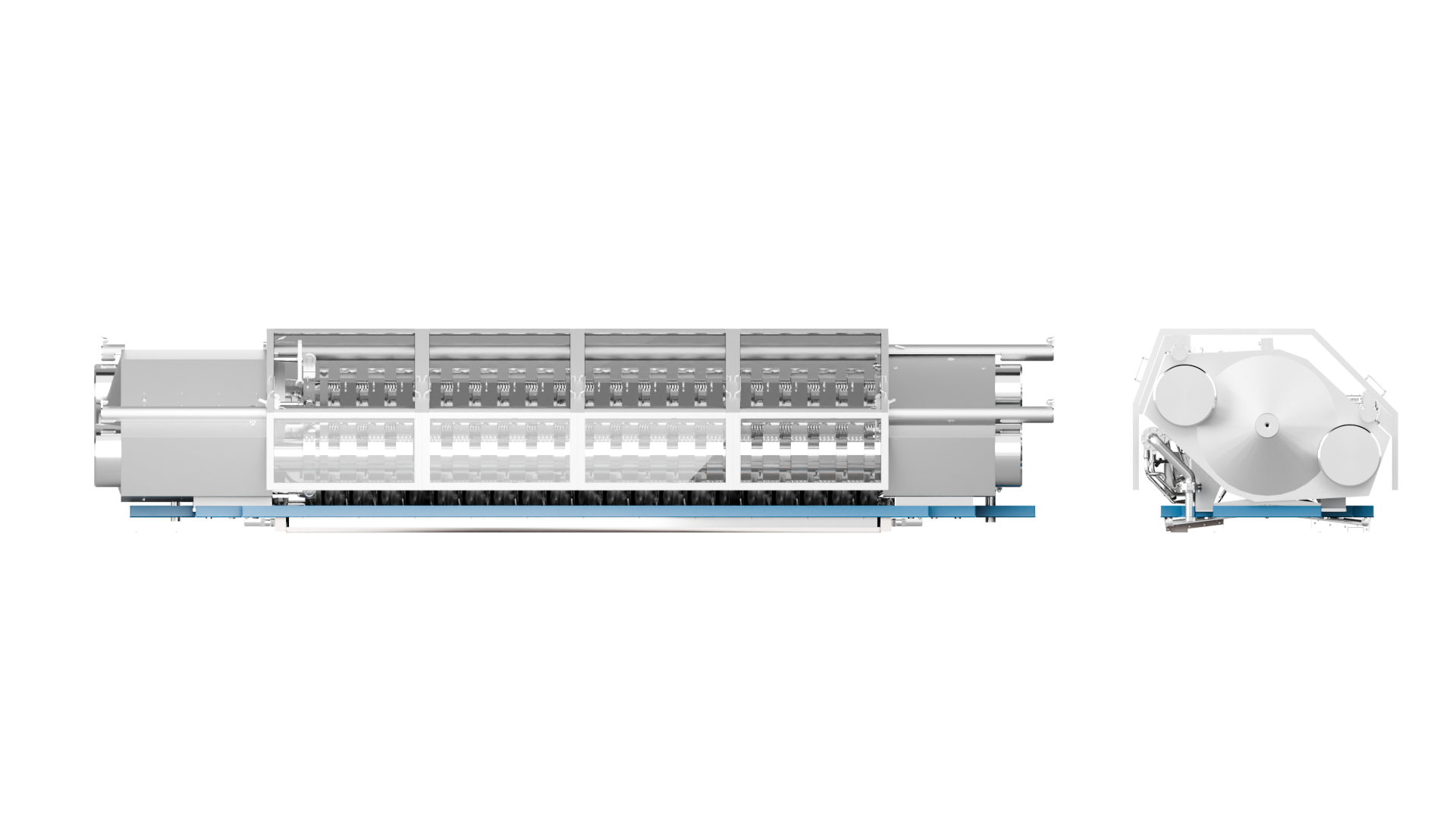

HPB Hydraulic Press Butter

Extraction of cocoa and nut butter

Built to solve. Designed to deliver.

