GM Series

Gap Mill for grinding cocoa, nut and sugar

Built to solve. Designed to deliver.

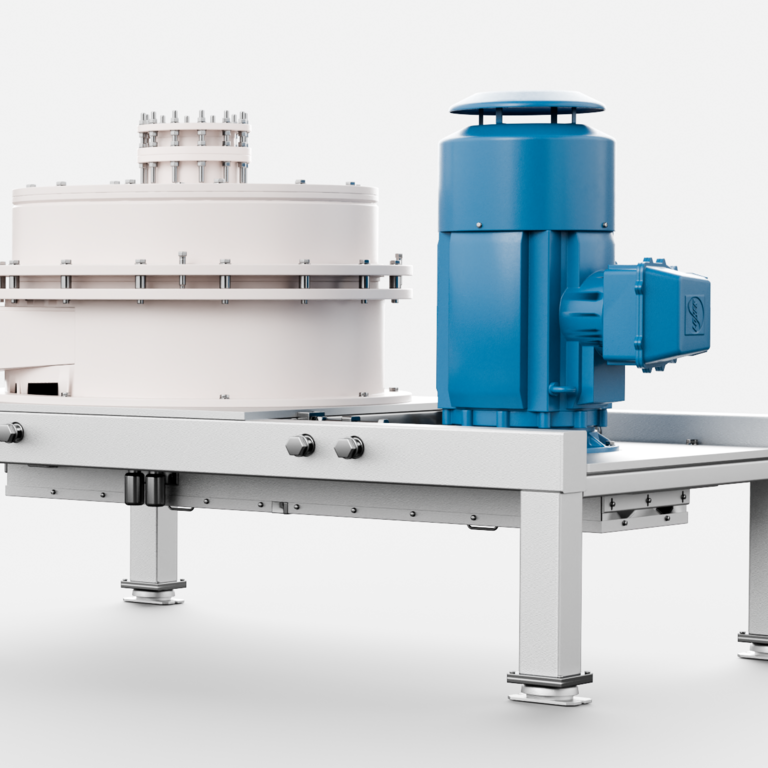

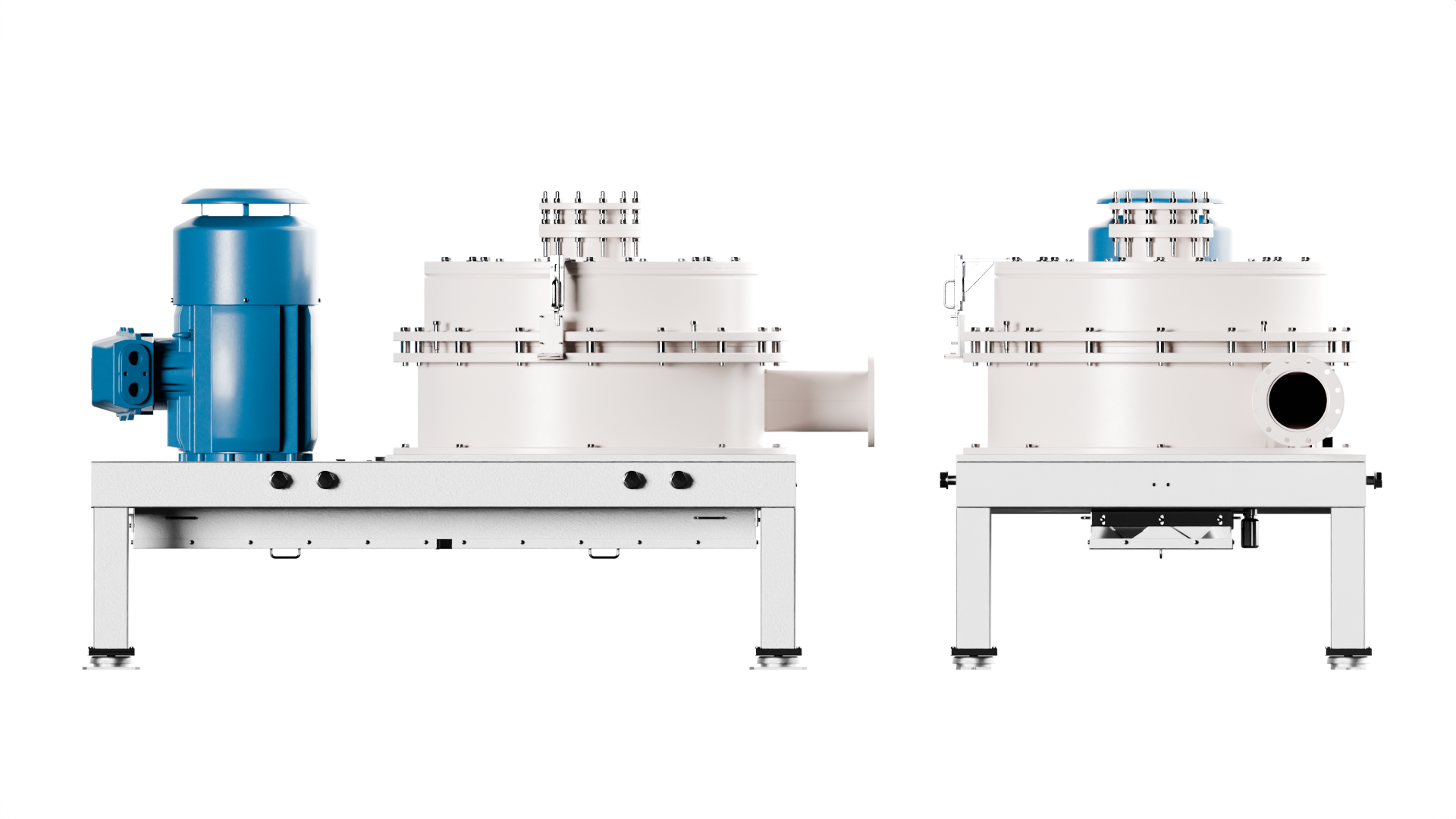

The Bauermeister GM Gap Mill is engineered for fine to ultra-fine dry grinding of brittle bulk materials. Thanks to its screenless discharge design, the GM is especially well-suited for processing fibrous and fat-containing materials such as sugar, starch, soya, nuts, ginger, and cocoa but also grains, seeds and legumes. Precision is ensured through an adjustable grinding gap and variable rotor speed. When paired with the CL Air Classifier, particle sizes below 20 µm can be consistently achieved.

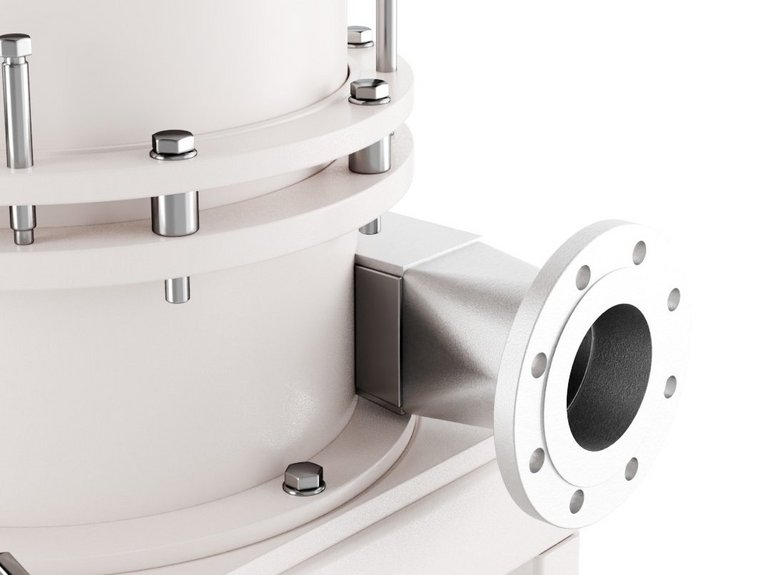

Material is carefully fed into the GM, where it is swiftly accelerated outward by the high-speed rotating grinding element. Pre-crushing occurs at the top edges of the fine grinding tools, after which the material is drawn through the grinding gap between the rotor and stator by air suction. The grinding process continues as particles are impacted along the U-shaped grinding elements positioned around the mill’s outer circumference, before being drawn through the stainless steel tangential discharge pipe at the bottom.

VERSIONS

| Bauermeister GM 20.1 | Bauermeister GM 40.1 | Bauermeister GM 80.1 | Bauermeister GM 120.1 | |

|---|---|---|---|---|

| Capacity Factor | 0.6 | 1 | 1.8 | 2.8 |

| Rotor Diameter [mm] | 200 | 400 | 800 | 1,200 |

| Connected Load [kW] | 22 | 45 | 90 | 200 |