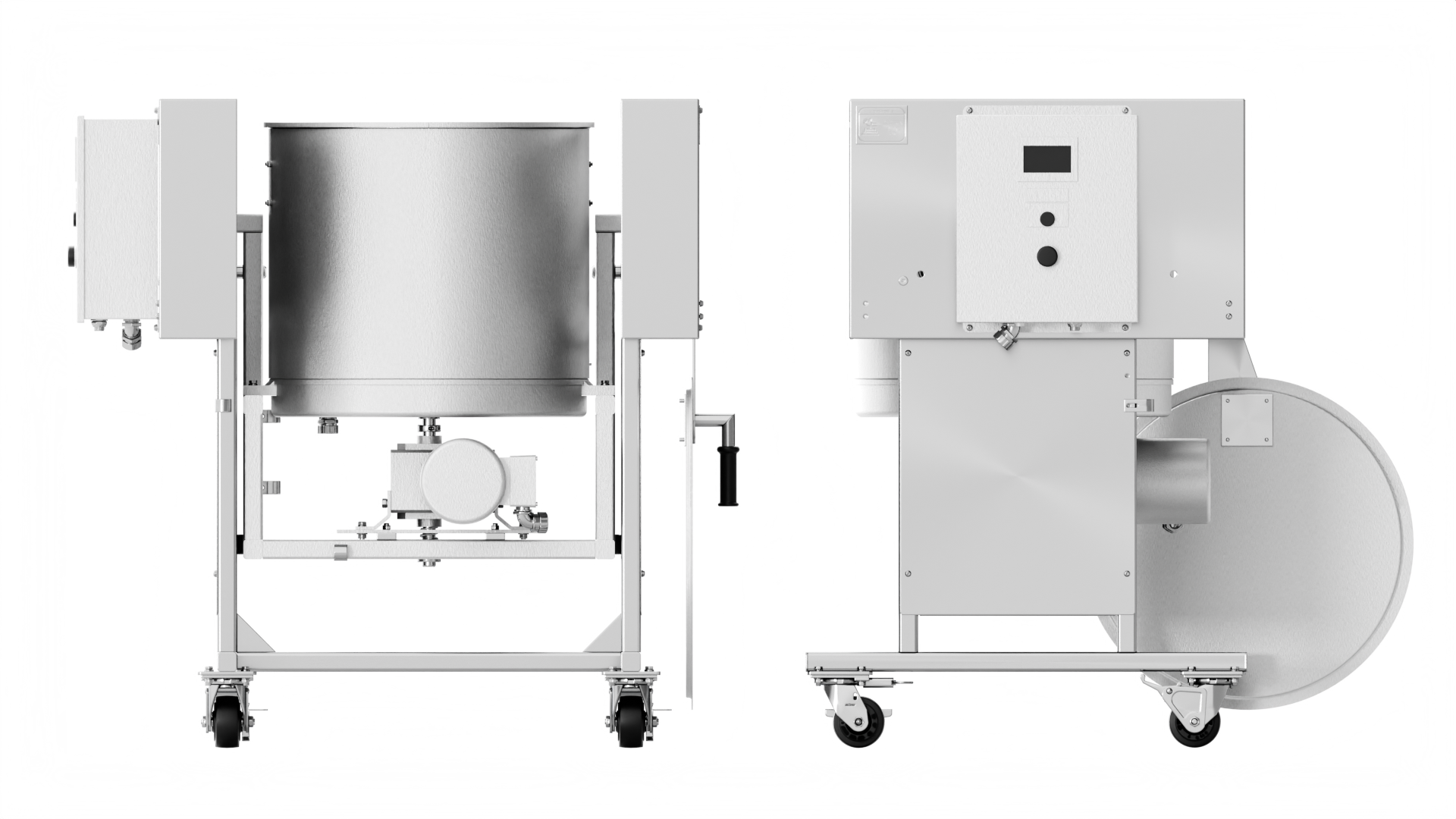

M320-K Cooker/Coater

Coating of popcorn

Built to solve. Designed to deliver.

The Horn M320-K Popcorn Cooker/Coater is a powerful, high-performance machine designed for the efficient production of premium-quality caramelized popcorn, oil-popped corn and kettle corn. It is also ideal for small-batch, slurry-based coatings, making it the perfect solution for producing peanut brittle, and a variety of other coated snacks with exceptional consistency and flavor.

The M320-K is engineered to deliver exceptional consistency and efficiency in popcorn production. First, the slurry is expertly mixed and heated inside the machine's drum. Once the pre-programmed temperature set point is reached, pre-popped corn is added. The variable-speed agitator then gently folds the popped corn into the caramel syrup, ensuring each kernel is evenly coated to perfection.

For suppliers producing kettle corn, the M320-K offers an optional kettle corn agitator. In this process, oil, popcorn kernels, and sugar or salt are added into the pre-heated kettle. The kettle corn agitator then delicately blends the oil-popped corn with the other ingredients, evenly coating each kernel for a perfect balance of flavor and texture. Once the popcorn is fully coated, it is effortlessly transferred to a cooling table for separation and cooling.

With its unparalleled versatility, the M320-K is ideal for suppliers producing a wide range of specialty popcorn varieties. By combining both cooking and coating processes in a single machine, it optimizes output and ensures consistent, high-quality results every time.

Versions

| Horn M320-K | Horn M320-K | Horn M320-K | |

|---|---|---|---|

| Product | Kettle corn | Oil-popped popcorn | Caramel corn |

| Capacity [kg/h] | 57 | 31 | 57 |