Software

Redefining food and coffee processing with the PROBAT Sphere

At PROBAT, we redefine productivity by seamlessly connecting machine availability, performance and product quality. Our advanced automation solutions, powered by intelligent data management, ensure top-quality production of coffee, cocoa, chocolate, nuts and more - day after day, with peak performance, maximum energy efficiency and unparalleled plant availability.

Enter the PROBAT Sphere - an innovative ecosystem for customized automation that integrates control, monitoring and analytics. Designed to accelerate the digital transformation of your production, our platform services deliver a next-level customer experience in a data-driven world.

PROBAT Sphere

PROBAT Machine Control – Seamless Integration, Smarter Operations

PROBAT Machine Control solutions seamlessly integrate into your plant system, ensuring fast and secure data exchange for enhanced operational efficiency. Designed for intuitive interaction, PROBAT Machine Control empowers operators with responsive, customizable interfaces to monitor and control food processing machinery with ease and safety. Optimized for productivity, security, and user experience, PROBAT Machine Control revolutionizes the way users interact with industrial software.

Details and Features

-

Advanced HMI and User Management

-

State-of-the-Art Software and System Infrastructure

-

Data Management and Analysis

-

Insightful Status Tracking

-

Modern Alarm Representation and Error Documentation

-

Retrofit

-

Software Service Level Agreements (SLAs)

Advanced HMI and User Management

Simple and intuitive operation with customizable user rights. Default roles are provided for initial users, with the option to manage users directly in the HMI or via Windows domain (Active Directory). Custom roles can be created with configurable access rights per machine, ensuring full self-configuration. View multiple machines from a single interface.

State-of-the-Art Software and System Infrastructure

Web application with a modern client-server software architecture that runs on any modern device. Adaptable control concepts for single or multi-machine setups, seamlessly displaying primary and secondary machines on a single interface. Additional hardware availability for integration of multiple machines and control via a control room. Availability of a redundancy solution as an option to prevent production interruptions due to server hardware failure.

