CRL Continuous Roaster Louver / BDB Batch DeBacterizer

Roasting and debacterizing of raw cocoa beans for bean processing

Built to solve. Designed to deliver.

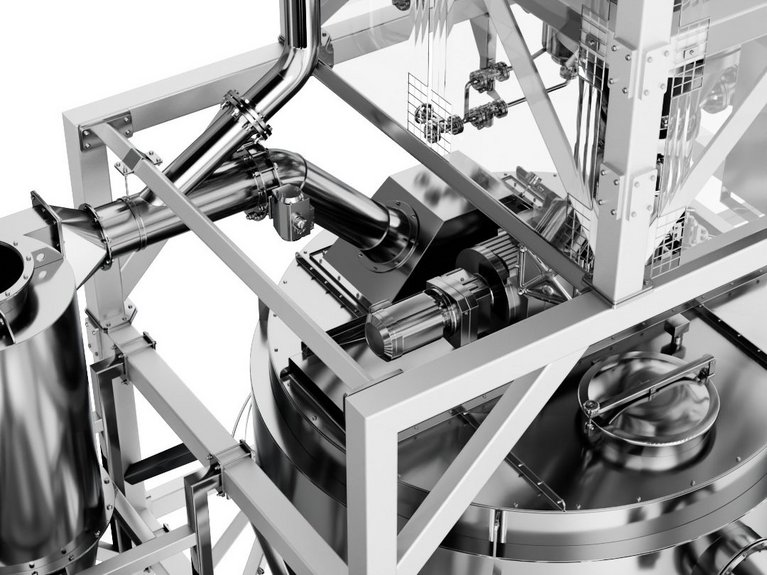

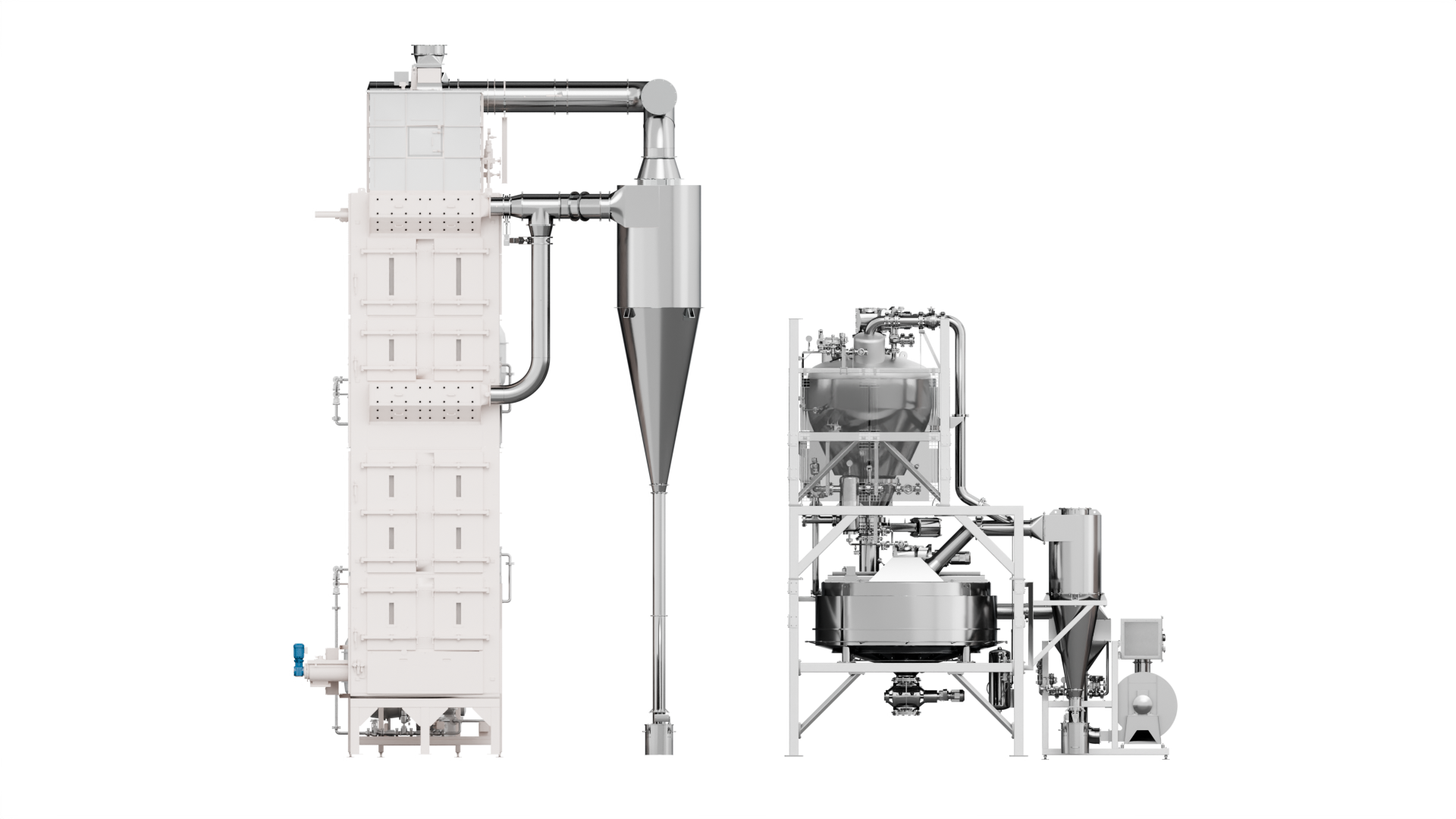

In the continuous bean roasting process, winnowing is conducted after roasting. To ensure optimal hygiene, a dedicated sterilization step is introduced prior to winnowing. The Lehmann CRL Continuous Roaster Louver is engineered for premium cocoa bean roasting, enhancing distinctive, product-specific flavor profiles. For effective debacterization, the Lehmann BDB Batch DeBacterizer precisely controls critical parameters throughout the process.

The CRL Continuous Roaster uses a counter-current hot air system. Cocoa beans are gently fed from the top and pass through multiple levels as they fall. Meanwhile, hot air