MDB Microbatch DeBacterizer / CRS Continuous Roaster Shaft

Debacterizing and Roasting of raw cocoa beans for bean processing

Built to solve. Designed to deliver.

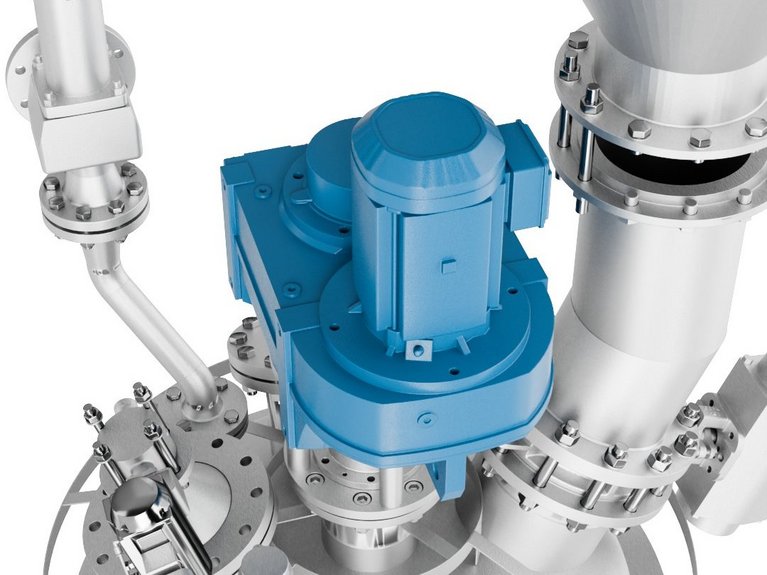

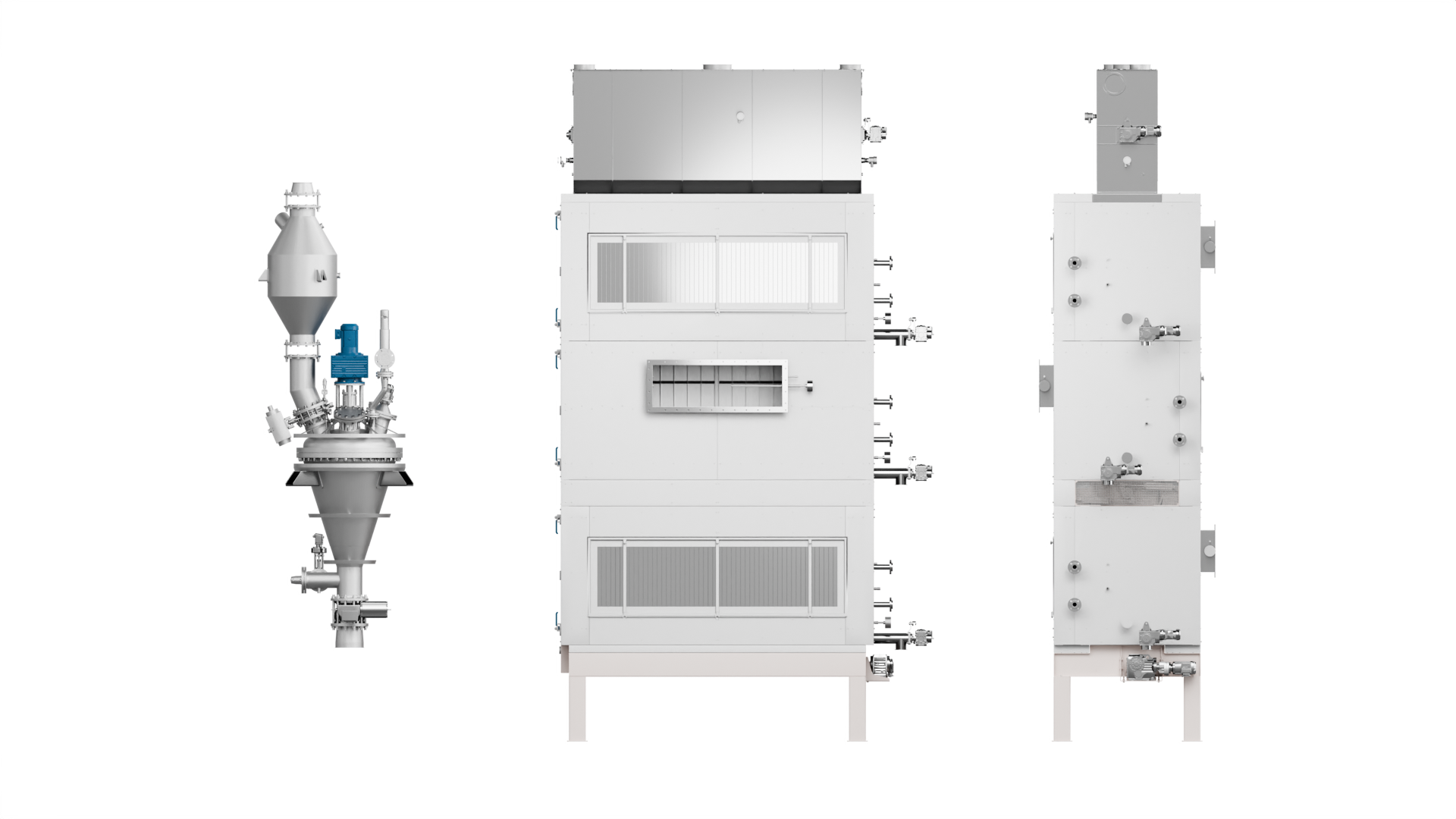

In the continuous roasting process, cocoa beans are winnowed after roasting to preserve the integrity of their distinctive flavor. To meet the highest hygiene standards, a dedicated sterilization step precedes roasting. The PROBAT MDB Microbatch DeBacterizer ensures food safety with precision, reliably controlling critical process parameters throughout.

The PROBAT CRS Continuous Roaster Shaft is engineered to deliver consistent, high-quality results across a wide range of roast levels. It enhances the unique flavor profiles of individual products, making it the ideal solution for roasting premium cocoa.

For batch sterilization, the BDB Batch DeBacterizer ensures effective microbial reduction by precisely managing steam, heat, and exposure time, while continuously monitoring all critical control points (CCPs) throughout the process.

The CRS system features up to four independently controlled heating zones and an optional cooling zone, allowing the roasting process to be stopped with pinpoint accuracy. A compact, vertically flowing bed of cocoa beans is evenly roasted as alternating streams of hot air cross the downward bean flow, ensuring uniform heat distribution.

Roasting begins with a gentle drying phase at approximately 100 °C, followed by a controlled temperature increase to develop the desired flavor profile. The optional Humidity Monitoring Cockpit enables fine-tuning of the Maillard reaction, unlocking deeper, more nuanced cocoa notes — a hallmark of continuous roasting.

VERSIONS

| PROBAT MDB/CRS 2000 | PROBAT MDB/CRS 3000 | PROBAT MDB/CRS 4000 | |

|---|---|---|---|

| Capacity [kg/h] | 2,000 | 3,000 | 4,000 |

| Steam requirement [kg/h] | 900-1,000 | 1,350-1,500 | 1,800-2,000 |

| Connected load [kW] | 69 | 92 | 115 |