Data Management and Analysis

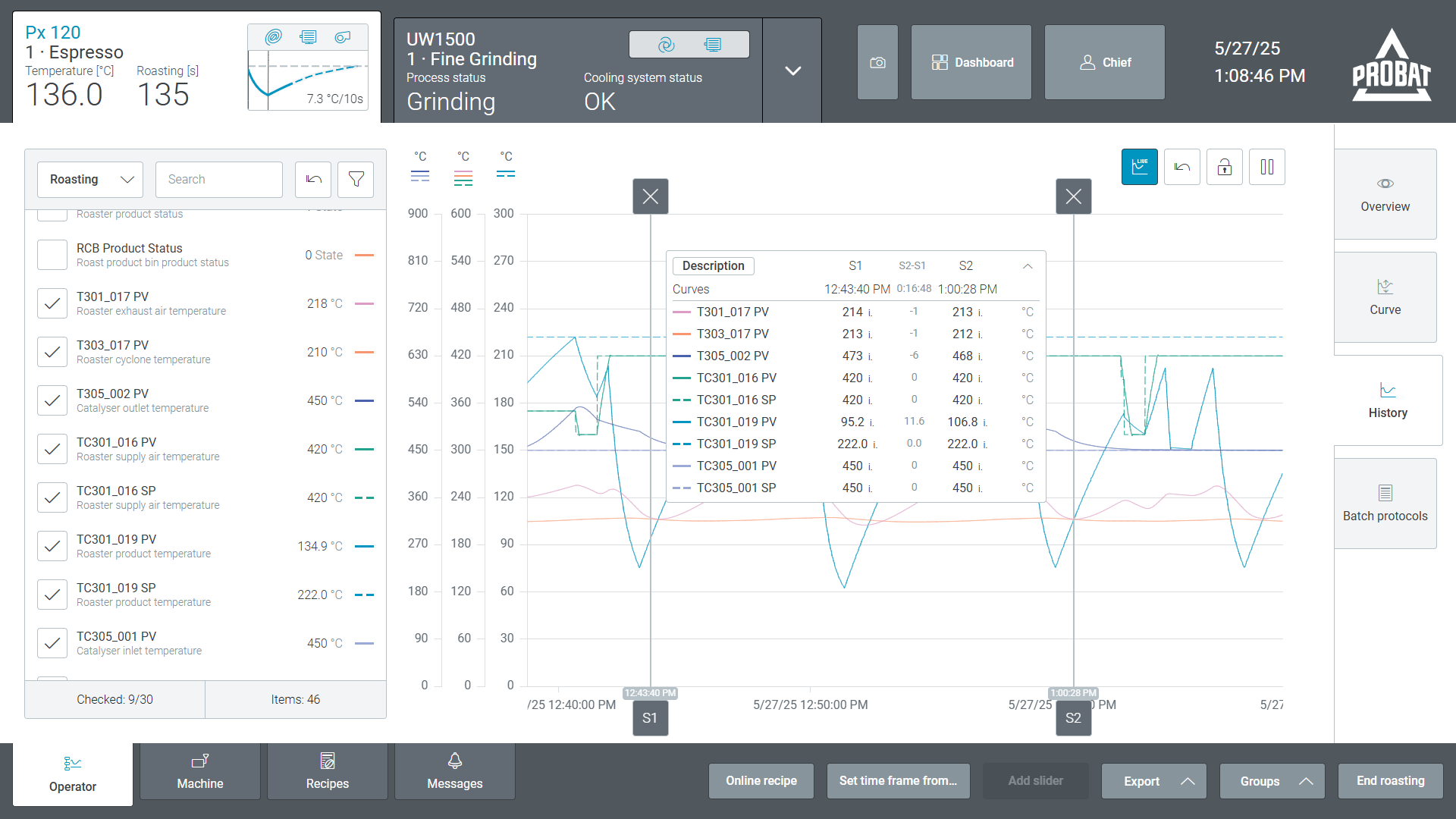

Extensive data logging allows detailed tracking of key values, making it a powerful tool for continuous optimization of processes and production quality. It also offers third party application programming interfaces (APIs), allowing you to develop customized applications. With easy integration of advanced data analysis tools, PROBAT Machine Control supports OEE analysis, maintenance tools and many other functions that improve overall operational efficiency.

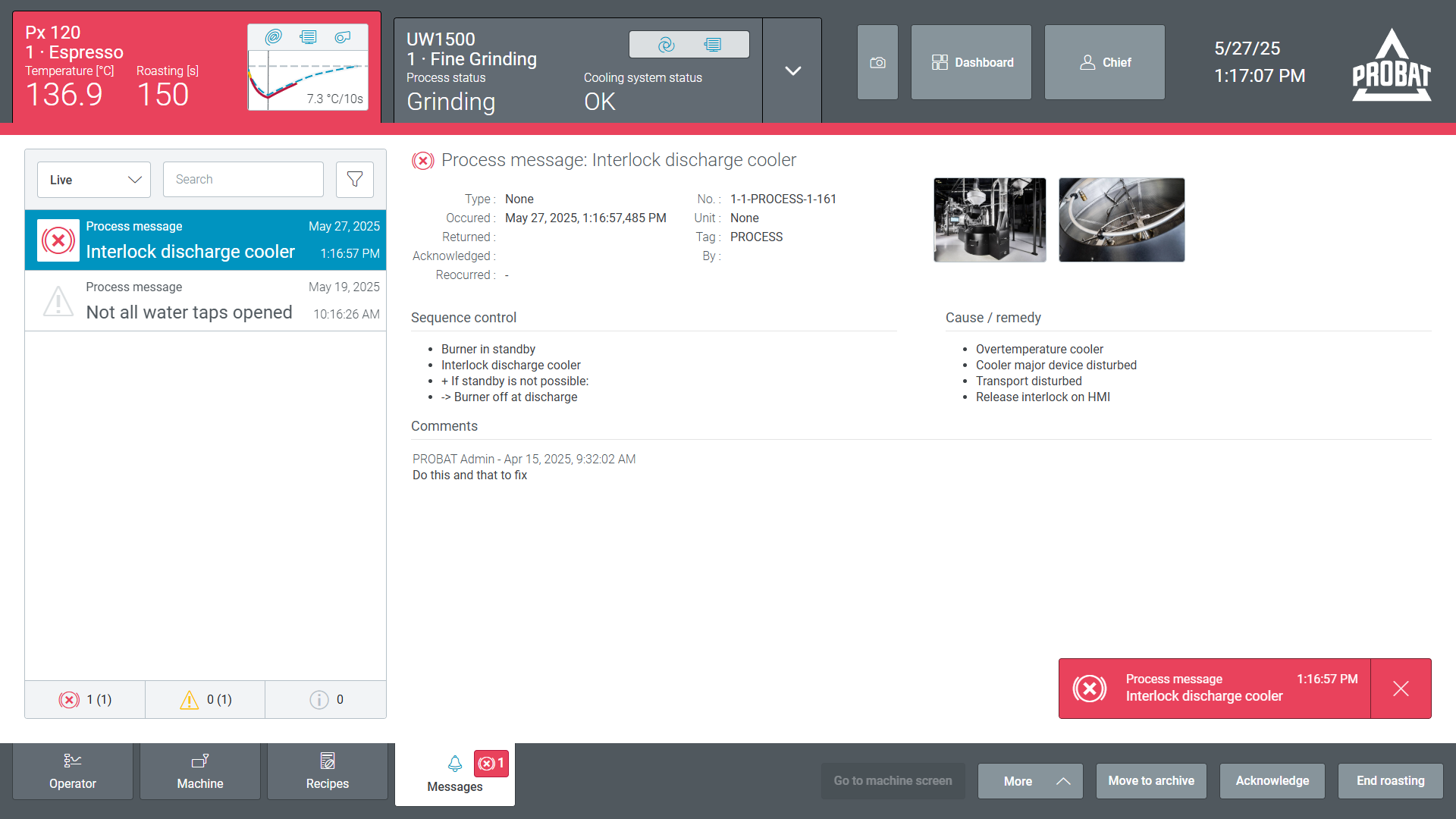

Clear Visualization of Alarm States

Alarm conditions are clearly visualized on the affected machine parts for greater clarity. A clear and easy to read display ensures quick recognition. Smooth navigation allows fast access to affected components. Color-coded highlights in the machine overview increase visibility and response efficiency.

Efficient Fault Diagnosis Through Comprehensive Documentation

Each alarm is accompanied by a description of the cause and possible consequences, enabling informed decision making. Additional information such as customized images, videos and comments can be added for personal fault documentation. Easy access to relevant information on unresolved issues simplifies troubleshooting and maintenance. A comprehensive library of descriptive text and images supports accurate fault identification and resolution.

