BML Ball Mill Liquor

Continuous ball mill for fine and superfine grinding of pre-ground cocoa liquor

Built to solve. Designed to deliver.

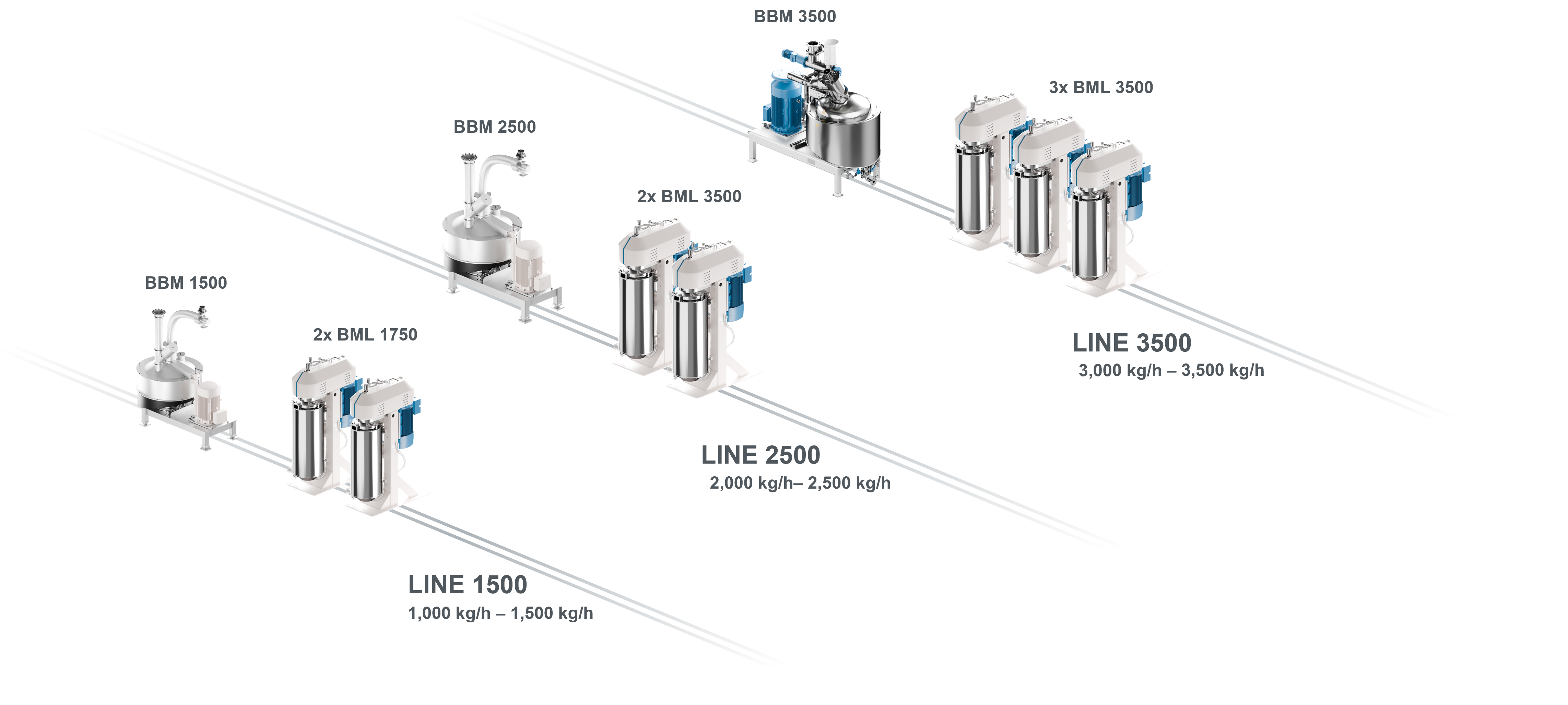

The Wiener BML Ball Mill Liquor is specifically designed for gently grinding pre-ground cocoa liquor to a fine or superfine consistency. In a multi-stage configuration — typically following the BBM Beater Blade Mill — multiple BML units can be used in sequence to optimize processing time and maximize throughput, delivering consistent results on an industrial scale.

