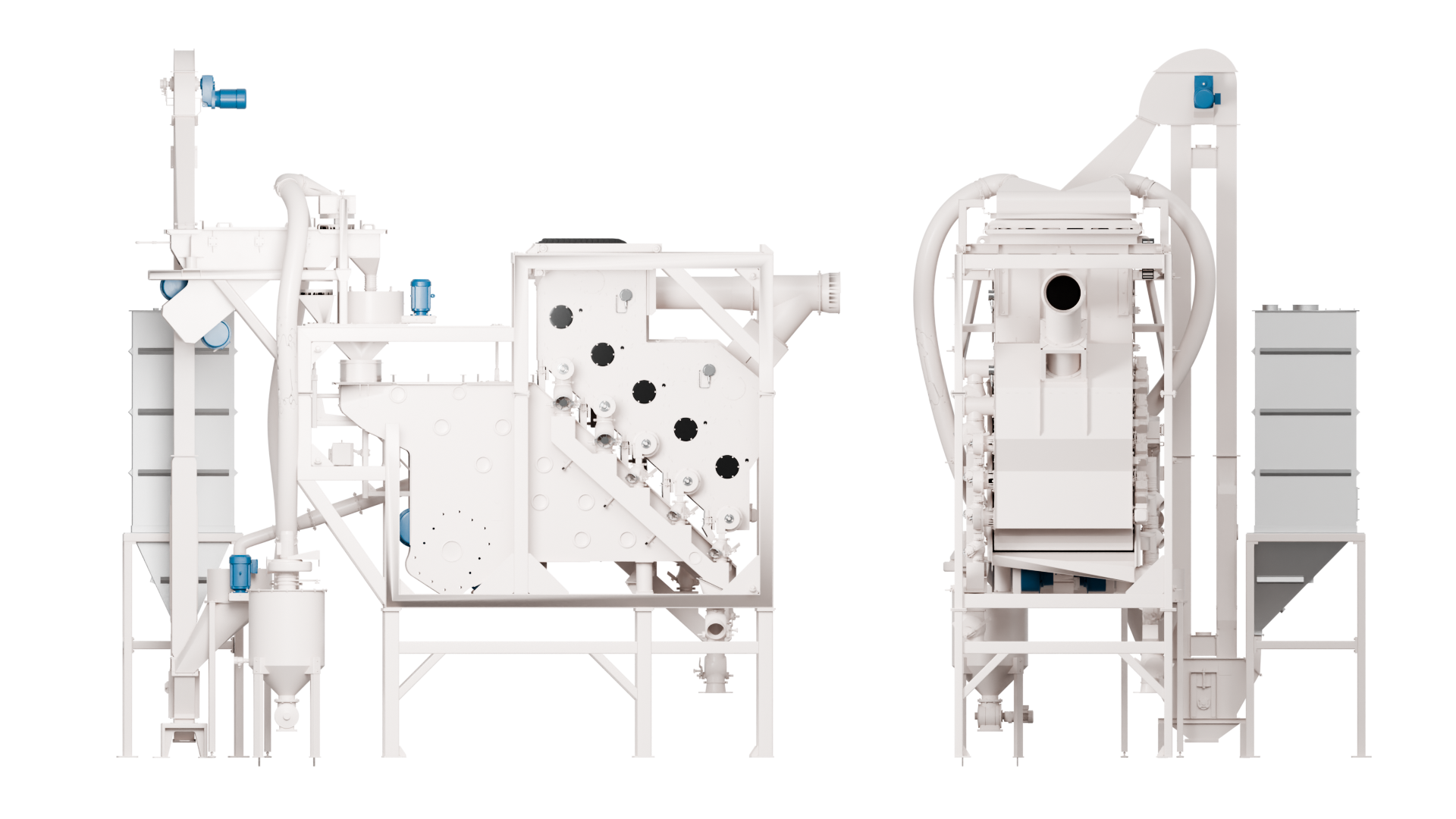

CBW Continuous Breaker Winnower

Crushing of pre-treated or roasted cocoa beans

Built to solve. Designed to deliver.

The Bauermeister CBW Continuous Breaker Winnower is purpose-built to process pre-treated or roasted cocoa beans through gentle crushing, ensuring excellent shell/nib separation with minimal dust generation. Integrated optical online monitoring supports real-time quality control and maximizes yield. The two different crushing technologies used - centrifugal crusher first and reflex crusher second - significantly reduce fines generation within the second crushing stage.

Pre-treated or roasted cocoa beans first pass through a pre-sieving unit so that only whole beans enter the centrifugal crusher, where they are thrown against an impact surface. The brittle shells break into coarse fragments, while the nibs split along natural lines into larger pieces. The crushed material then passes directly to the screening and suction section.

The shells are separated from the nibs and the nibs are graded by size using a combination of screening and suction. Beans retained on the top screen - typically harder to break - are sent to the reflex crusher and then recirculated to the pre-screening unit. Inline optical monitoring via the Quality Yield Cockpit ensures consistent, high-yield separation at the desired quality level, regardless of bean condition.

Versions

| Versions | Bauermeister CBW 3000 | Bauermeister CBW 5000 | Bauermeister CBW 8000 |

|---|---|---|---|

| Throughput [kg/h] | 1,500–3,000 | 4,000–5,000 | 6,000–8,000 |