GOVERNANCE

Responsible corporate governance is based on transparent, ethical and effective governance structures, and forms a central pillar of our sustainability strategy.

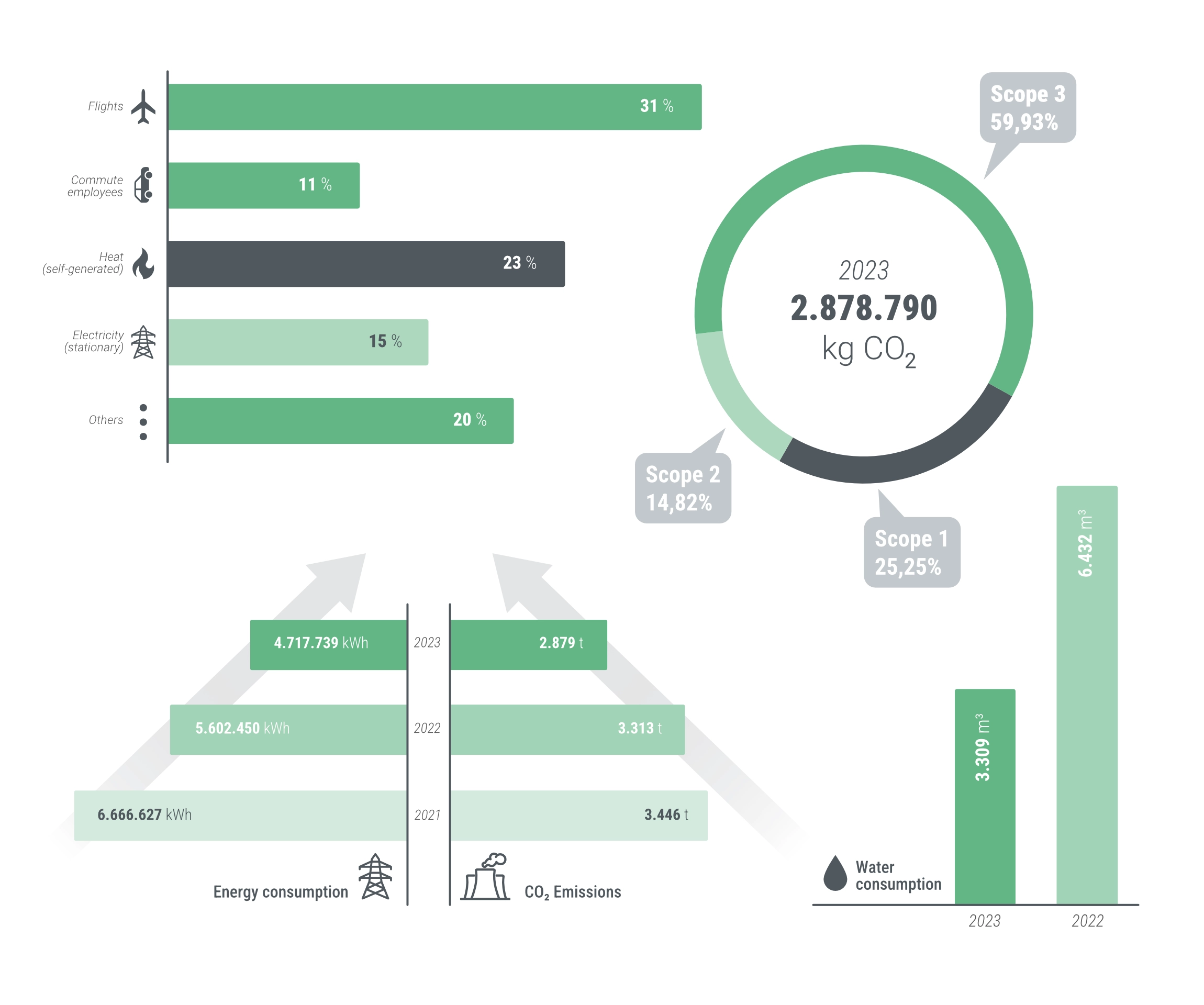

The biggest challenge currently facing global society is climate change. PROBAT has therefore also developed an ambitious climate strategy, aiming to reduce the CO2 emissions of its own operating processes to net zero by 2030. The underlying climate action plan primarily includes measures to avoid and reduce direct and indirect greenhouse gas emissions. Our ISO 14001-certified environmental management system helps us to identify further optimization potential.

We focus on energy-efficient solutions and carry out regular energy audits in accordance with DIN EN 16247-1 to identify potential savings. Since 2020, we have been calculating our site-related carbon footprint in accordance with the GHG Protocol and deriving targeted measures to avoid, reduce and offset emissions. Any unavoidable business-related air travel is fully offset.

Our water consumption is continuously monitored and optimized. We have already been able to reduce it considerably through targeted measures. We also pursue a strict waste avoidance strategy and rely on recycling and environmentally friendly disposal concepts. Hazardous substances are handled safely in order to minimize environmental impact.

Our suppliers must comply with our ESG standards and sign our Supplier Code of Conduct. We continuously analyze potential environmental impacts along the supply chain and work on strategies to reduce negative impacts. Sustainability remains a key objective of our procurement policy.

We continuously optimize our processes to increase efficiency, reduce costs and use resources in a more targeted manner. By digitizing warehouse processes and shortening material throughput times, raw materials can be processed in line with demand and with less waste. A new production layout with a Kanban system ensures lower inventories and avoids overproduction. The centralization of machines improves the flow of materials and reduces transport routes within production. At the same time, we are promoting the circular economy through targeted maintenance, reuse and recycling - for example by optimizing the maintenance of roller mills. In the long term, we are also planning to increase the use of recycled materials and “green” steel in order to further reduce our ecological footprint.

At PROBAT, we work every day to develop sustainable solutions for food processing that help to reduce emissions. A broad portfolio of environmental technologies is already making a significant contribution to continuously reducing the external effects of processing within the industry - an important multiplier effect.

Selected Environmental Technologies:

We are currently implementing further measures to minimize our ecological footprint and increase energy efficiency:

Responsible corporate governance is based on transparent, ethical and effective governance structures, and forms a central pillar of our sustainability strategy.

Social responsibility is firmly anchored in our corporate culture, inspiring us to combine long-term success with a positive contribution to society, the environment, and our stakeholders.