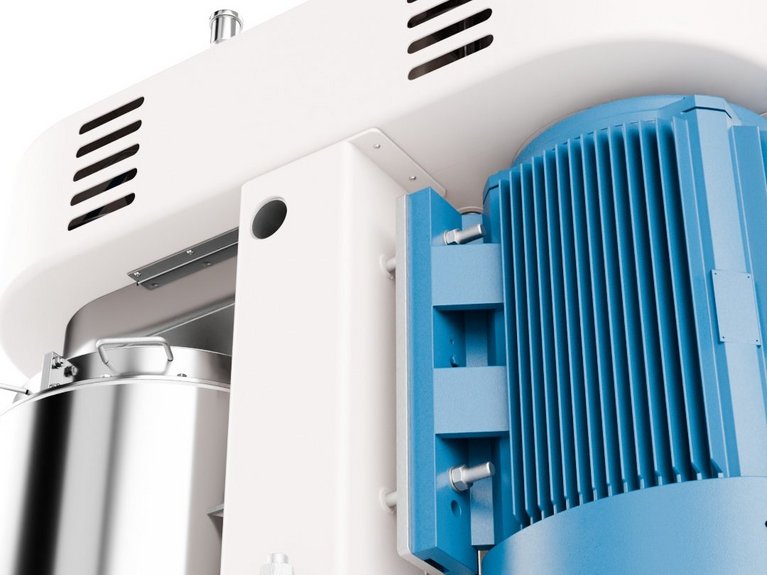

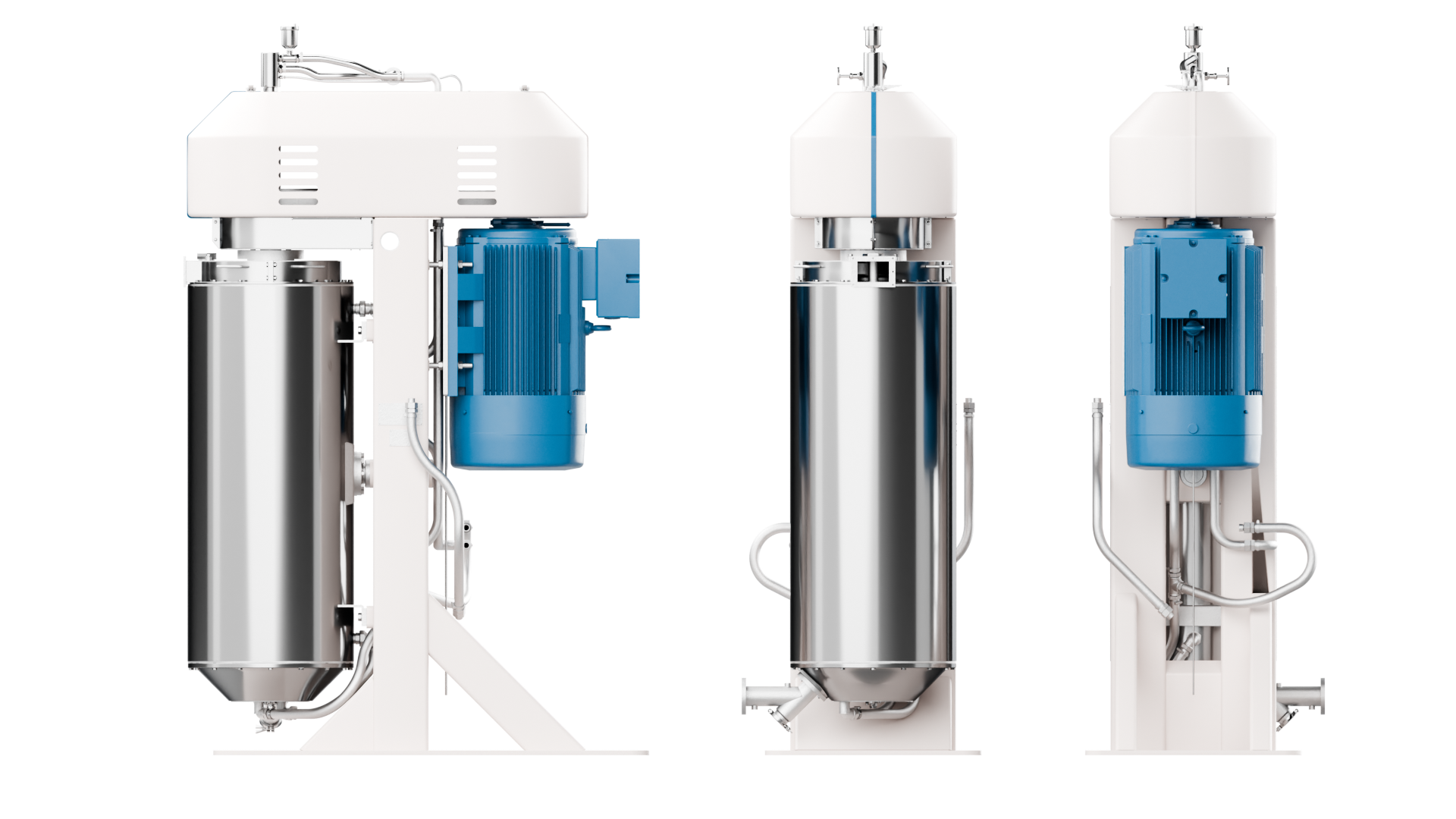

The grinding process in the BML takes place in a vertically oriented, jacketed tank, featuring a rotating shaft with precision-engineered agitator arms. Hardened steel balls serve as the grinding medium, refining the product through continuous upward circulation and controlled friction.

Thanks to its advanced vessel geometry, optimized shaft-pin configuration, and intelligent parameter control, the BML is among the most efficient and reliable ball mills on the market today.

Versions

| Versions | Wiener BML 1750 | Wiener BML 3500 |

|---|---|---|

| Capacity [kg/h] | 750–1,750 | 1,800–3,500 |

| Volume of grinding chamber [l] | 180 | 430 |

| Connected load [kW] | 48 | 103 |