Heidenauer

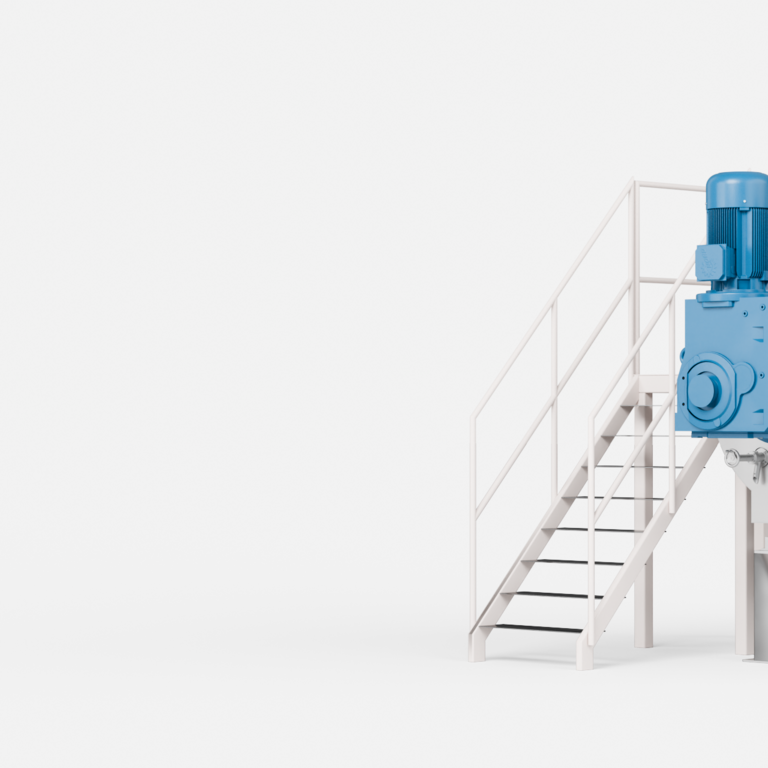

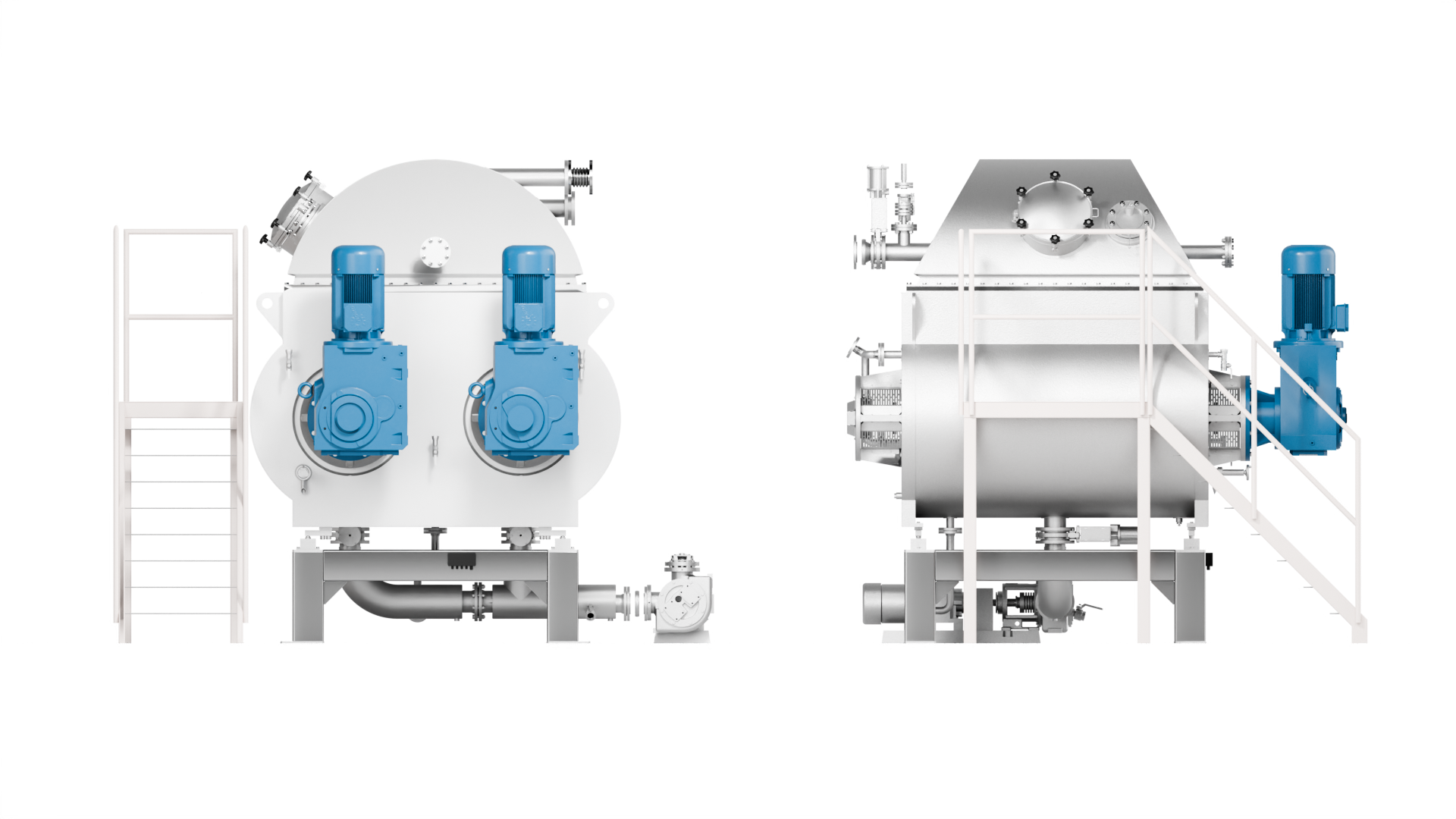

BAL Batch Alkalizer Liquor

Treatment of cocoa liquor

Built to solve. Designed to deliver.

