BMD Batch Mixer Double

Mixer for compound or chocolate processing

Built to solve. Designed to deliver.

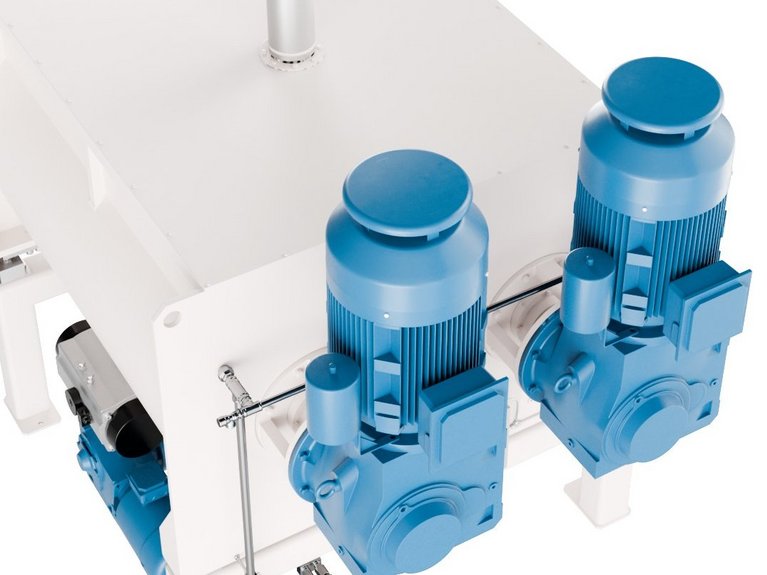

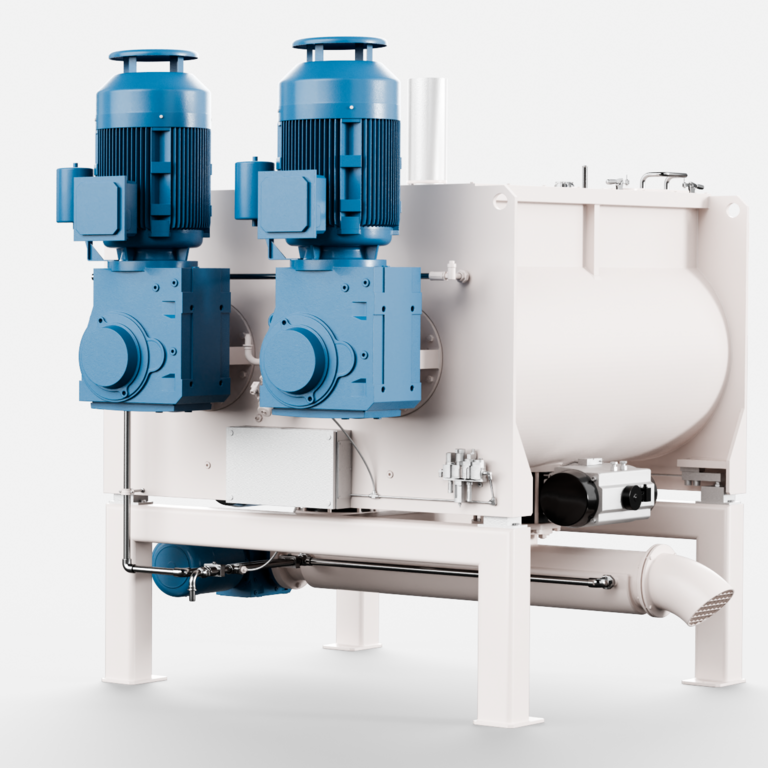

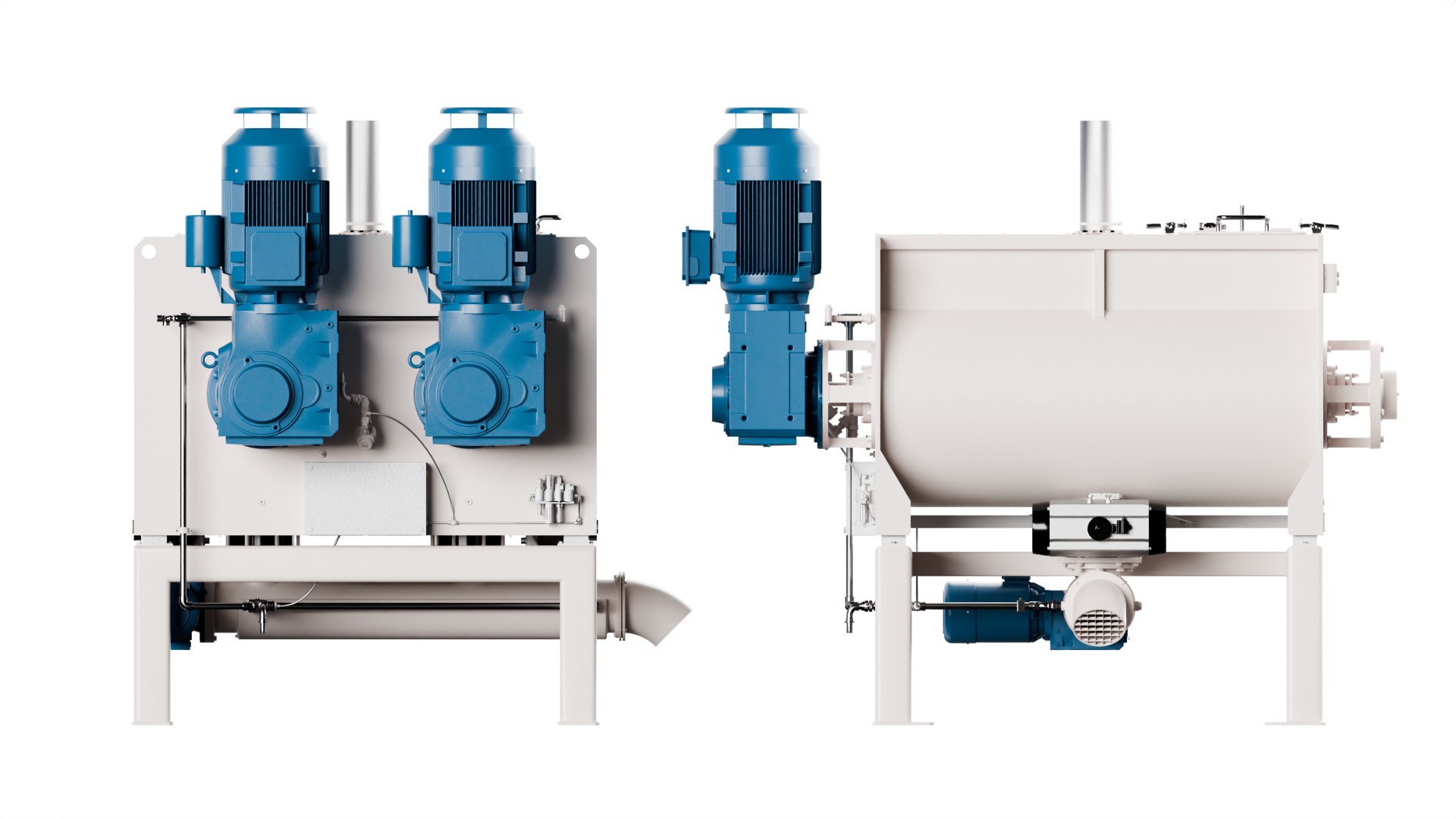

The Heidenauer BMD Batch Mixer Double is engineered for intensive mixing and fast, uniform homogenization of liquids and solids – perfect for chocolate and other confectionery applications. Its horizontal twin-shaft design with a heated double jacket ensures rapid processing, enhancing throughput and consistency in downstream operations.

Two horizontal shafts with precisely aligned mixing elements drive the product toward the center of each trough, ensuring efficient, high-speed homogenization. Frequency-controlled drives optimize product plasticity for refining, while internal scrapers and ball valves minimize residue. Automated recipe management ensures consistent, reliable operation.

VERSIONS

| Heidenauer BMD 500 | Heidenauer BMD 1000 | Heidenauer BMD 2000 | |

|---|---|---|---|

| Batch Size [kg] | 500 | 1,000 | 2,000 |

| Throughput [kg/h] | 2,000 | 3,000 | 6,000 |

| Connected Load [kW] | 27.5 | 42.5 | 79.5 |