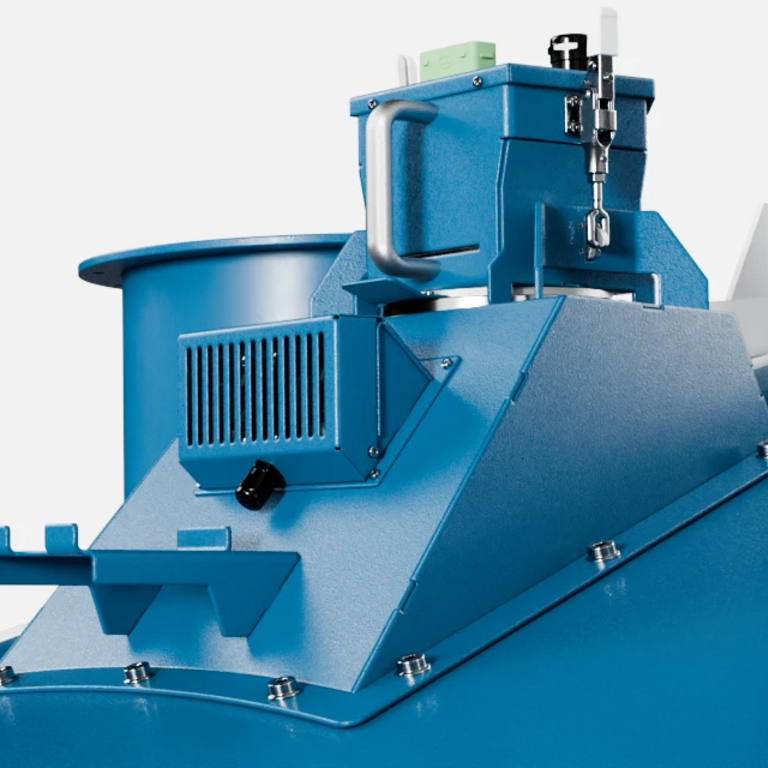

HotSpot Detection

Surface temperature control of roasted coffee batches

Maximum Process Safety

- By measuring infrared radiation across the entire surface of the roasted coffee bulk, early ember detection ensures maximum process safety.

Maximum Product Quality

- Different priority levels guarantee optimum product quality.

Maximum Efficiency

- The sensitive detection of even the slightest temperature differences enables a fast response and guarantees uninterrupted roasting cycles.

Smart sensors. Smarter Processes

During the roasting process, extreme temperatures and residual impurities can result in embers forming within the roasted coffee. If these embers are not detected, they can pose a serious fire risk when the coffee enters the cooling phase. PROBAT addresses this risk with an advanced thermal imaging solution that is designed to reliably detect hotspots early on.

Infrared thermal imaging cameras installed above the cooling sieves continuously scan the surface of the roasted coffee. Operating in the mid-infrared spectrum, these cameras measure the infrared radiation naturally emitted by objects in– this case, coffee beans – which directly correlates with their temperature.

By detecting slight temperature anomalies across the entire surface of the beans, the system can identify localised overheating or potential embers in real time. If a temperature exceeds a predefined safety threshold, the system will either trigger an alert or initiate appropriate countermeasures based on the severity of the reading.

This proactive monitoring approach enhances fire prevention, protects equipment and ensures a safer roasting environment – all without interrupting production.