rises in the opposite direction, ensuring efficient heat transfer and consistent roasting. The integrated humidity and moisture control system, accessed via the Humidity Monitoring Cockpit, optimizes the Maillard reaction by precisely regulating the drying speed, unlocking rich, complex flavor development in every batch.

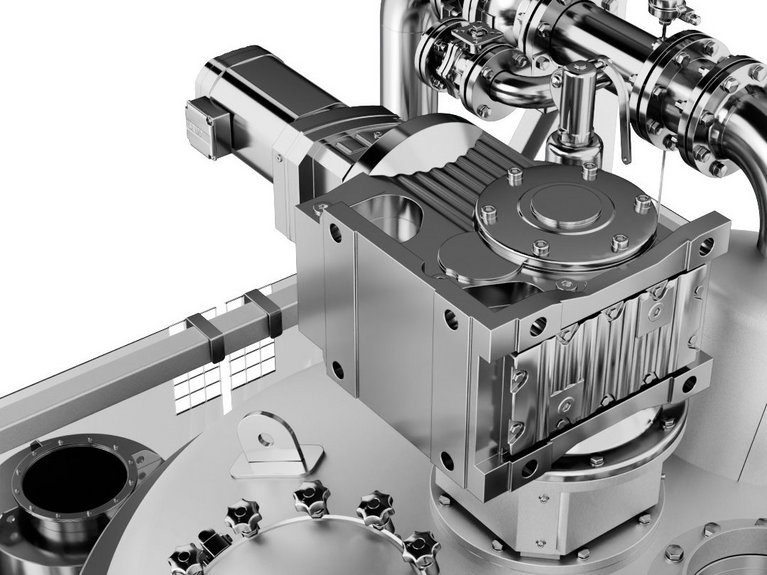

For effective debacterization, the downstream BDB Batch DeBacterizer precisely controls critical parameters—steam, heat, and time—ensuring reliable monitoring of all critical control points (CCPs) throughout the process.

VERSIONS

| Versions | Lehmann CRL/BDB 1000 | Lehmann CRL/BDB 2900 | Lehmann CRL/BDB 4000 |

|---|---|---|---|

| Capacity [kg] | 750-1,000 | 2,000-2,900 | 2,900-4,000 |

| Steam requirement [kg/h] | 800-900 | 1,800-2,000 | 1,800-2,000 |

| Connected load [kW] | 71 | 90 | 118 |