P60

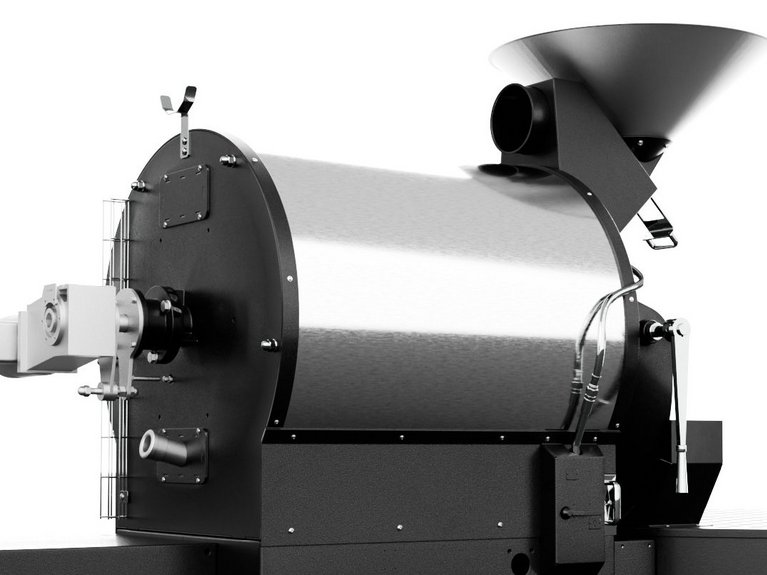

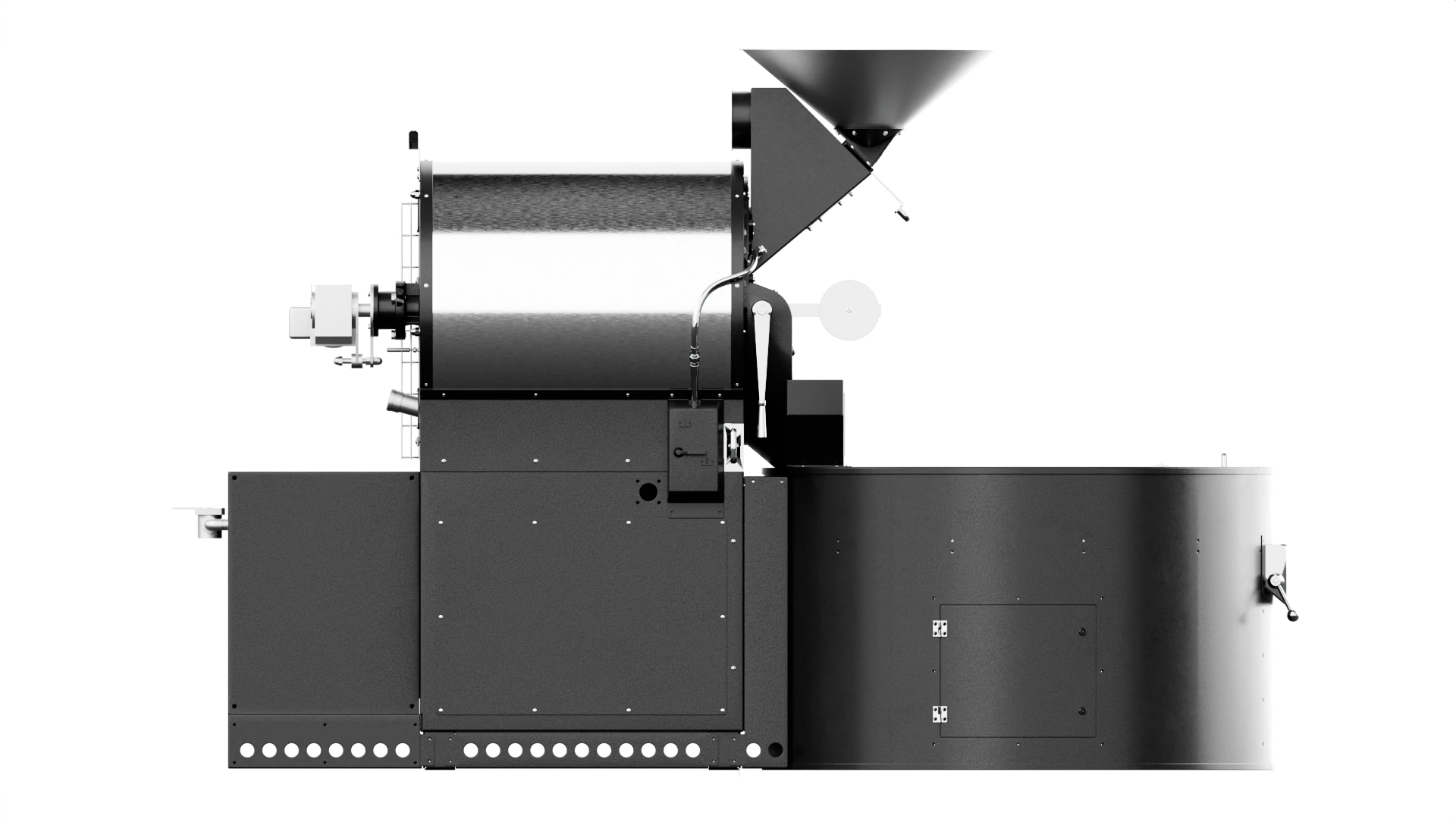

Drum Roaster

Built to solve. Designed to deliver.

Designed for artisan excellence, the P60 drum roaster is specifically crafted for gently roasting premium gourmet coffees and espressos over a long period of time. With roasting times ranging from 10 to 18 minutes, this process allows for the optimal development of aromas and the full expression of flavors. With a maximum roasting capacity of 215 kg per hour, the P60 is the ideal solution for small-scale industrial operations and larger specialty roasteries seeking consistent quality on a larger scale.

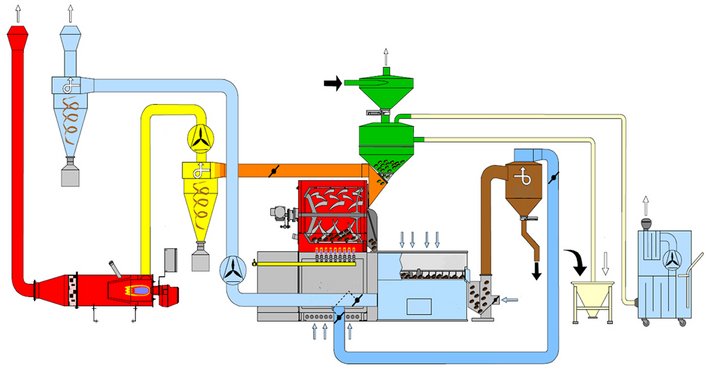

During each roast, heated supply air flows through and around the rotating drum, and specially designed internal shovel blades ensure the beans move uniformly. Heat is transferred primarily through convection, ensuring precise, consistent results every time.

| Roasting time* [min] | Roasting capacity* [kg/h] | Batch capacity* (kg) | Products | Heating | |

|---|---|---|---|---|---|

| P60 | 10–18 | 215 | 35–60 | Coffee, cocoa, nuts | Natural gas, propane, electricity, hydrogen |

* This information refers to coffee and varies depending on the processed product