Retrofit

Our Retrofit solutions are fully customizable, optimizing equipment performance to meet our customers' individual requirements. The solutions include upgrading control systems, replacing obsolete components with state-of-the-art technology and ensuring compliance with the latest safety and regulatory standards.

Software Service Level Agreements (SLAs)

With customized Software Service Level Agreements, PROBAT offers its customers a comprehensive and future-oriented maintenance concept that guarantees maximum operational reliability and efficiency. The combination of proactive service and individual adaptation makes PROBAT a reliable partner for sustainable and optimized production processes - today and in the future.

PROBAT Plant Control – Minimizing time to value

PROBAT Plant Control systems use the latest technologies to ensure reliable high-quality production while allowing for transparent process monitoring. By integrating all production-relevant components, they enable seamless workflows, real-time communication and modern process visualization. Modular programming increases standardization and flexibility, while intelligent energy management and quality tracking optimize the use of resources. With PROBAT Plant Control, the vision of a "Smart Factory" - where machines communicate autonomously, schedule maintenance and optimize performance - becomes reality.

Details and Features

-

Modern User Interface

-

Real-time communication and interaction with customer ERP systems

-

Tracking & Tracing

-

Order and quality management

-

Safety Concepts

Modern User Interface

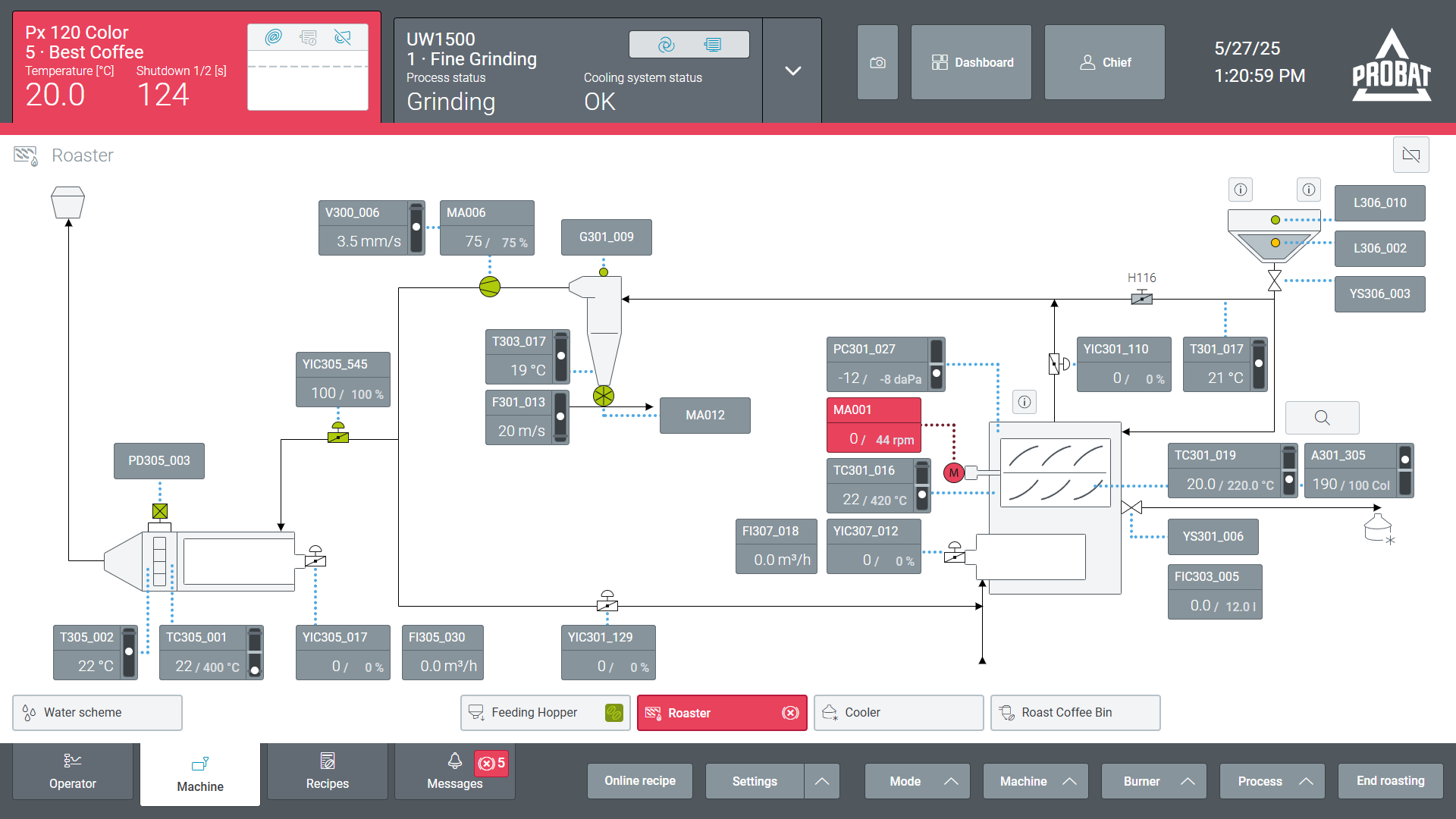

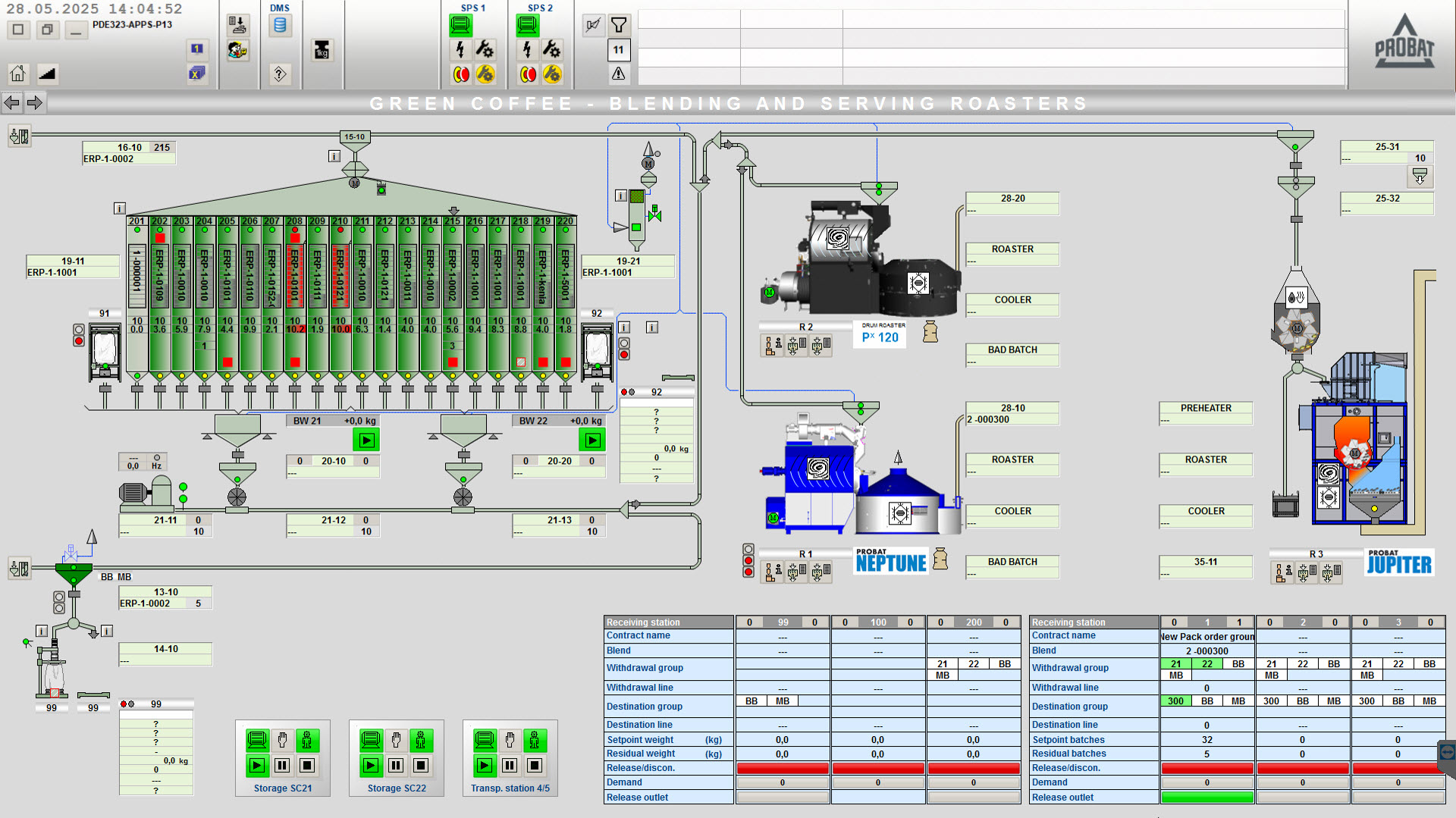

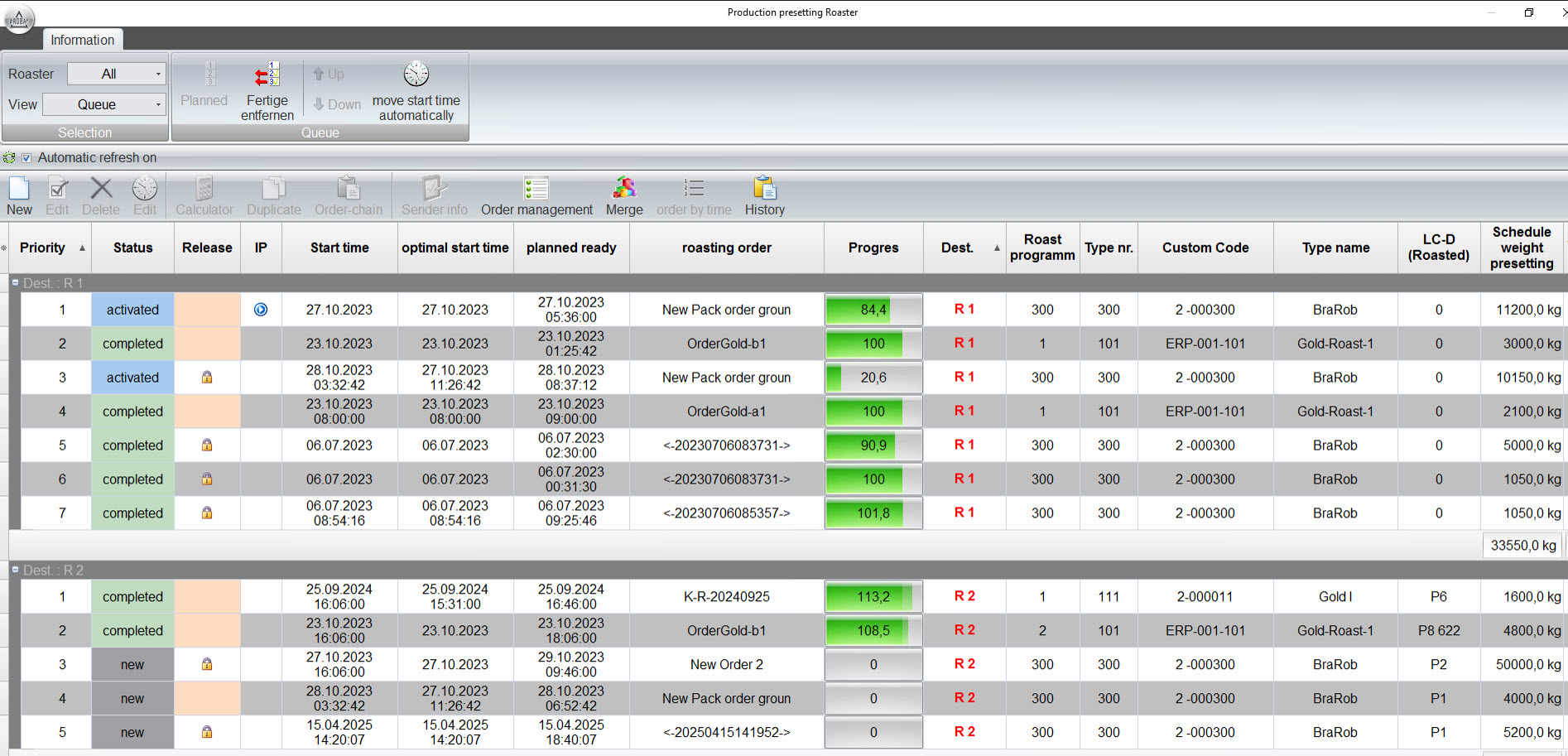

Independent, standardized HMI views smoothly merge the most important production data, which was previously only stored in the MES, into an intuitive visualization. Embedded typicals—standardized icons representing elements such as motors or sensors—provide a consistent graphical representation, while centrally configured faceplates display context-sensitive operation dialogs with critical information like system status and alarms. This design not only streamlines object display and configuration but also enables precise sensor simulation and targeted error analysis in maintenance mode, ensuring efficient and reliable plant operation.

Real-time communication and interaction with customer ERP systems

Via a reliable ERP interface, the plant control system seamlessly integrates process-relevant information - such as weekly planning - directly from the customer's ERP into the plant's MES via an exchange database. This strategic synchronization of production data with higher-level corporate planning ensures consistent product quality, complete traceability, optimized inventory control and compliance with legal regulations, which ultimately leads to greater efficiency and fewer rejects.