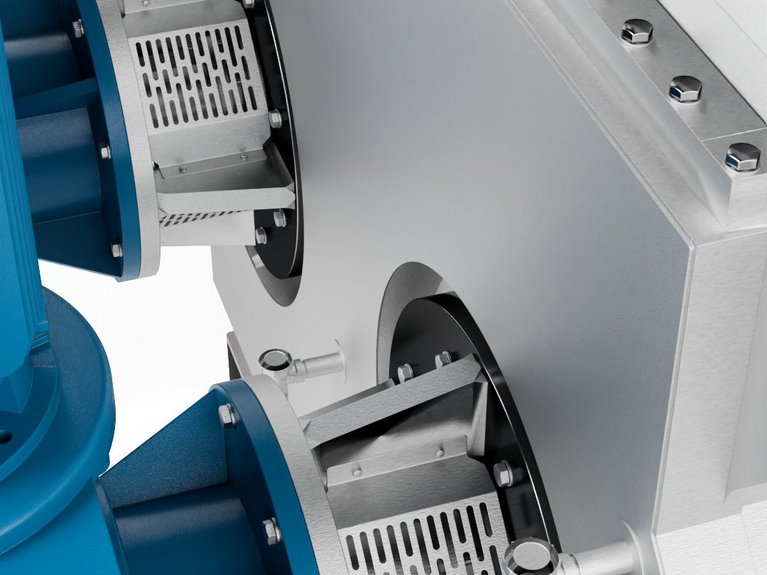

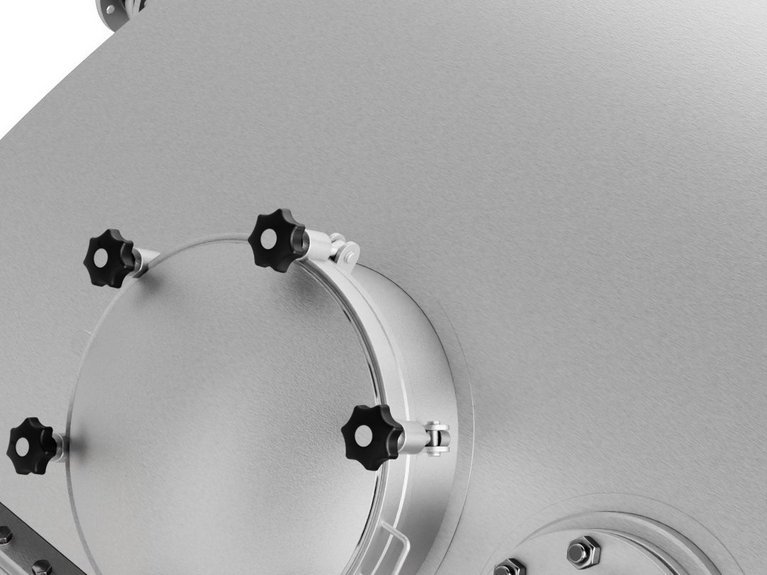

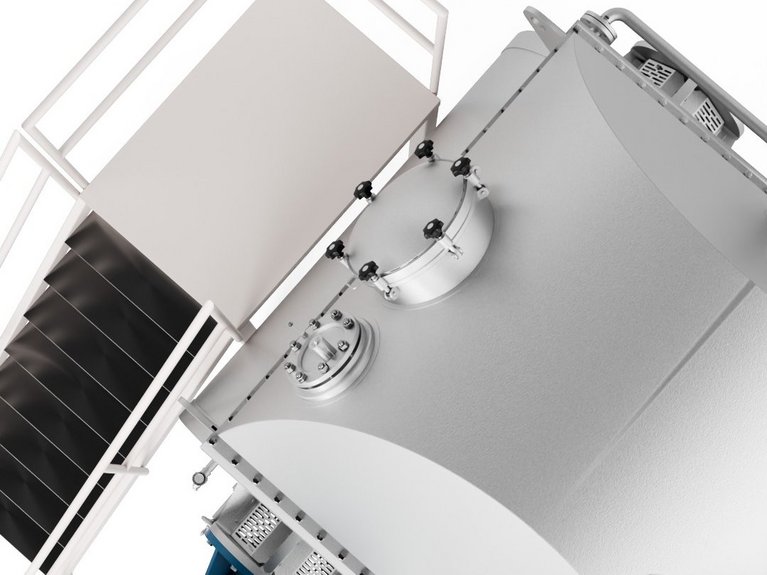

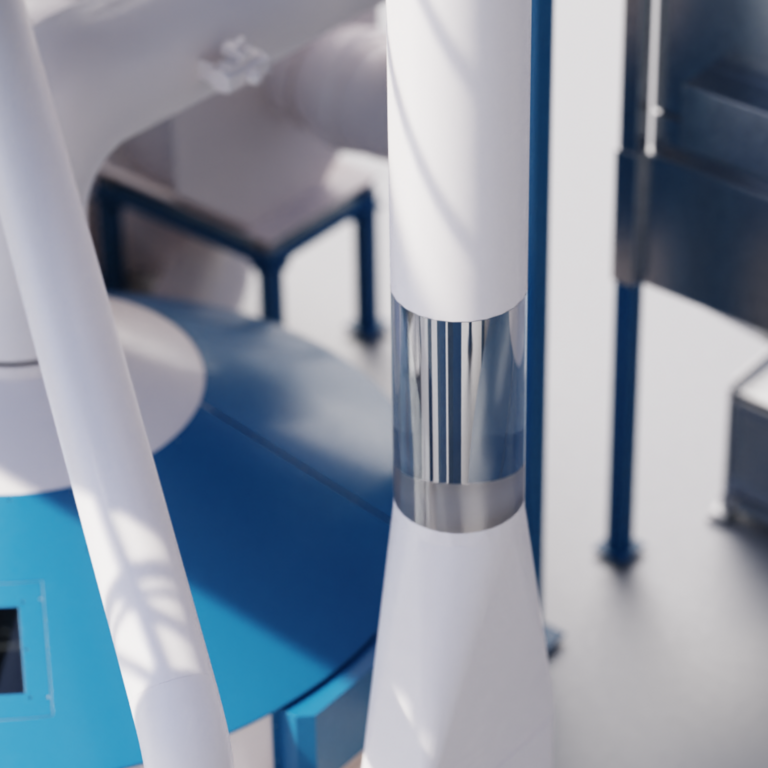

The Heidenauer BAL Batch Alkalizer Liquor provides an effective and traditional method of treating cocoa liquor, serving as an alternative to nib alkalization. Designed to debacterize and alkalize cocoa liquor while significantly reducing downstream processing times, it combines a BMD twin-shaft batch mixer with an integrated vacuum pump.

Specially aligned mixing and kneading elements ensure uniform blending by directing the liquor toward the center of each trough. Heating under vacuum conditions removes excess moisture, acetic acid, and undesirable volatiles – resulting in a cleaner, more balanced cocoa liquor.

Versions

| Heidenauer BAL 3000 | |

|---|---|

| Batch size [kg] | 3,000 |

| Throughput [kg/h] | 1,000 |