BBM Beater Blade Mill

Beater blade mill for pre-grinding of cocoa nibs, nuts and almonds

Built to solve. Designed to deliver.

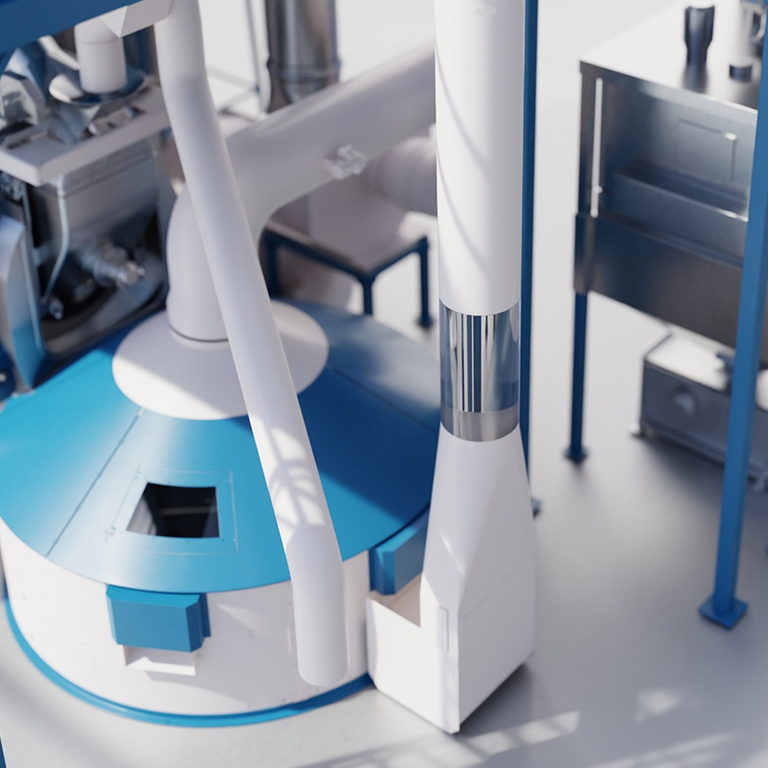

The Duyvis BBM Beater Blade Mill has been expertly engineered for pre-grinding cocoa nibs, nuts, almonds and other high-fat or high-oil seeds. Its precise particle size output makes it an ideal pre-treatment for fine grinding processes in BML ball mills and other refining equipment.

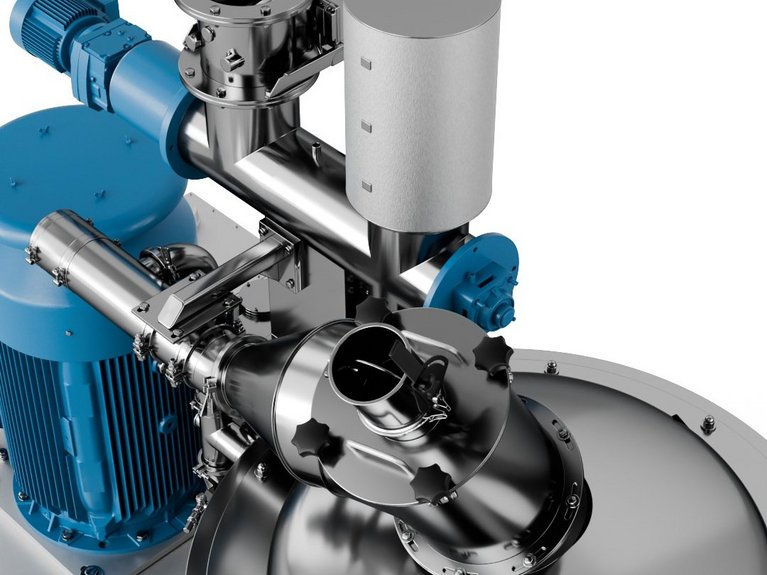

Material is fed from the top into the grinding chamber via a dosing screw, where specially hardened steel knives immediately and efficiently reduce the material in size. These high-durability blades ensure minimal wear, reducing downtime and maintenance costs.