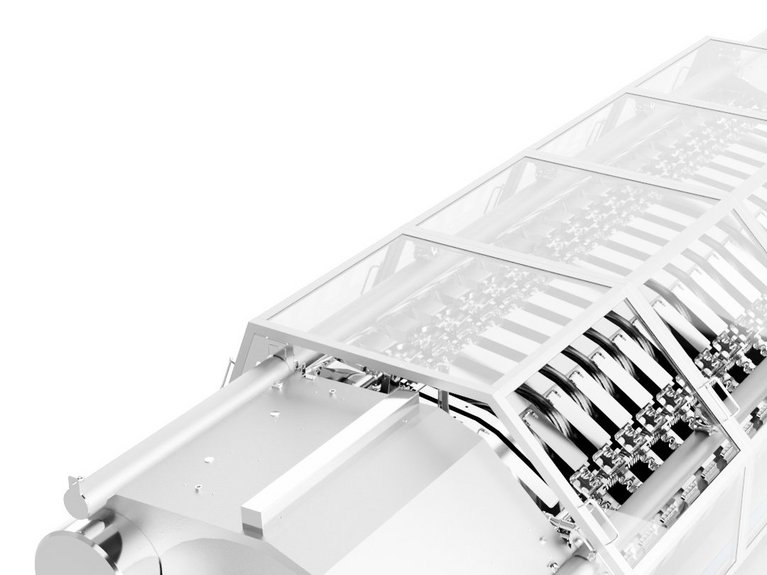

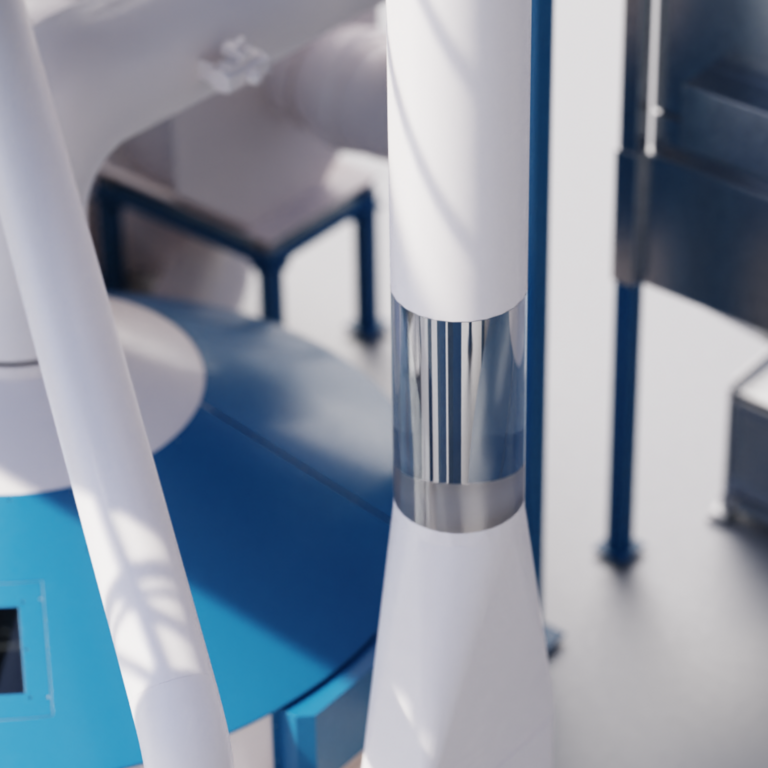

The Duyvis HPB Hydraulic Press Butter is the global industry standard for the efficient and sustainable extraction of cocoa butter. Its unique design, operation and materials deliver maximum output with minimum cycle times.

