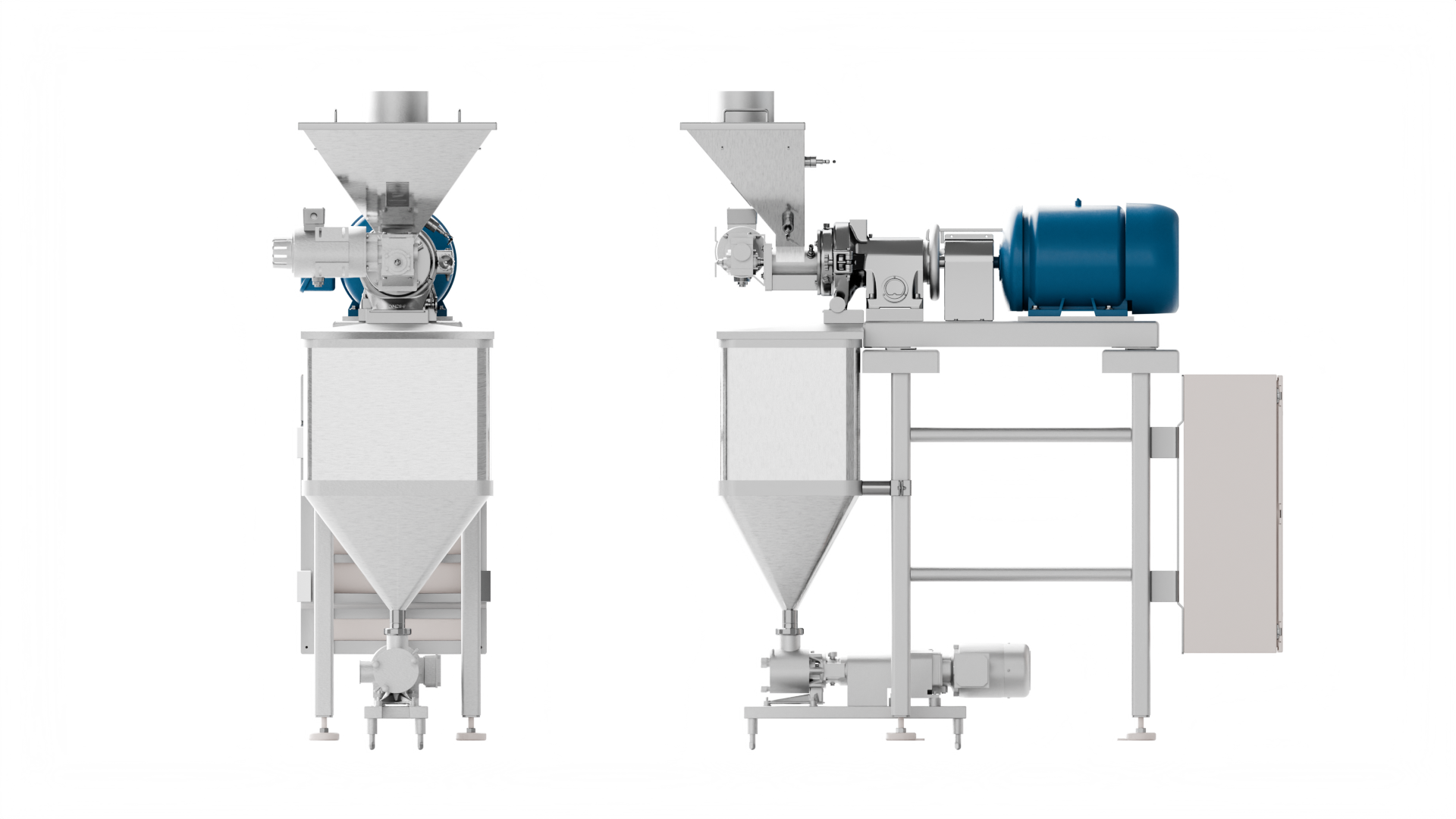

BMN Butter Mill Nuts

Coarse and fine grinding of peanuts and tree nuts

Built to solve. Designed to deliver.