Optional inline detection of high acidity and moisture levels enables downstream process optimization via the Flavor Monitoring Cockpit.

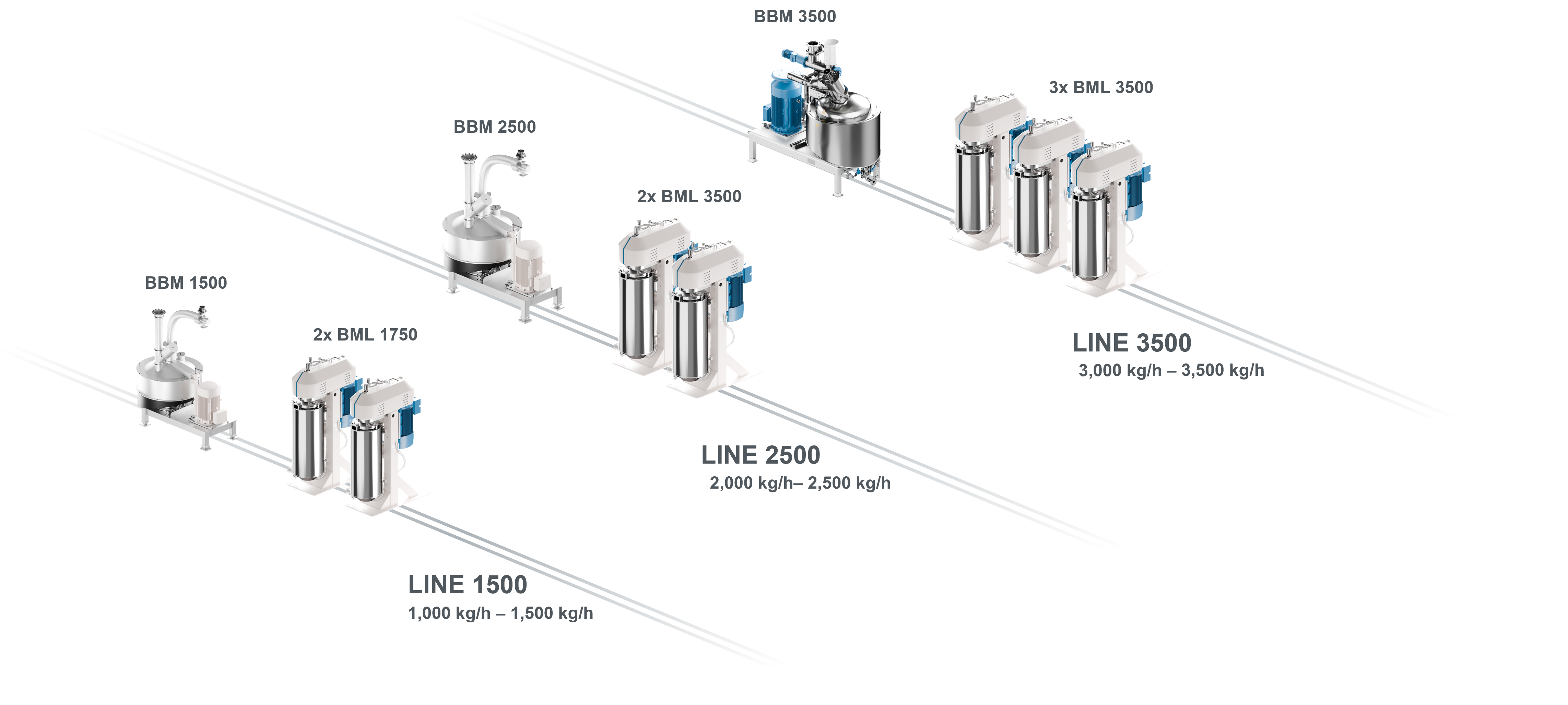

Versions

| Duyvis BBM 1500 | Duyvis BBM 2500 | Duyvis BBM 3500 | |

|---|---|---|---|

| Capacity [kg/h] | 1,000–1,500 | 1,500–2,500 | 2,500–3,500 |

| Volume Grinding Chamber [l] | 140 | 490 | 600 |

| Connected Load [kw] | 55 | 110 | 160 |