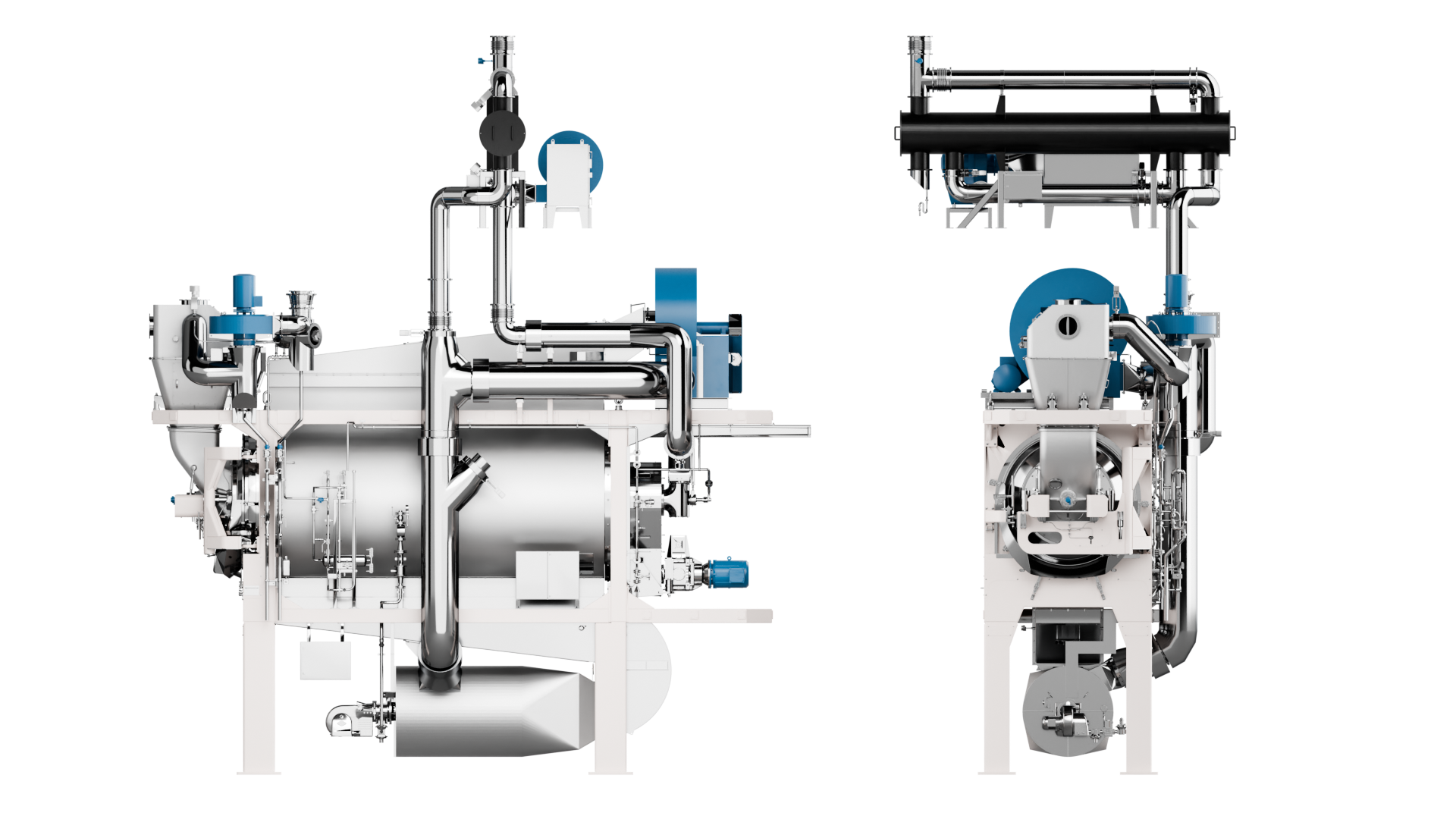

BRN Batch Roaster Nibs

Roaster for alkalized or natural cocoa nibs

Built to solve. Designed to deliver.

The Duyvis BRN Batch Roaster Nibs combines the benefits of high-capacity nib roasting with superior flavor development. Recipe changes can be easily made between batches.

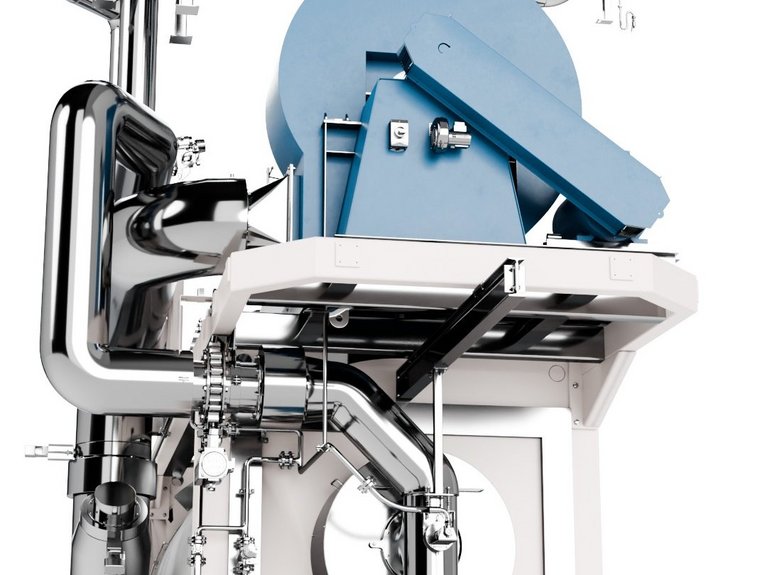

The nibs are gently roasted in a rotating drum by thermal conduction, with direct contact between the product and the drum surface and no exposure to combustion gases. The hot air is evenly distributed around the drum, promoting an even temperature distribution along its length, allowing a slow, controlled drying process.

Direct air heating and precise water dosing optimize atmospheric control, enhancing Maillard reactions, reducing unwanted volatiles, and minimizing fines to prevent overroasting. Fresh air convection ensures safe, contamination-free processing.

Versions

| Duyvis BRN 3500s | Duyvis BRN 3500i | Duyvis BRN 5000s | Duyvis BRN 5000i | |

|---|---|---|---|---|

| Roasting capacity natural [40-60 min kg/h] | 3,500-5,200 | 3,500-5,200 | 5,000-7,500 | 5,000-7,500 |

| Roasting capacity alkalized [90-120 min kg/h] | 1,750-2,300 | 1,750-2,300* | 2,500-3,300 | 2,500-3,300* |

| Batch size [kg] | 3,500 | 3,500 | 5,000 | 5,000 |

| Connected load [kW] | 89 | 104 | 108 | 123 |

*Throughput of > 10% can be obtained with additional air injection