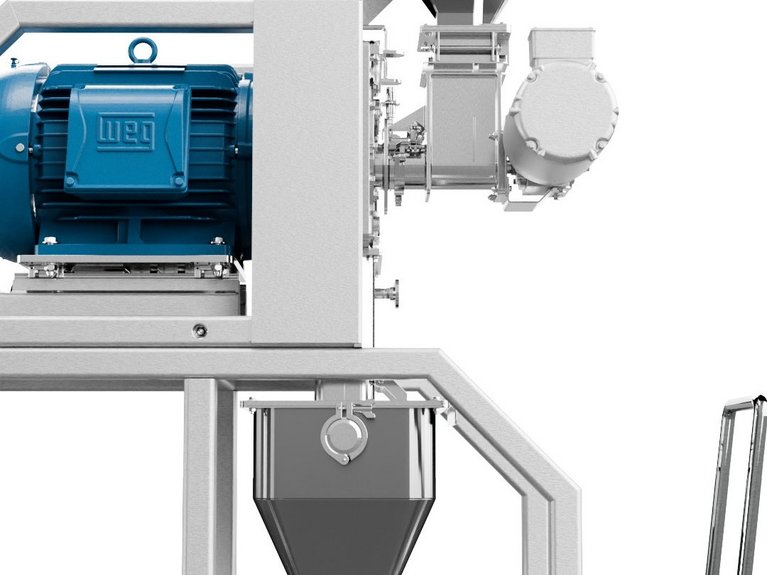

The highly versatile Horn BMN Butter Mill Nuts is engineered to grind a wide range of peanuts and tree nuts with exceptional precision and reliability. Renowned for its unmatched performance in handling product variability and maximizing machine uptime, it is the ideal solution for producing smooth, easy-to-spread nut butters. The mill seamlessly incorporates stabilizers, salt, dextrose, and other ingredients to create a consistently creamy, homogeneous blend.