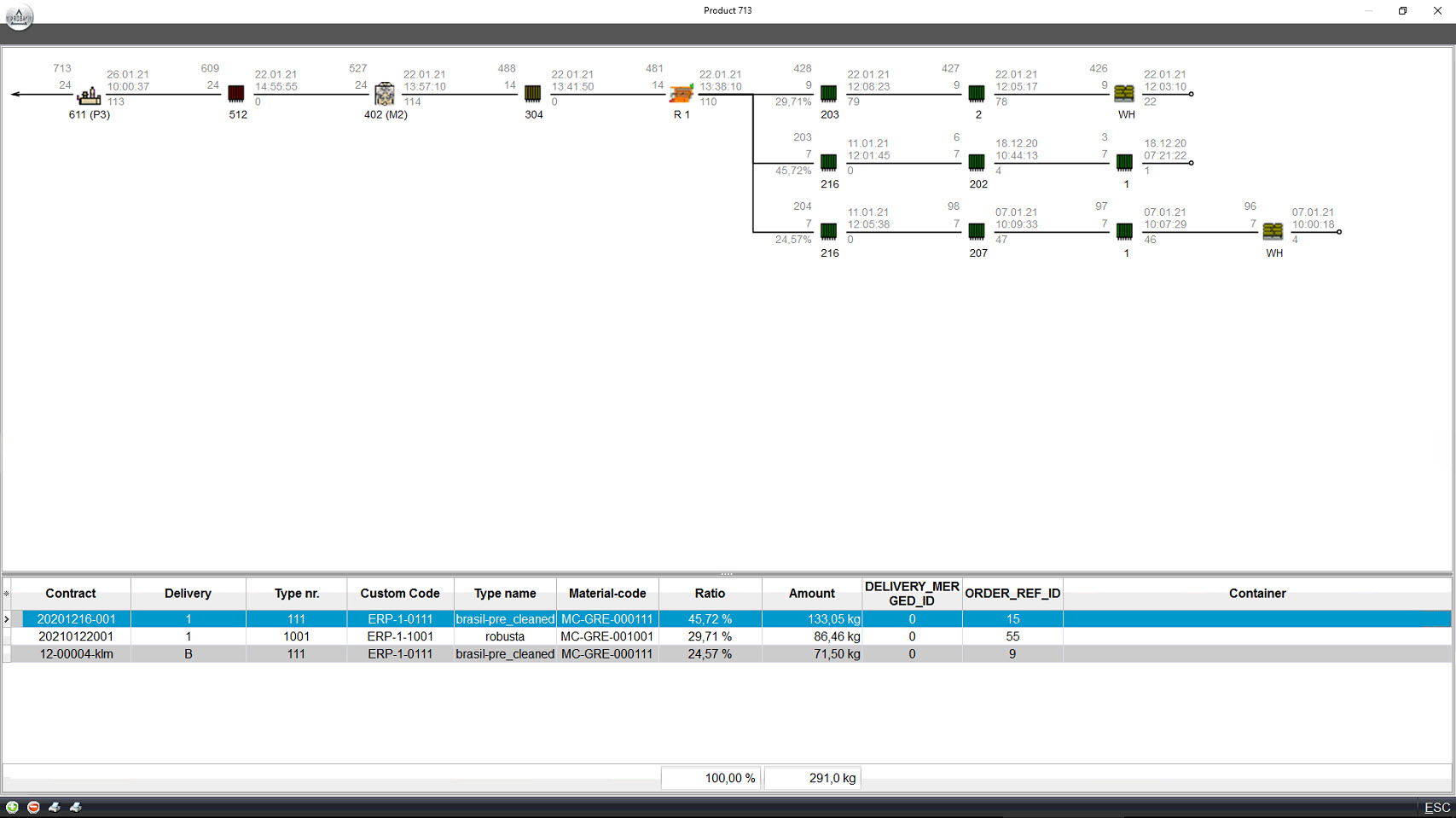

Tracking & Tracing

Continuous tracking of components from receiving to finished product, using advanced identification technologies. This data is instantly integrated into the MES, enabling accurate monitoring and comprehensive tracking of each material's journey for improved quality control and process optimization.

Order and quality management

The PROBAT MES is the backbone for an efficient, accurate and integrative work order process, as it centralizes all process-related data - from the management of different raw material types and qualities to the collection of machine and operating data. Customizable, real-time interfaces integrate seamlessly with higher-level ERP systems to ensure that resources are used efficiently, regulatory requirements are met and products are produced on time and to the required quality.

Safety Concepts

User management and a clear, intuitive alarm system ensure maximum safety. The integration of a dedicated safety PLC guarantees full compliance with all plant safety requirements. Comprehensive safety documentation supports both programming and commissioning, providing transparency and reliability. In addition, a test system is available for each project, allowing production processes and interfaces to be simulated in a controlled environment, facilitating implementation and effective customer training.

PROBAT Data Intelligence – Smart Insights for Smarter Production

Harnessing the vast amount of data that is continuously generated in food production is key to making the industry smart. PROBAT Data Intelligence is a hybrid cloud-managed service, designed to revolutionize automation in the food sector. Using advanced tools and technologies, we transform the vast amounts of production data into actionable insights. By applying artificial intelligence and machine learning to stored data, we unlock unprecedented opportunities to improve product quality and increase operational efficiency. This strategic approach enables our customers to monitor, control and optimize their production in real time, and allows us to continually evolve our systems to meet the evolving needs of the industry.