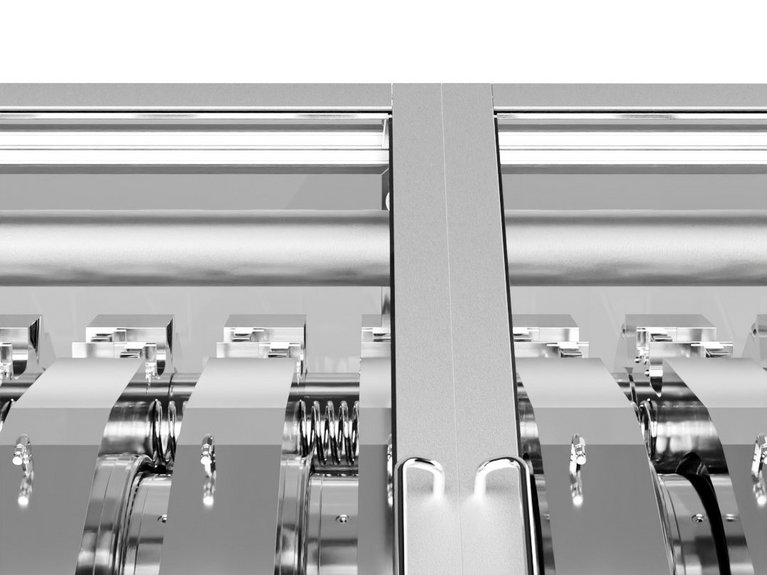

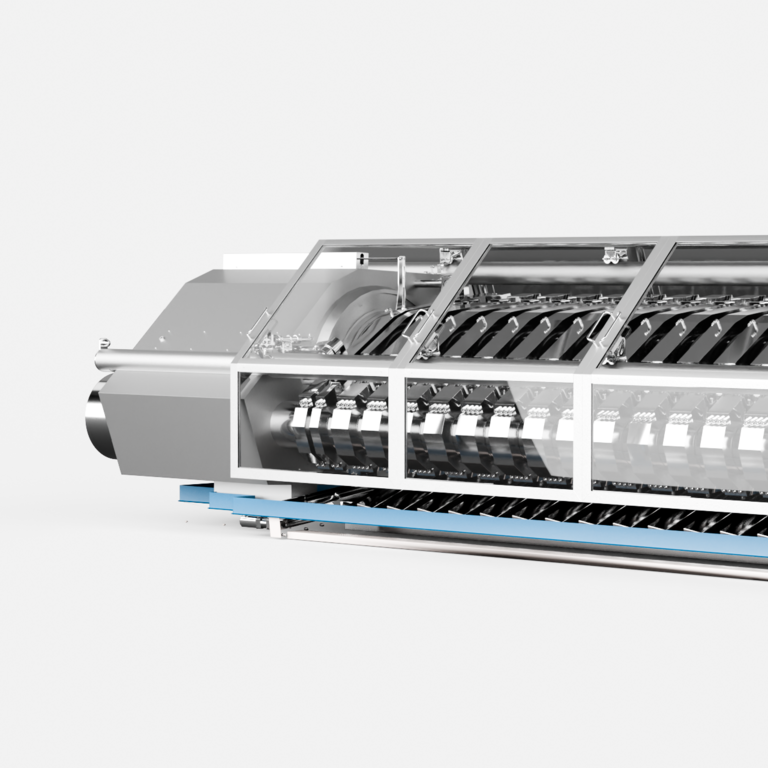

During the pressing phase, cocoa butter is efficiently extracted as it passes through the filter screens, which are precision-engineered and embedded in the press plates and counter pots. The filtered cocoa butter then flows seamlessly into drip trays and is channelled into a central conduit before being collected in a dedicated discharge vessel.

Once the pressing cycle is complete, the press opens swiftly and the residual cocoa cake is immediately discharged onto a conveyor belt. This rapid ejection minimizes cycle time and maximizes productivity. The cake is then transferred to a breaker unit where it is cut into uniform 'kibbled' pieces ready for further processing or packaging.

The HPB offers fully adjustable pressing cycles, providing precise control to accommodate the varying characteristics of cocoa liquor. This adaptability ensures consistently high-quality results, optimal fat content and consistent throughput across different production conditions.

Versions

| Duyvis HPB 1650 | Duyvis HPB 1850 | Duyvis HPB 2940 | |

|---|---|---|---|

| Capacity low-fat cake* [kg/h] | 950–1,650 | 1,050–1,850 | 2,060–2,940 |

| Capacity high-fat cake* [kg/h] | 3,000–3,150 | 3,350–3,500 | 4,860–5,340 |

| Connected load [kW] | 54 | 54 | 86 |

* This information refers to cocoa liquor pressing and varies depending on the processed product.