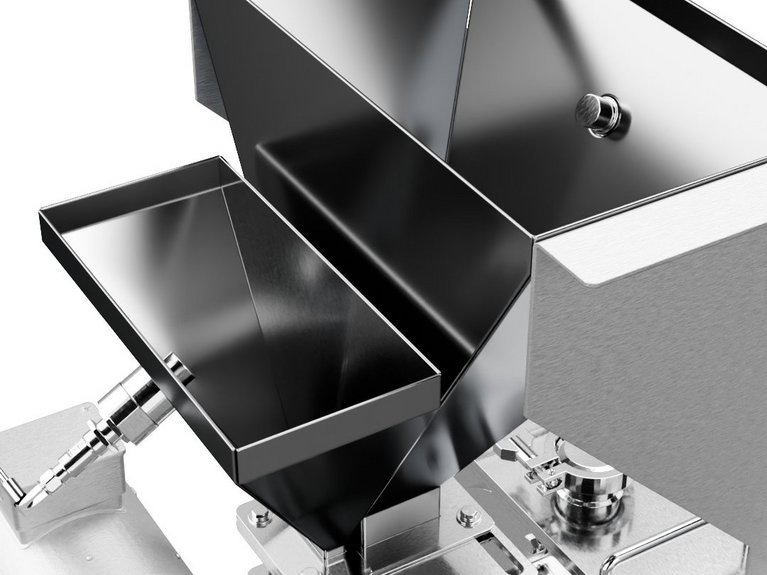

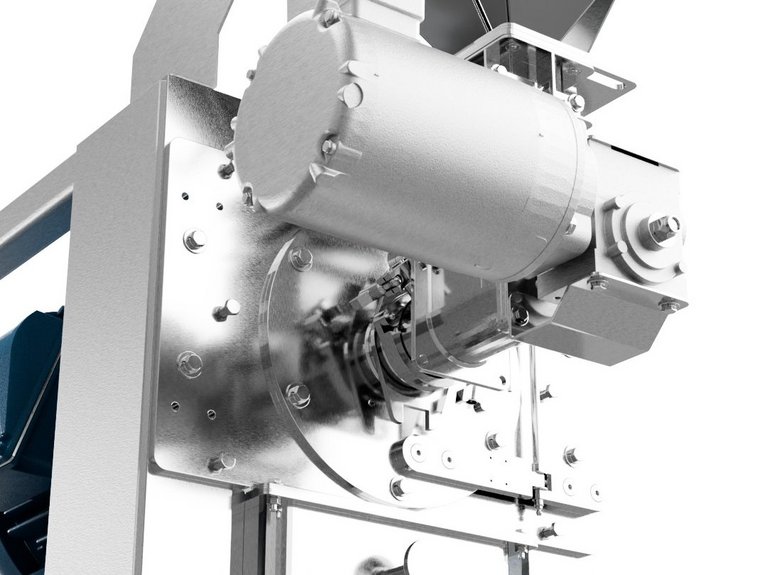

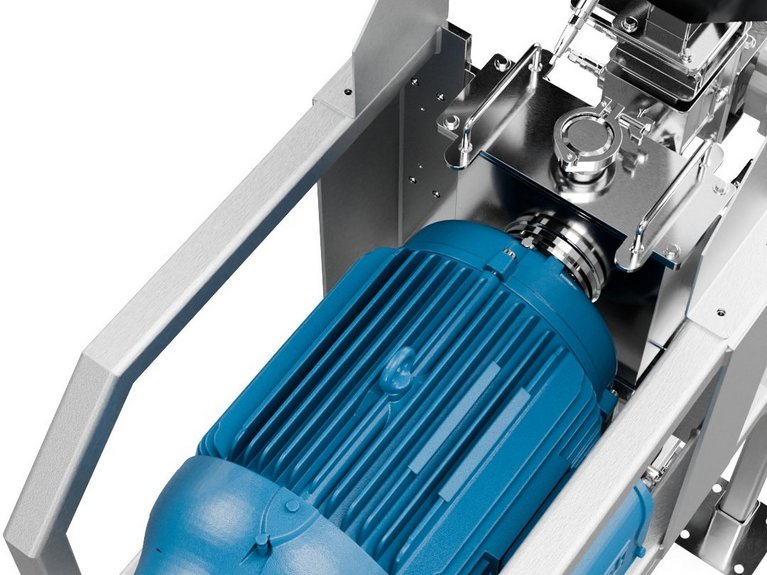

The BMN features a variable-speed auger that precisely and consistently meters product into the grinding chamber. Inside, parallel grinding plates blend nuts with dry and liquid ingredients to produce a smooth, uniform paste. The six interchangeable grinding plates offer distinct control over particle size distribution, enabling the creation of tailored texture profiles. The variable-speed drive enables the grinding speed to be dynamically adjusted to meet the requirements of specific recipes, while automatic gap control provides real-time optimization, enhancing throughput and minimizing downtime. With 50% less maintenance, fewer failure points and simplified troubleshooting, the direct drive design of the BMN significantly reduces mechanical complexity, resulting in superior operational efficiency.

Versions

| Horn BMN 900 | Horn BMN 3000 | Horn BMN 5400 | Horn BMN 3400 | |

|---|---|---|---|---|

| Plate size [in] | 8 | 18 | 18 | 24 |

| Throughput Primary mill [kg/h] / [lb/h] | 450–900 / 1,000–2,000 | 900–3,000 / 2,000–6,500 | 3,400–5,400 / 7,500–12,000 | 1,800–3,400 / 4,000–7,500 |

| Coarse particle size [µm] | 20–45 | 20–45 | 20–45 | 20–45 |

| Throughput Secondary mill [kg/h] / [lb/h] | 450–900 / 1,000–2,000 | 900–3,000 / 2,000–6,500 | 3,400–5,400 / 7,500–12,000 | 1,800–3,400 / 4,000–7,500 |

| Fine Particle size [µm] | 10–15 | 10–15 | 10–15 | 10–15 |

| Connected load [kW] | 25 | 34 | 34 | 60 |