Details and Features

-

Actionable Insights

-

Scalability

-

Security

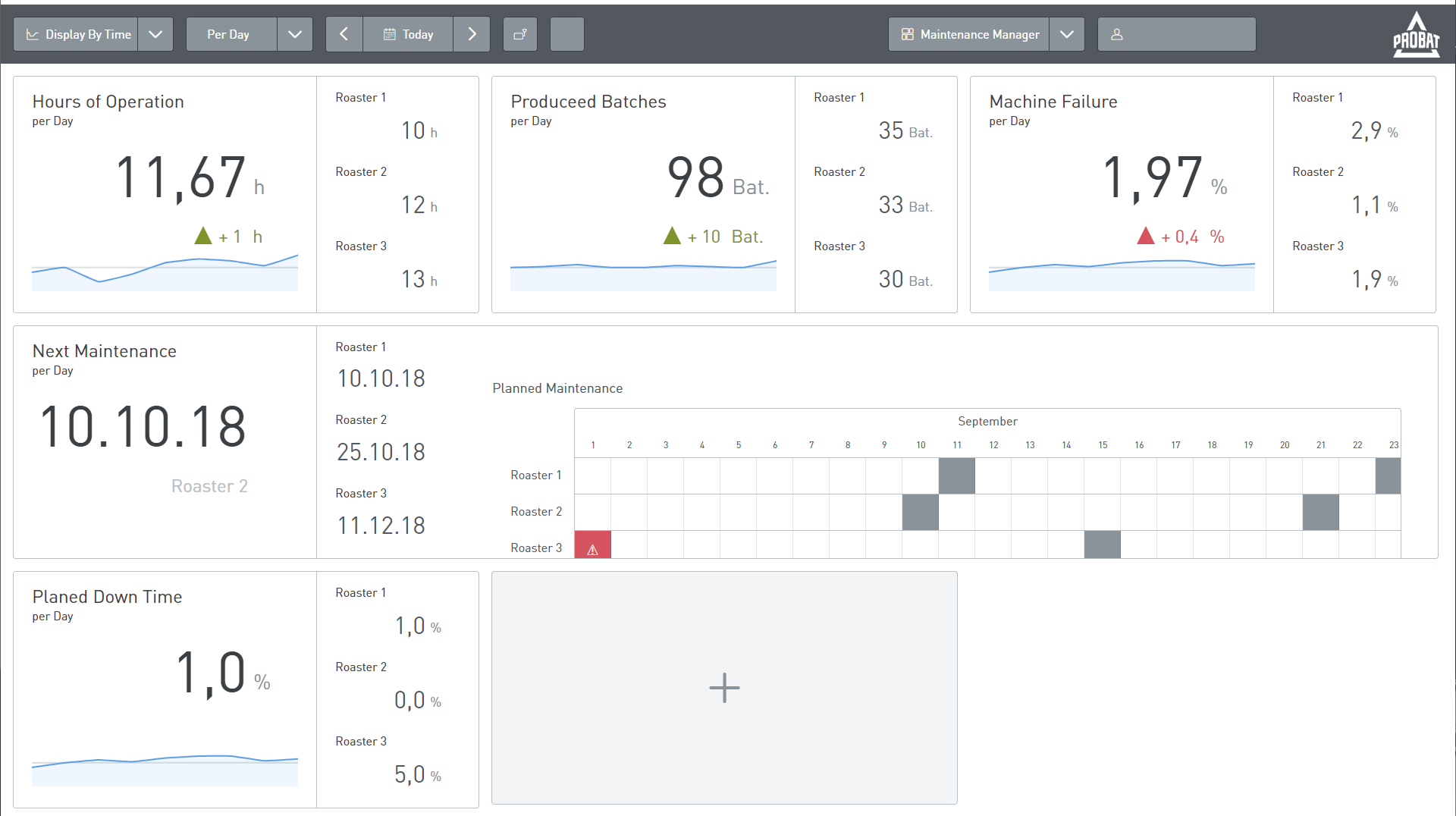

Actionable Insights

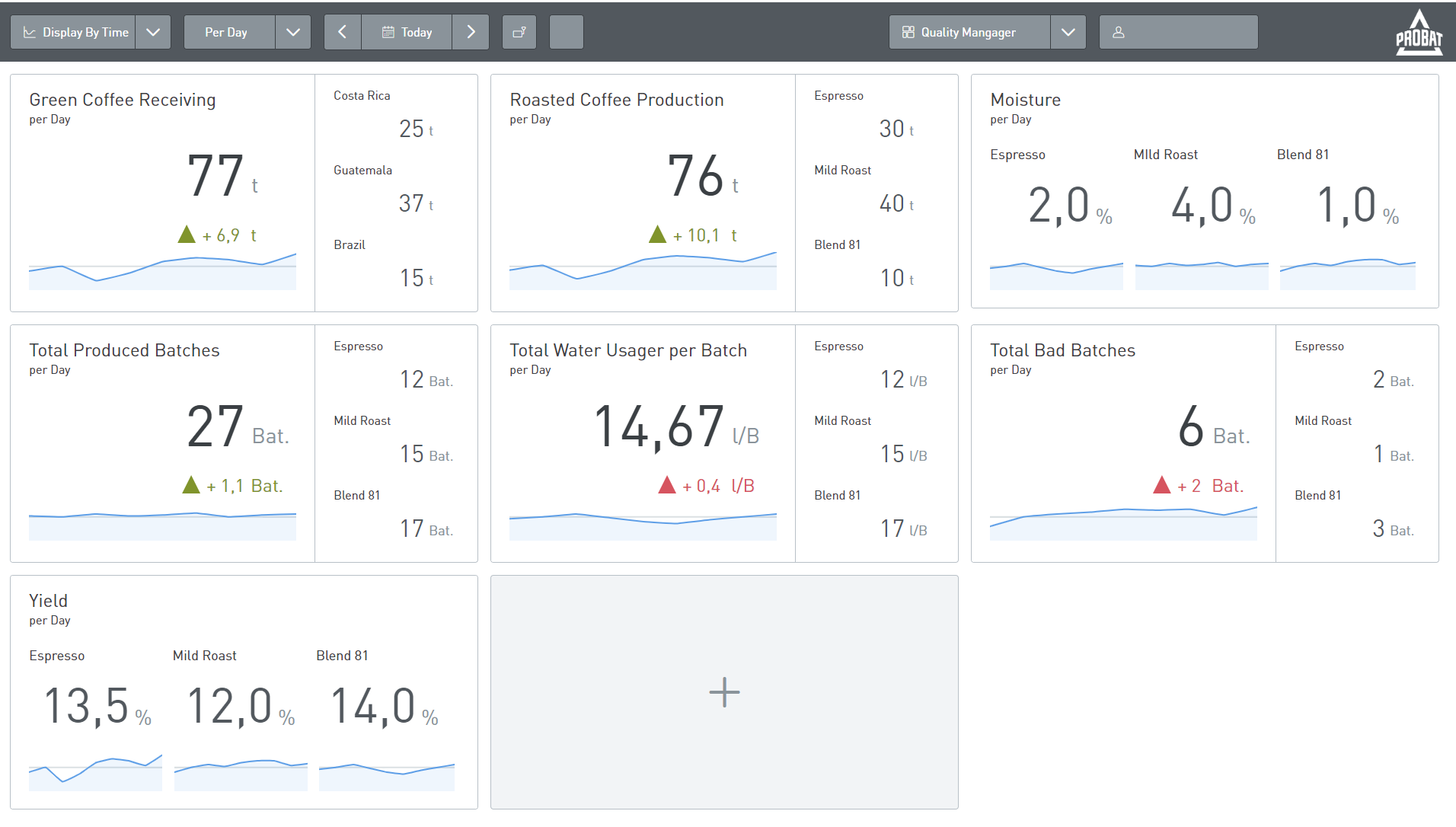

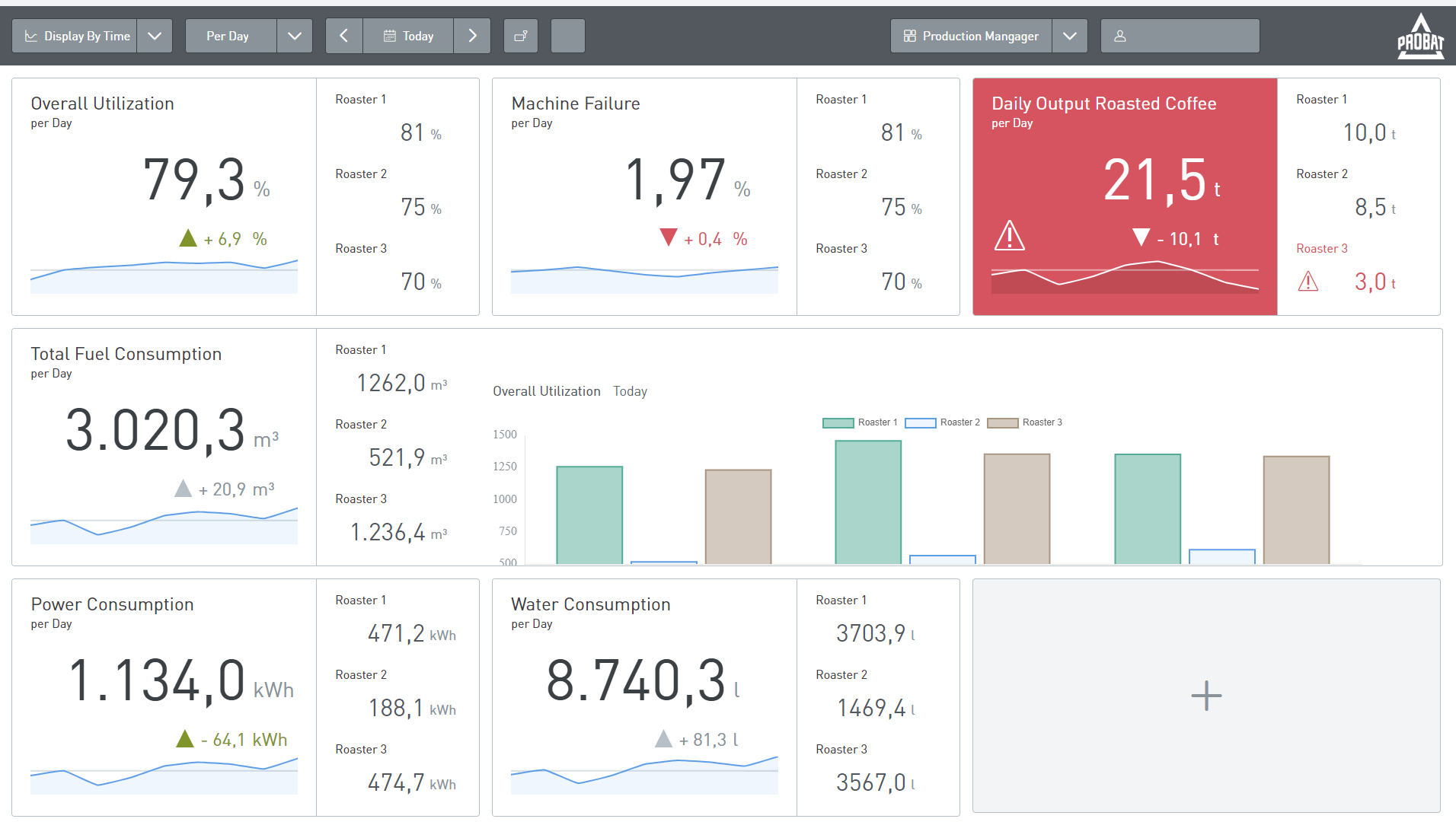

Modern food production facilities are equipped with a wide range of sensors that continuously collect various types of data - from raw material quality and the entire processing workflow to energy consumption and equipment status. PROBAT Data Intelligence analyzes this data by recognizing patterns based on dependencies and correlations, and transforms it into knowledge and actionable insights presented in easy-to-use dashboards. These cloud-based, customizable dashboards provide real-time access to production data from anywhere, enabling users across the business to make informed decisions to optimize performance, quality and availability.

Scalability

Data Intelligence is a scalable application. Significant computing power is required to analyze the vast amount of data collected from multiple sensors. PROBAT Data Intelligence provides pre-processed data, eliminating the need for an in-house IT department with high-performance computers, data analysts and software experts to extract valuable insights from existing data. As the facility expands and additional machines generate even more data, it can be seamlessly integrated into the analysis.

Security

Data is generally more secure in the cloud because the PROBAT data hub is built to the latest standards. After all, "in the cloud" simply means that data is transferred to servers in professionally managed data centers, which offer better protection against fire, burglary, unauthorized access and data loss than most non-specialized companies.