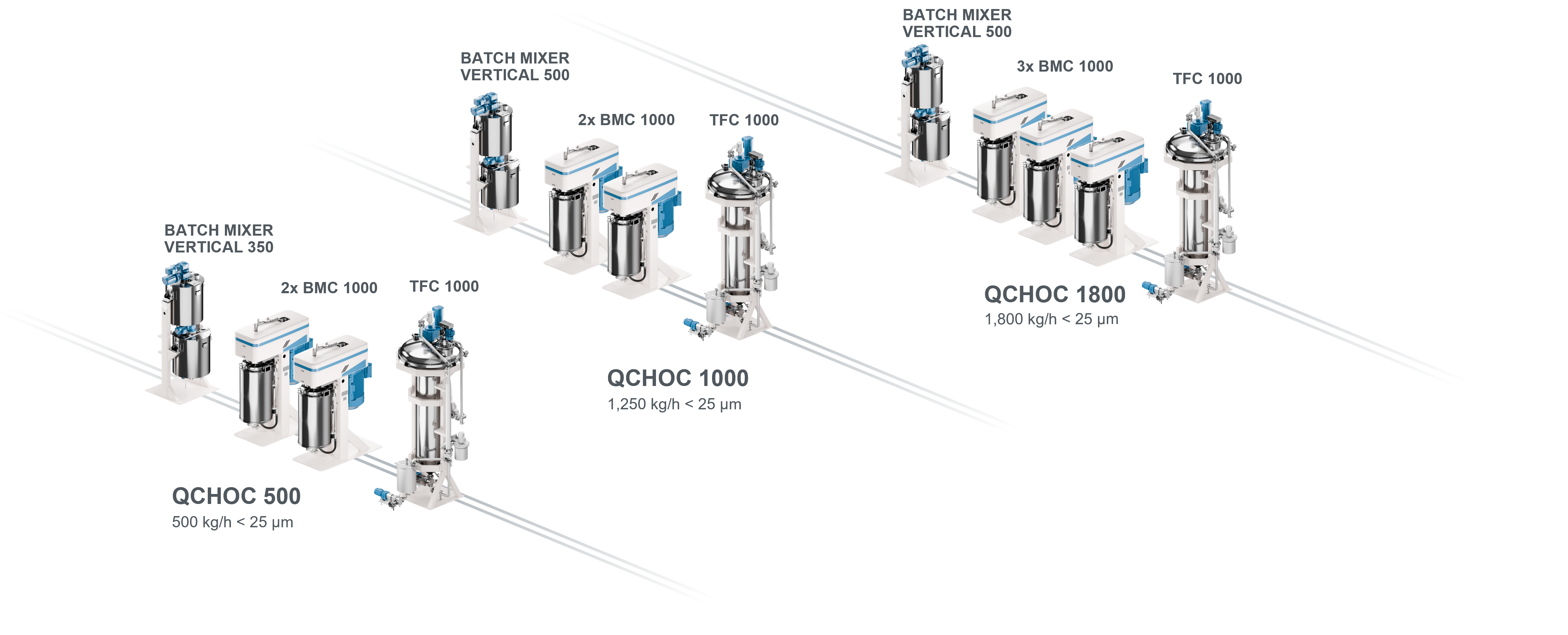

QCHOC LINE

MACINTYRE/WIENER