BMV Batch Mixer Vertical

Continuous dosing and feeder for processing chocolate and compound masses

Built to solve. Designed to deliver.

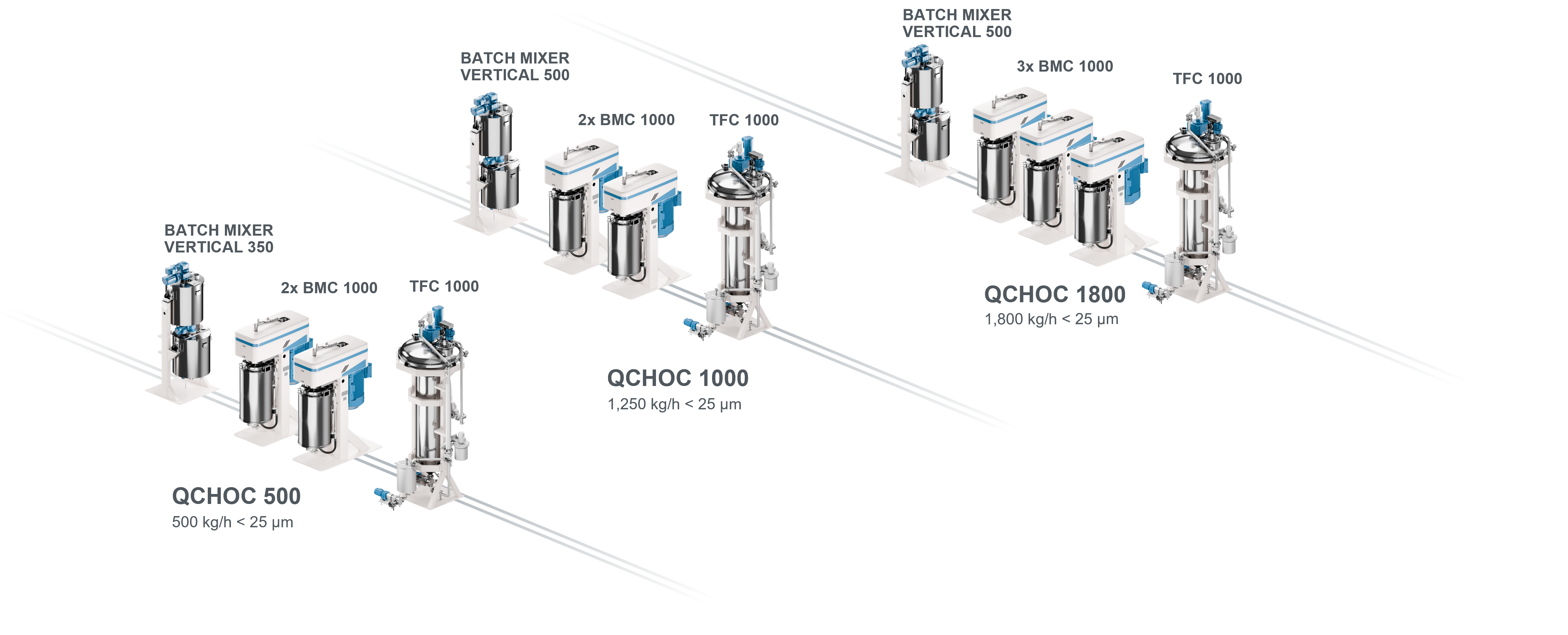

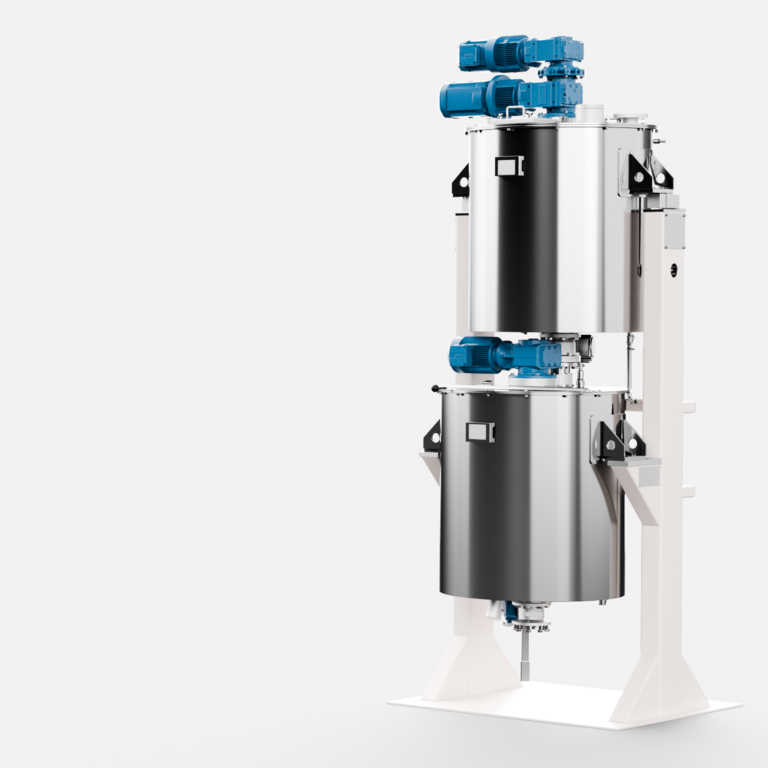

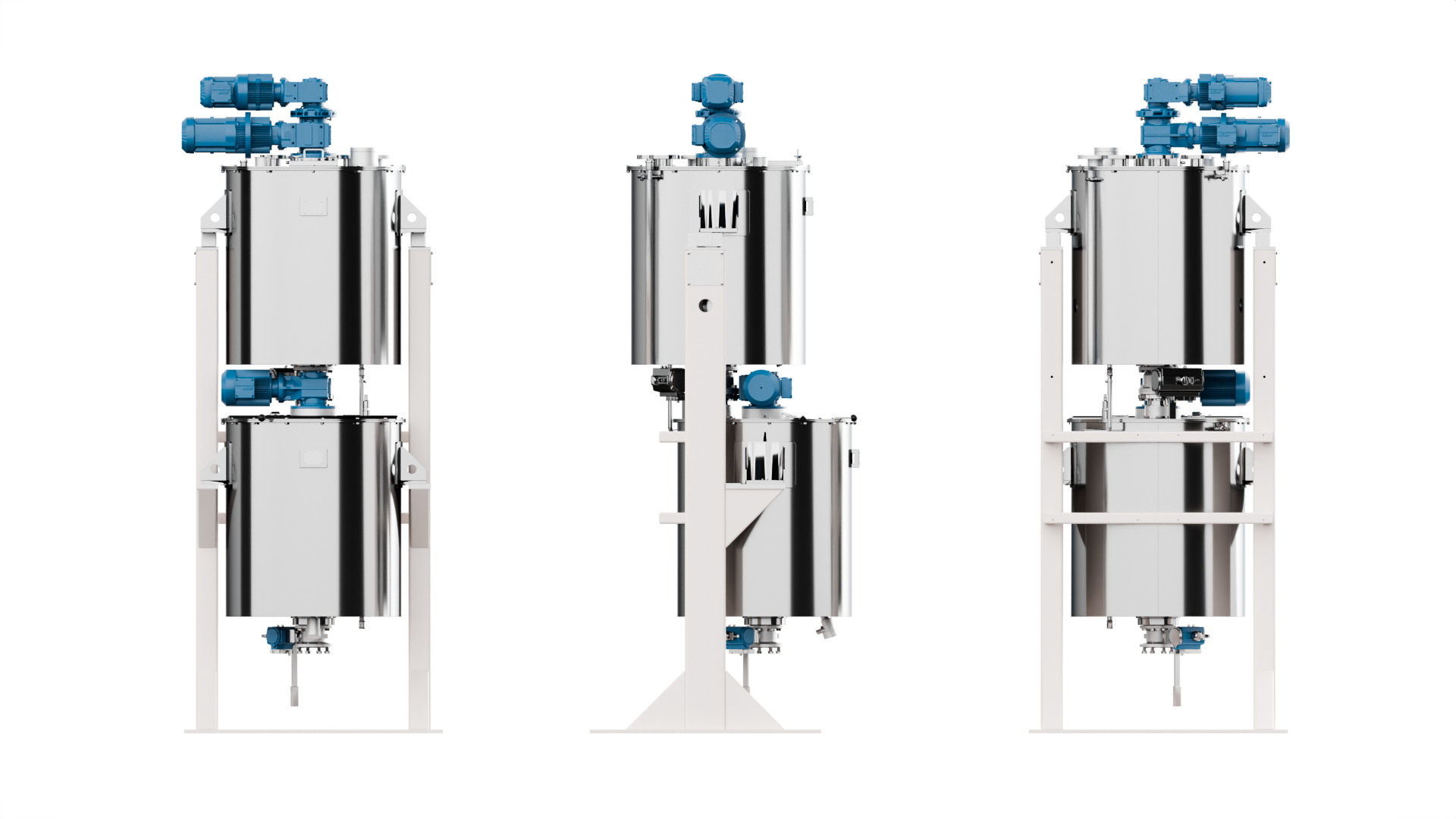

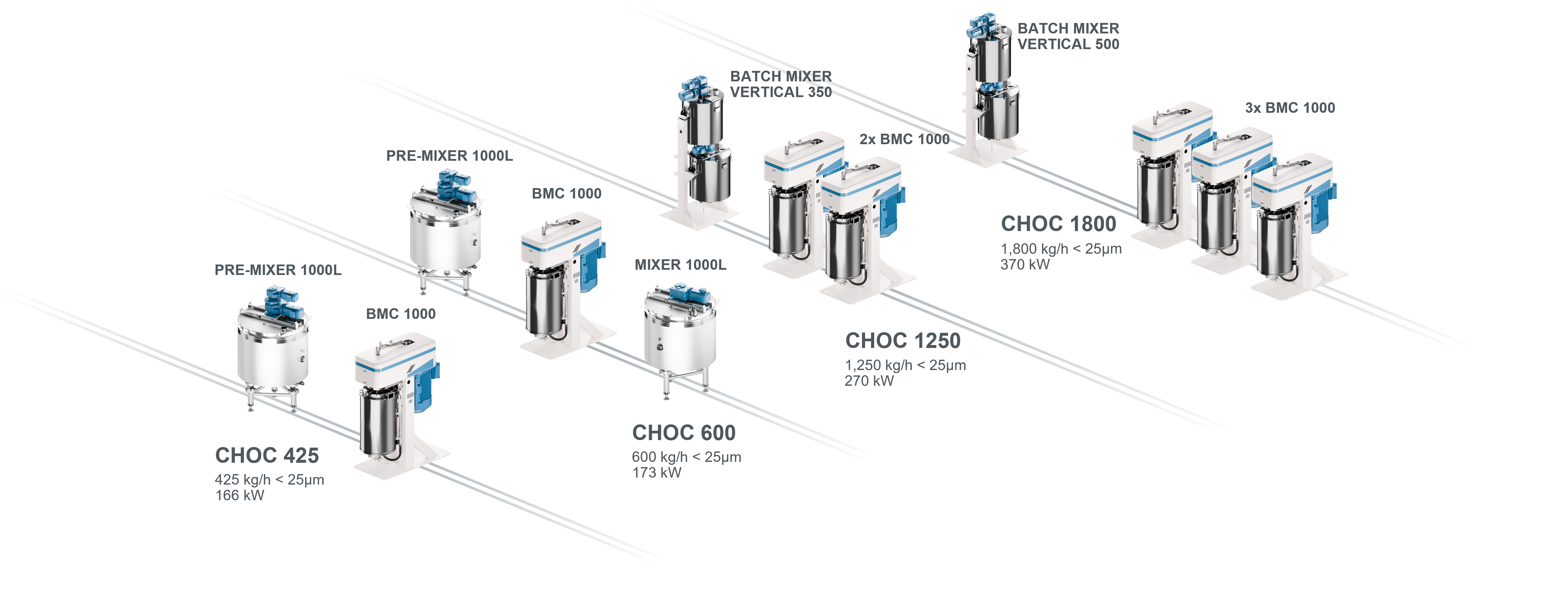

The Duyvis BMV Batch Mixer Vertical is a highly engineered, cost-efficient solution developed for the precise automatic dosing, weighing, and mixing of raw materials. Tailored for the continuous production of chocolate and compound masses, it ensures consistent quality and optimal processing efficiency. The system is seamlessly integrated with two or more units of the BMC Ball Mill Chocolate, forming a critical component of the CHOC and QCHOC Lines for streamlined, high-performance production.

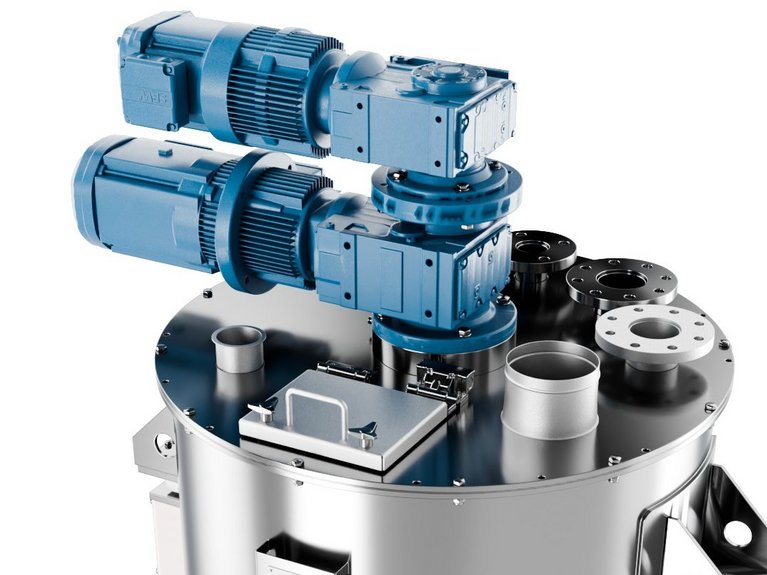

All liquid and dry ingredients are added to the upper chamber of the pre-mixer, either manually or by automatic metering. This vessel is specifically designed for accurate, automated dosing, weighing and homogenization of raw materials. A counter-rotating agitator with spring-loaded nylon scrapers, which continuously clean the sides and bottom of the vessel, effectively prevents sugar crystallization and build-up while ensuring optimum mixing performance. Once weighed, the ingredients flow by gravity into the secondary mixing vessel below. This vessel, also equipped with an agitator, maintains the consistency and quality of the mixture prior to the grinding stage.

VERSIONS

| Duyvis BMV 500 | |

|---|---|

| Batch Capacity [l] | 500 |

| Connected Load [kW] | 5.9 |

CHOC LINE

QCHOC LINE